By Shan Raffel

Every fire sends out signals that can assist firefighters in determining the stage of fire development and, most importantly, the changes that are likely to occur. This skill is essential to ensure that the safest and most efficient firefighting strategy and tactics are employed. Being able to “read a fire” is the mark of a firefighter who can make decisions based on knowledge and skill, not guesswork or luck.

The first-arriving officer is often faced with the need to make rapid decisions with very limited information. The accuracy of these decisions is mission critical and can mean the difference between life and death.

An enormous number of factors need to be considered when sizing up a fire, and the reality is that they may not be known until days after the fire has been extinguished. People with unlimited time frames operating in a low-stress environment will judge your actions. It would be nice to think that there is a foolproof way of making the best decisions every time. The most effective approach is based on a sound understanding of modern fire behavior and how you can use the tools you have available in the most effective manner.

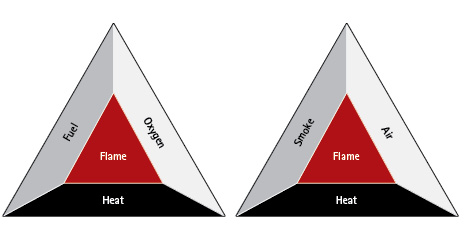

In the 1990s, firefighters were being taught to recognize the “signs and symptoms of flashover” and the “signs and symptoms of backdraft.” Although these descriptors were useful for understanding the theory, I saw the need for a simple model that could assist in rapidly determining the location of the fire, the stage of fire development, and the changes likely to occur. In 1999, I introduced a simple mnemonic that focused on the four key fire behavior indicators: smoke, air, heat, and flame (SAHF “SAFE”) (Figure 1).1 It is necessary to read the fire behavior indicators in the context of the building factors and the environmental variables. To be effective on the fireground, the risk assessment model must be simple and rapid to use.

Figure 1. The SAHF “SAFE” Model

It is necessary to read the fire behavior indicators in the context of the building factors and the environmental variables (the SAHF “SAFE” model of the fire triangle on the right).

Building Factors

The built environment is constantly changing as the demand for energy efficiency and cost-effective construction increases. Detailed information on building construction is beyond the scope of this article. All firefighters must be familiar with the common construction types in their area and understand the likely fire behavior variables.2 This risk-assessment model identifies the fire behavior indicators in terms of the fire development that is likely in that style of construction and occupancy type.

Flashover will occur in most buildings if sufficient air is available. Buildings with large single-glazed windows are likely to fail and supply additional air in the early stages of development. Lightly insulated construction will allow early heat transfer, which could lead to the early failure of structural components and thus supply air and allow superheated fire gases to spread through the structure. Heavy brick or cement rendered walls will absorb a lot of energy, which could delay flashover.

Backdraft is more likely in energy-efficient buildings with good insulation and sealed windows or double/triple glazing. Developing fires may consume the available oxygen before the fire is able to flash over. As the oxygen level decreases, the combustion process may switch from flaming to smoldering. Although the temperature of the room is high enough to support pyrolysis (100-250°C or 212-482°F),3 combustibles in the compartment will continue to release flammable vapors.

Fire gas ignition can occur in various ways. Voids, ducts, shafts, balloon frame, large open plan, high ceilings, and false or suspended ceilings are some of the factors that allow smoke to be transported and accumulate in areas adjacent to the compartment of origin or some distance from it. Modifications can create unexpected openings or voids. Poor or damaged smoke/fire stopping can be found in original or modified buildings. The unburned fuel in the smoke is often mixed with fresh air and can accumulate to flammable concentrations. If an ignition source progresses into this accumulated premixed smoke, the result can be a very sudden and extreme event.

Environmental Factors

Wind is the most critical of the environmental factors. Strong winds can accelerate fire growth and increase the likelihood of fire spread to exposures by ember attack. It can also magnify the effects of low humidity and extremes of temperature.4

The natural and built topography around the structure can cause variations in the direction and velocity of the wind on the various sides of the involved structure. Another example of extreme impact is what is known as the wind-driven fire. Strong winds blowing into a closed room can increase the pressure inside the compartment. If the compartment door is opened, the result can be a rapid and sustained flow of superheated gases into the passageway. (4)

Extreme temperature variations can have a significant impact on how the smoke released from a structure behaves. Extreme low ambient temperatures can cause rapid cooling of discharged smoke that will decrease the buoyancy. When combined with “low atmospheric pressure,” an inversion layer that will prevent the smoke from rising can form. The construction commonly found in areas likely to experience extreme cold are also less likely to show heat indicators that could be considered “common, normal, or reliable” in the type of construction commonly found in moderate climates. (4)

(1) The fire is in the bottom left compartment. The air is restricted, and the flaming combustion ceases; but, pyrolysis continues, and the smoke turns white. (Photos by author except as otherwise noted.)

