“FIREFIGHTERS IN THE CEILING”: A LOOK AT FIXED FIRE SEPPRESSION SYSTEMS AND AGENTS

The World After Halon

There are many misconceptions regarding the proposed phaseout of halons and the chemicals available as replacements. The fire service community is in an ideal position to help educate concerned halon owners, alleviate their fears, and assist them in selecting future methods for fire protection against special hazards.

BACKGROUND

Environmental impact. The use of halons. or haiogenated chlorofluorocarbons, as fire extinguishing agents has undergone a great deal of scrutiny since it was discovered that the agents adversely affect the environment. Halons have been blamed for everything from increased skin cancer rates to the extinction of certain former earthly cohabitants. The unfortunate reality is that halons have an ozone “kill” capacity 1 3 times greater than freon. They will never again be the popular “agent of choice” for special applications. Fire service personnel and officials should be aware of the change in halon s status so they can perform their work more efficiently and safely and inform and advise the community they serve.

Description. Halons. a family of gaseous extinguishing agents developed in the late 1940s, found wide acceptance because they protect important assets without directly harming them. Halon agents are odorless, colorless, electrically nonconductive. and noncorrosive: they also leaveno residue. Halon seemed to be the perfect agent, the “agent of choice,” for a burgeoning special hazards fire protection industry. In addition, the agent was considered “people safe”: People in the room of discharge would observe extinguishment of the fire and live to tell about it with no adverse effects.

Halon 1.301, used for total flooding applications, and Halon 121 1. a streaming agent that can be used in portable fireextinguishers, are the most commonlyused halon agents. Both “extinguish” fires in the same manner: Despite the presence of fuel, oxygen, and an ignition source (the so-called fire triangle), halons directly interrupt the chemical process a fire needs to continue to burn.

Uses Private individuals, small companies. corporations, research organizations, and military installations or other government agencies possessing an asset considered valuable enough to warrant special protection from fire might own a halon fire extinguishing system. The specific value might be the original or replacement cost of the equipment, the function performed by the asset, the stored information (or the cost of recreating the saved records), or the cost of the potential interruption of service Halon systems might protect vehicles. small compartments, equipment enclosures, computer rooms, telecommunication equipment rooms, or any other hazard that can be enclosed.

CHR0N010GY OF HALON-CONTROL MEASURES

In the 1980s, growing concern over the diminishing ozone layer led to a number of studies that identified certain groups of chemicals as contributors to this ozone loss. Recognizing that without cooperation, no single government could effectively regulate these chemicals, the United Nations Environmental Program (UNEP) called for a treaty to limit the production of suspected ozone-depleting chemicals. The treaty, named the Montreal Protocol after the host city, was finalized on September 16, 1987. Halon production was to be frozen at 1986 levels beginning in 1992. further research indicated the ozone problem was worsening.

- In 1990, the UNEP committee met in London and called for a 50-percent reduction in halon production in 1995 and a total phaseout by the end of the year 2000.

- In the United States, the federal government passed the Clean Air Act amendments. which follow the UNEP schedule but also provide for specific intermediate reductions in the manufacture of halon.

- In 1992, the UNEP committee proposed a significantly accelerated schedule for the phaseout of the new production of halon. New halon was not to be manufactured after January I. 1994.

- The Budget Reconciliation Act of 1990 established an excise tax on newly produced halon. which was increased by the National Energy Conservation Act of 1992. The tax on newly produced halon today is S i 4. AO per pound, compared with an initial cost of about S12 per pound.