Smoke

Volume and Location

Often, the human eye first notices the volume and location of smoke. Generally, this provides a guide to the fire size and location. However, smoke can travel through concealed voids and shafts and emerge in totally unexpected locations. Heated smoke is buoyant and rises vertically. When it reaches horizontal obstructions, it spreads out and looks for additional openings to allow vertical travel. Most experienced firefighters have encountered a structure releasing large volumes of smoke and later discovered that the fire area was smaller than anticipated or in a totally unexpected location. As with all fire behavior indicators, it is critical not to read this indicator in isolation.

Color

Color can vary with the type and form of fuel package, as well as the ventilation available. It may give a general indication of the efficiency of the combustion process in the room or structure.

Lighter colored smoke (sometimes almost white) is often produced when the fuel is heated to the pyrolyzation temperature. At this temperature, the volatile components of the fuel are released, and the solid carbon is left behind in the form of char. As the fire develops, heat will be transferred to neighboring compartments, which can cause the pyrolysis of linings and adjacent combustibles. White smoke will accumulate and drift into uninvolved sections of the building. Even though this smoke is at a lower temperature, it has a very high fuel content and the introduction of flames into these spaces can result in a very sudden and powerful ignition. Remember, when the application of water begins, the smoke discharged will be lighter in color because of the presence of water vapor.

Brown or yellowish smoke can be released in the early stages of the pyrolyzation of timber products. This is caused when the lignin breaks down and the tar is released as a vapor.

Dark smoke often indicates rich conditions caused by a restricted air supply. The color can be very dark if the combustion process is hindered by a lack of air or excessively fuel-rich conditions. If the air supply is good, some of the carbon will be burned in the reaction zone (flame), which will result in a slightly lighter smoke and a yellow flame.

Gray smoke indicates that at least some flaming combustion is present. When the darker smoke from flaming or smoldering combustion mixes with the whiter pyrolysis smoke, the result can be a gray smoke.

(2) A limited air supply is introduced; the flaming combustion resumes and produces a very dark smoke.

Thickness (Optical Density)

Thickness of the smoke may be an indicator of the efficiency of the combustion process. In the early stage of fire development, smoke production is less because there is a relatively good air supply. As the fire progresses to ventilation controlled, the combustion becomes less efficient, and smoke volume increases. Severely ventilation-limited fire will produce large volumes of thick dark smoke. The smoke thickness is also a function of duration. It is possible for a relatively small fire to produce a large volume of thick smoke if it has been burning for a long time in ventilation-limited conditions.

Buoyancy

Rapidly rising smoke indicates that the gases are at a high temperature. Even the dense products of combustion will be lighter than air when they are heated to high temperatures. In contrast, smoke released at a lower temperature tends to slowly drift upward, or even downwards, in cold conditions. This lower buoyancy could indicate relatively low compartment temperatures, or it could be caused by cooling that has occurred as the smoke has traveled some distance through uninvolved sections of the structure.

(3) These photos show the lowering of the neutral plane as the fire progresses toward flashover. (Photos courtesy of Tim Watkins.)

Height of the Neutral Plane

As the fire develops, the neutral plane will lower and the thickness of the smoke gases will increase. Therefore, note the following:

• A high neutral plane could indicate that the fire is in the early stages of development.

• A very low neutral plane could indicate very rich backdraft-like conditions.

• A sudden rise could indicate that ventilation has occurred.

• Gradual lowering could indicate a buildup in fire gases and an approaching flashover.

• Sudden lowering could indicate a sudden intensification of the fire.

In summary, it is critical to consider all the indicators together before jumping to conclusions. This is true of all indicators, but it is particularly important when considering smoke color.