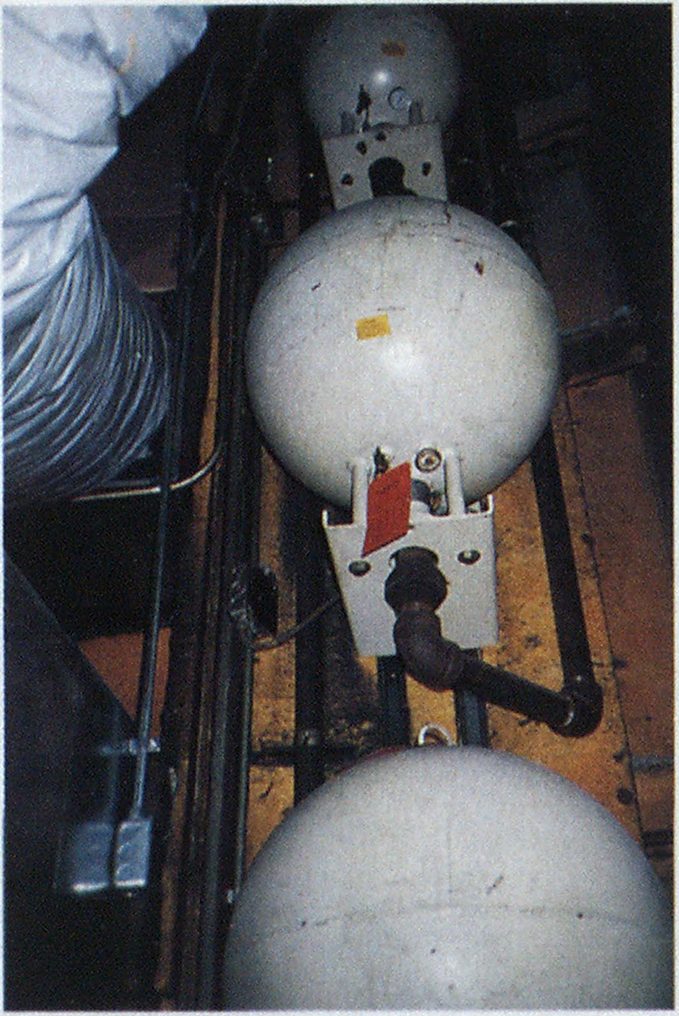

(Photo by author.)

![Replacement systems utilizing alternative agents (left) may have different physical space requirements. (Photo by author.) Rapid-response smoke detection (right) can be incorporated into alternative protection design approaches. [Graphic courtesy of IEI (North America) Inc.]](/content/dam/fe/print-articles/vol-147/issue-6/firefighters-in-the-ceiling-a-look-at-fixed-fire-seppression-systems/img-4.jpg)

FUTURE HALON USE

The expression “phaseout” of halon is not entirely accurate. I’nder the terms of the Montreal Protocol, new halon may be manufactured, even after 199-t. if it is deemed to be for “essential use.” Essential use designation in the I’nited Slates requires that a detailed application be submitted to the I S Environmental Protection Agency If the application is accepted, the EPA will nominate the use to the I NEP. which will evaluate the user’s application according to the following criteria.

- The use is necessary for human health and safety or critical for the functioning of society.

- There are no technically and economically feasible alternatives.

- All feasible actions have been taken to minimize emissions from the use

- The supply of halon from existing banks or recycled stocks is not sufficient to accommodate this need.

ALTERNATIVES

Through its Significant New Alternatives Policy (SNAP) program, the EPA categorizes proposed substitutes as acceptable or unacceptable, based on human health and safety and environmental impact concerns.

National Fire Protection Association (NFPA) 2001, Standard on Clean .Agent Fire extinguishing Systems, covers uses and limitations; system design (including components, agent storage and distribution. detection, actuation and control, specifications, plans, and approvals); discharge time; and inspection, maintenance, testing, and training for clean agent extinguishing systems for total Hooding applications.

A number of alternative agents are currently available. Agent selection for new systems should be based on the specific details of the hazard to be protected, such as whether the space is normally occupied. the cost of the original system installation. the cost of the agent at the time of system recharge, and the various properties and characteristics of the agent.

OTHER PROTECTION OPTIONS

Owners whose assets represent special hazards may want to consider alternative approaches to their fire detection needs in addition to the alternative agents current ly available. Such specialized or highly sensitive detection equipment would pro vide earlier notification of a fire, perhaps even before open flaming has started accelerate equipment and power shut down, if necessary; and accelerate local manual response.

Telecommunications facilities can use sensitive HCI. detectors, which are activated by the hydrochloric acid released from the insulation of conductors as temperature increases. Other facilities may opt for rapid smoke detection, such as iEI’s VESDA (Very Early Smoke Detection Apparatus) system or Fenwal’s HSSD (High Sensitivity Smoke Detection) system, as part of their special hazards fire protection program.

UNDERSTANDING POST-HALON TERMINOLOGY

Since degradation of the earth’s ozone layer is one of the primary concerns manifested in the Montreal Protocol, several methods for measuring an agent’s impact on the environment were developed. The ozone depletion potential (ODP) evaluates agents according to their impact on the ozone layer. The global warming potential (GWP) indicates the degree to which the product might otherwise contribute to global warming. The (AVP can be used to compare one product with another to assess the overall adverse environmental effect. One other comparison. an agent’s atmospheric lifetime (in years), is also used. It is an estimate of the length of time it takes the discharged agent to be fully absorbed by the atmosphere and to be no longer specifically detectable.

HALON ALTERNATIVES CURRENTLY AVAILABLE

A number of alternative agents are commercially available. Agent selection of or new systems should be based on the specific details of the hazard to be protected, whether the space is normally occupied, the cost of the original system installation, the cost of the agent at the time of system recharge, and the various properties and characteristics of the agent.

Total flooding agents addressed in the draft standard NFPA 2001, with pertinent information, are listed below:

A. Common name: PFC-410 Perfluorobutane Manufacturer: 3M ODP: 0 (AVI: 5

Atmos, life: “very long”

Other: Requires approximately 2.5 times as much agent by weight as Halon 1301

H. Common name: FM-100 Bromodifluoromethanc Manufacturer: Great fakes Chemical Corporation ODP: 1 l

GWP: Not provided

Atmos, life: Not provided

Other: Not for use in occupied areas

C. Common name: FE 241 Chlorotetrafluoroethane Manufacturer: Du Pont Chemicals ODP: 0.02

GWP: 0.10 Atmos, life: 7 years Other: Requires approximately two times as much agent by weight or liquid volume as Halon 1301

D. Common name: FE 25 Pentafluoroe thane Manufacturer: Du Pont Chemicals ODP: 0

GWP: .58

Atmos, life: 28 years Other: Requires approximately two to two and one-half times as much agent byweight or liquid volume as Halon 1301

E. Common name: FM 200 Heptafluoropropane Manufacturer: Great Lakes Chemical

Corporation ODP: 0 GWP: 0.7

Atmos, life: Not provided Other: Requires approximately two times as much agent as Halon 1301; HF by-products produced in greater amounts than for Halon 1301

F. Common name: FE 13 Trifluoromethane Manufacturer: Du Pont Chemicals ODP: 0

GWP: 5.7

Atmos, life: Not provided

Other: Requires approximately two

times as much agent by weight and approximately four times as much agent by liquid volume as Halon 1301

G. Common name: Inergen

Ki-541

Manufacturer: Distribution rights held by Ansul

ODP: 0 j

GWP: Approaching 0. except for trace of C02

Atmos, life: “zero”; agent is a blend of norniitlly occurring atmospheric gases

Other: Product stored as a gas; requires approximately 20 times as much storage i volume as Halon 1301

H. Common name: NAF S-III

HCFC 594

Manufacturer: North American Fire Guardian Technology, Inc.

ODP: 0.044

GW P: 0.01

Atmos, life: 7 years

Other: Elevated decomposition prodv ucts compared with Halon 1301

I. Others:

- Carbon dioxide systems: Generally not for occupied areas.

- Dry chemical systems: Temporarily can obscure vision: toxicology for total flcxxling applications unknown.

- Water: Potentially damaging to protected equipment: electrically conductive.

Note: A new NFPA standard on water-misting systems is currently being developed.

The ideal agent, of course, would have the lowest possible ODP, GW P. and atmospheric lifetime figures: have toxicological properties that present little or no health risk to hazard occupants and emergency service personnel; be inexpensive to install, maintain, and recharge; consume little valuable building space; and have superior extinguishing capabilities for all types of fires. In real life, however, the purchaser must forgo one or more characteristics of the ideal agent when selecting from among the alternative agents currently available, since none of these replacement agents are true “drop-in” replacements for Halon 1301.

COURSES OF ACTION

Fire departments should be aware of and disseminate to halon users in their jurisdictions the following information:

- There is no regulation requiring owners to dispose of. recycle, or otherwise turn in the halon they own. Ilie writing is on the wall, however, for systems that have yet to be built. Clearly, halon will not be widely used in future systems.

- Owners interested in removing an existing halon system must handle the agent properly. Because no new halon agent is being manufactured, halon “banks” are being created to hold the existing agent until acceptable uses are found. Any (former) local halon distributor should be able to provide direction. In addition, the Halon Recycling Corporation (HRC), a volunteer, nonprofit organization. can assist in matching companies having excess halon with companies needing the agent for critical uses. The HRC can be contacted at (800) 258-1283 or (202) 223-6166. fax: (202) 223-5979.

- No currently available alternative agent can be considered a true “drop-in” replacement for Halon 1301 systems. W hile all of the alternative agents possess individual benefits, none can be said to use the same number of the same type and si/e of storage cylinders, the same discharge piping and nozzles, and the same designed discharge rates and concentrations. A fire protection design professional familiar with the proper application of each of the various alternative agents and the hazard involved should assist owners in selecting new or replacement systems.

THE FIRE DEPARTMENT

Fire departments should take the following actions to ensure that halon use and replacement within their jurisdictions will not present safety problems for the public or their personnel:

- Be aware of the specific locations protected by existing halon systems within your jurisdiction.

- Insist that owners have these systems properly inspected and maintained.

- Carefully check cylinder weight records during annual inspections so that any loss of agent does not go unnoticed.

- Stress to building owners and their representatives the importance of maintaining their systems.

- Inform special hazards owners of the changes pertaining to halon use and their options for replacing existing systems.

- Continue to learn about current developments regarding halon use: Regulations change; products are rapidly being developed and tested; and innovative, alternative approaches to special hazard fire protection are just around the corner.