(4) These photos show the lowering of the neutral plane as the fire progresses toward flashover. (Photos courtesy of Tim Watkins.)

Air

Air movement is typically identified when it interfaces with smoke at openings. Interpretation of the air/smoke flow paths is a critical factor in understanding the impact of existing openings on fire development and likely fire spread. This knowledge forms the foundation for effective hoseline placement and the tactical ventilation plan.

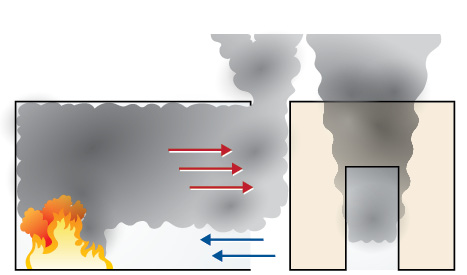

Bidirectional flow path. When an opening is created in the room on fire, the heated gases will flow out of the top of the opening and cool air will be drawn in through the bottom of the opening. Smooth or turbulent flow can be a very reliable indicator if seen emerging directly from openings in the fire compartment. If they have been travelling some distance from the fire when identified, they become less reliable in determining the burning regime.

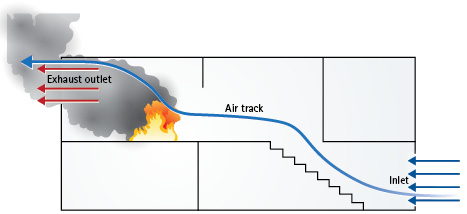

Bidirectional fuel-controlled (smooth flow). If the smoke/air track is slow and smooth, it could indicate that the fire is in the early stages and most likely still fuel controlled. This is generally associated with a high neutral plane (Figure 2).

Figure 2. Bidirectional Fuel Controlled (Smooth Flow)

If the smoke/air track is slow and smooth, it could indicate that the fire is in the early stages and most likely still fuel controlled.

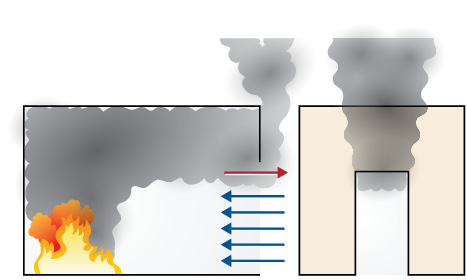

Bidirectional ventilation-controlled (turbulent flow). As the fire grows larger, the demand for air increases as does the volume of superheated smoke. Eventually, this leads to a situation where the discharged smoke blocks off the opening and restricts the ingress of air toward the fire base. This results in turbulence at the neutral plane in the opening (Figure 3). This is generally associated with a low neutral plane.

Unidirectional Smoke/Air Tracks

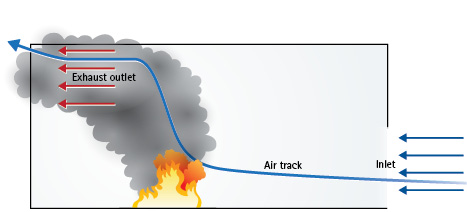

Unidirectional exhaust. Smoke or flames seen leaving an opening from the entire opening is an indicator of an exhaust outlet. For the smoke or flames to be flowing directly out of an opening, there must be inlets that are at least equal in cross-sectional area or wind being driven into the inlets.

Unidirectional inlet. Look for open doors and windows that could be feeding the fire. As previously mentioned, each unidirectional exhaust opening will require inlets at least equal to the cross-sectional area (unless the inlets are wind driven). It may be possible to reduce the rate of fire development if these inlets can be closed or restricted until hoselines are put in place.

Unidirectional alternating (wind driven). Under normal wind conditions, a room with only one opening will display a bidirectional air track, either fuel controlled (smooth flow) or ventilation controlled (turbulent). Strong winds being blown into a closed fire compartment can lead to a high-pressure zone in the compartment. This will force air into the compartment, leading to fire intensification that will result in a pressure rise that will eventually overcome the pressure created by the wind. This leads to a situation in which the opening will aggressively alternate between an inlet and an exhaust.

Figures 4. Unidirectional Flow Paths

Figures 5. Unidirectional Flow Paths

The simple unidirectional flow paths in a single room (Figure 4) and a two-story structure (Figure 5).

Pulsations

Smoke pulsing out of small openings can indicate a ventilation-controlled (or limited) fire. This indicates that there are variations in pressure because of a limited oxygen supply. As the oxygen level decreases, so does the combustion process. This, in turn, decreases the temperature and, consequently, the volume of the gases decrease. This causes air to be drawn in, the fire starts to increase, the temperature of the gases increases, and the expanding smoke is pushed out through the gaps under pressure until the air is consumed and the cycle starts again. In some cases, this could develop into a situation where the sudden opening of the compartment could lead to backdraft. This may be combined with whistling noises as air is being pushed in and out through small gaps. Remember that it might be difficult to notice this with background noise.

Heat

The initial assessment should include looking for indicators of high temperatures. Heat indicators are likely to be evident in building construction. Heavy, well-insulated construction is less likely to show heat indicators in the early stages.

Windows

The window indicators are most reliable with single-pane windows. Many of the heat indicators may not be easy to identify in double- or triple-glazed windows.

Soot-stained windows with little or no flame showing. The blackening indicates rich conditions (backdraft potential) and is often accompanied by oily deposits on the inside of the window (photo 5).

(5) Cracked glass from rapid heat buildup.

Cracking or crazing of glass. Rapid heat buildup can crack glass. Crazing (finer cracks) can be seen when the heat buildup has been slower; crazing is often accompanied by heavy blackening and oily deposits (photo 6).

(6) The blackening indicates rich conditions (backdraft potential) and is often accompanied by oily deposits.

Blistering or discoloration of paintwork or cladding. This indicator is often present in lightweight internal doors. Heavy, well-insulated exterior doors are much less likely to show this indicator. Initially, feeling the door surface and door handle may help to detect developing heat conditions.

Sweeping a water spray across a lightweight door or surface can also be used to test for surface heat. If the door is hot (higher than 212°F/100°C), the film of water on the upper section will rapidly evaporate. In some cases, it is possible to get an indication of the height of the neutral plane by observing the line at which the evaporation ceases (photo 7).

(7) Blistered and discolored paint on an internal door.

Sudden Heat Buildup

This is frequently quoted as an indicator that flashover or backdraft is impending. If you are waiting for this indicator, it is likely that you have missed the other fire behavior indicators! This is a late indicator, as it often occurs after some form of fire gas combustion (rollover) has commenced in the ceiling area. This may be difficult for the firefighter to see and will not give adequate warning time. By the time the firefighters wearing modern personal protective equipment sense the temperature increase, they will be in a very dangerous situation. Never rely on sensing sudden heat buildup.

One of the best ways to detect heat is through thermal imaging cameras. Where available, they should be a standard part of every size-up and internal operation. Another simple way of checking temperature is to place a small burst of water on a very narrow pattern into the overhead layer. If the water returns to the ground without any hissing, it is likely that the ceiling temperature is below 212°F (100°C) in that area. If, on the other hand, the water does not come down and a hissing sound is heard, the temperature is higher than 212°F (100°C). You can also carefully feel with a gloved hand to sense heat buildup. If you don’t feel excessive heat through your glove, slip the bottom of your glove over your palm to expose your skin and cautiously lift your hand overhead to feel the heat layer.

Flame

There is a tendency to focus on any visible flame on arrival. There is nothing inherently wrong with this if it does not lead to a loss of situational awareness. Unless the structure is totally involved, it is still critical to read all the fire behavior indicators to get a complete picture on the current stage of fire development as well as the likely path of fire extension.

Volume and Location

Incidents in which flames are externally visible on arrival obviously make it easier to determine the seat of the fire and the likely direction of spread. It is important to look for signs of multiple seats of fire and to realize that visible flame may have spread some distance from the original source.

Autoignition

Smoke autoigniting outside an opening indicates that the internal conditions are above the autoignition temperature (AIT) and too rich to support full flaming combustion inside the compartment (photo 8). When the superheated rich smoke leaves the compartment, it can dilute down from a mixture within the flammable range. If it does not cool down to below the AIT during this process, the fuel content can ignite spontaneously. When you encounter these conditions, it is critical to realize that increasing the air available to the room may result in a sudden and possibly violent increase in fire intensity (backdraft). Under these conditions, close doors or windows until hoselines are in place. Careful application of water into the space before ventilation may reduce the temperature of the smoke to below the AIT and decrease the likelihood of sudden intensification.

(8) Smoke (almost white) emerges from the opening. It is hot enough to ignite, but it is too rich. It is only when the outer edge dilutes down to the upper flammable mixture that the gases can autoignite.

Pockets of Flame Forming in the Smoke Layer (Ghosting)

If internal crews begin to see pockets of flame forming above the neutral plane, this is an indicator that the unburned fuel in the smoke layer is approaching the AIT. Cool the smoke, and consider withdrawal. Better still, don’t wait to see this: Cool the gases before entry and during internal operations (photos 9, 10).

(9) Pockets of flame forming in the smoke layer.

(10) Pockets of flame forming in the smoke layer.

Rollover

Once the accumulated unburned fuel begins to ignite, it is common for the flames to roll across the ceiling, resulting in a rapid increase in radiative heat. This could lead to flashover or fire gas ignition. The application of water in the ceiling space may stop or delay the progression of the rollover. If it is not possible to place water on the burning surfaces to slow the heat-release rate, the crew should retreat to a point of safety.

Color

Traditional teaching tells us that the color of the flame will give an indication of the product that is burning. This is true in situations where a single product is burning, but it is important to realize that the same product can burn with different color flames, depending on the combustion process.

For example, liquefied petroleum gas (LPG) that is premixed with air will produce a blue flame (because of the presence of carbon dioxide). If the fuel and air are mixed by the process of diffusion, the flame will be yellow because of the presence of carbon particles from a less efficient combustion process. LPG burning in an oxygen-deficient or fuel-rich environment can produce a red flame.

Another example is the combustion of particleboard in a compartment. When the air supply is good, it will burn with a yellow flame. If the oxygen concentration is reduced, the flame becomes reddish orange. In a compartment fire, yellow flames generally indicate a reasonable air supply. As the combustion process becomes less efficient (less oxygen), the flames start to turn orange and then red (photo 11).

(11) The ignition of a smoke layer a few seconds after a ventilation-controlled fire was ventilated by way of the back door. Note the reddish color and lazy flame over the instructor’s head.

The shape or form of the flame can also indicate the type of combustion occurring. The reddish orange flames that result from the rich combustion are often turbulent with a short-wave form. The ignition of accumulated pyrolysis products produces a very light-yellow flame, sometimes almost clear. Amazingly in this case, the wave form is larger, and the flames will move downward, seeking the higher oxygen concentration. As with all the indicators in the SAHF assessment, it is important to observe the initial flame color and then note any changes.

Reading the fire is like learning a language. Every fire is “speaking” to us through the fire behavior indicators. Sometimes the indicators are so clear that the fire is shouting at us! But if we don’t understand the language, it does not matter how loud the message is. Sometimes the fire is talking softly; even if we understand the language, we must pay close attention, or we will miss the message. Sometimes the fire tells lies. It deceives us by concealing critical information and telling only part of the story. So, not only must we know the language of fire, but we must also be aware that it will not always tell us everything unless we keep seeking input and reading between the lines!

The best we can do is to base those decisions on our knowledge of building construction and visible fire behavior indicators at each stage of the incident. There are no easy answers; but as scientific research enlightens our knowledge of fire behavior, we must be prepared to challenge our traditional thinking and to open our minds to new possibilities.

References

1. Raffel, Shan. “Reading the Fire.” (2002) Fire Australia Journal, pp. 11-13.

2. Ed Hartin in 3D Fire Fighting, Training, Techniques and Tactics with Paul Grimwood, John McDonough, Shan Raffel. Stillwater, Okla: Fire Protection Publications, 2005.

3. Bengtsson, (2001) Enclosure Fires, Swedish Rescue Services Agency, 115.

4. McBride, Peter. 2015. Smoke/Air track and relationship to flow path terminology. [interv.] Shan Raffel. 22 October 2015.

SHAN RAFFEL, AFSM EngTech CFIFireE, Churchill Fellow, is a 35-year veteran of the fire service and has extensive international training experience. His pioneering research in Sweden and the United Kingdom in 1997 led to major training and tactical reforms in Australia and other countries. He was awarded a Churchill Fellowship to study tunnel firefighting and holds the title of “Companion Fellow of the Institution of Fire Engineers,” awarded for his service to fire engineering.