Rural Hitch

FEATURES

WATER SUPPLY

Once, most rural water supply operations suffered from two major deficiencies, deficiencies that resulted in property loss and, unfortunately, life loss as well:

- Insufficient flow and/or duration of flow.

- Lack of an orderly, safe, and reliable procedure for speedy implementation of supply lines and the ability to provide sufficient, uninterrupted water flow.

The first deficiency received much attention in the 1970s. The rural fire service redesigned its tankers, adding dump valves and high-flow venting (larger openings in tops of tankers). We purchased folding tanks and used large diameter hose for relay operations.

The second deficiency in water supply operations can be dealt with by developing an effective deployment system for folding tanks and large diameter hoses. The deployment system developed by the Levant, ME, Volunteer Fire Department stresses simplicity, reliability, safety, and speed of initiation. The importance of the system will be evident to any firefighter who has witnessed a fire spread while a folding tank was being set up, or seen an interior line go limp while a pump operator attempted to switch his water supply from the apparatus’ tank to a draft operation. One need witness once the near tragedy of an exhausted firefighter exiting a fire building into the path of maneuvering water tankers to know that there must be a better way.

Our better way is to bring the hydrant pack or hydrant hitch to the rural situation—a rural hitch. We find it especially helpful because the same simple procedure is used for every fire.

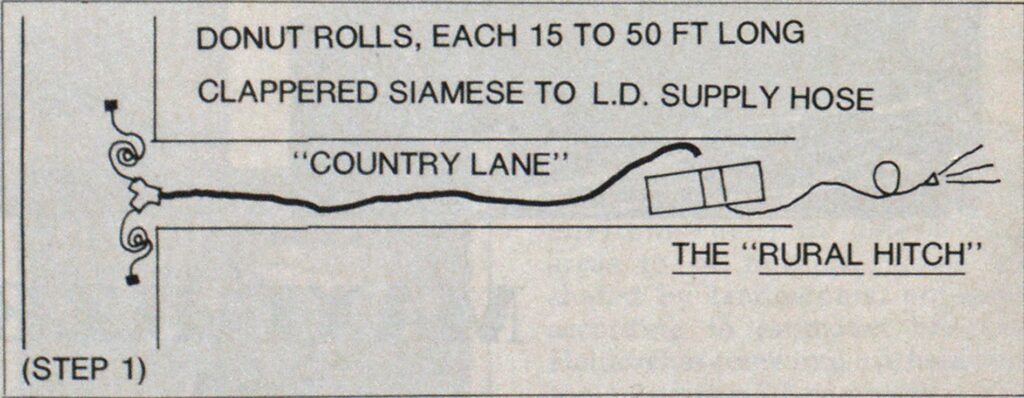

A clappered Siamese is dropped at the street, much the same as an urban pumper would wrap a hydrant and proceed to the fire (forward lay). The Siamese, with its pre-attached inlet hoses, becomes the focal point of all further water supply evolutions: tanker shuttle (with or without folding tank), hose relay, or portable pumps.

Step 1. The first arriving engine lays a supply line from a good turnaround point. This is done for any situation that will not obviously be controlled with 500 to 1,000 gallons of water from the pumper’s tank. This supply line should be of large diameter (four inches or larger), but smaller lines can be used. However, these smaller lines will have the same restricted flow that results with small diameter hydrant supply lines. This first arriving pumper then begins its normal initial attack using its tank water. Note that the 2 ½ x 4-inch clappered Siamese may be carried on either the first or second arriving vehicle.

Step 2. The second arriving pumper or tanker provides an immediate water supply by connecting to one of the inlet sides of the Siamese and pumping off. Onehundred psi discharge pressure here will supply at least 500 gpm to the attack pumper via the Siamese. The 21/2or 3-inch supply hose leading into the Siamese should not be over 50 feet, and the 4-inch hose coming from the Siamese to supply the attack pumper should not be over 1,000 feet. Larger hose diameters or shorter lengths will reduce the engine pressure needed. The attack pumper now switches to this water supply being provided by the second pumper. If flow rate permits, the attack pumper can even refill its tank. Note the orderly transition afforded by this system without depending on a priming maneuver.

Subsequent shuttle apparatus will connect the available inlet hose of the Siamese to its pump discharge, engage the pump with its engine at idle and tank circulation on. This third unit will pump in when either the prior unit has emptied its water supply or a greater flow rate is ordered from the attack scene. Such “waiting one’s turn” brings order to the evolution and provides a natural spacing of tankers in the shuttle, while supplying positive pressure to the attack engine at all times.

Step 3. If a folding tank operation is desired, it is set out at the rural hitch. Water supply to the fire incident and attack pumper is uninterrupted while the proper spot for the folding tank is selected, tank set, filled, and an engine set up to draft from it. The water supply to the fire scene is smoothly added in just as any arriving unit would be—via the Siamese (rural hitch). Note that the water supply activity (backing and dumping tankers, etc.) is thus kept safely away from the firefighting activities. Also, we do not depend at any point on the attack pumper’s ability to switch speedily from its tank to a draft hose. Further, the attack engine can be positioned to its best size up and attack purpose—there is no need to leave room at its side for a folding tank.

The rural hitch is assembled from a clappered Siamese and donut rolls of appropriate size hose (above).

The rural hitch is preferably loaded as a finish in the hose bed, or at the rear step, to facilitate its rapid deployment (as with a hydrant hitch).

A suction relief valve and intake control valve, such as shown at left, are important safety devices for all situations wherein the attack pumper will receive water supply from a pump. The device shown here combines control valve and suction pressure relief in a single unit. A short (approximately 6-foot) length of large diameter hose has been attached to the outlet of the dump valve so as to divert surges away from the pump operator.

This procedure will be the same for any rural fire. We can switch to a portable pump or pumper relay supply at any point and still leave the tanker or folding tank and pumper on the other inlet of the Siamese at all times (for reliability). Sometimes the supply line will be only 100 to 200 feet long, but not shorter for safety reasons of backing tankers, etc. The procedure is flexible enough to fit all situations. It encourages the laying of a supply line at all working fires, even when the pond is at the fire.

Table I below shows the tanker discharge (TD) pressure of the above diagram in psi. The tanker is expected to provide a minimum 500 gpm fire flow to the attack engine. Ten psi residual pressure is allowed at the suction of attack engine and friction loss of Siamese is approximated at that of a 2 1/2-inch swing check (NFPA 13, Table 7-4.2).

Five-hundred gpm at discharge pressures shown should be attainable via a common PTO type pump with 350 gpm minimum rating (at 150 psi), provided that the suction piping is of adequate size, usually at least 4-inch (500 gpm can often be attained from these pumps at net pressures of not over 100 psi).

NOTE: Any rural water supply method should be designed to achieve at least 500 gpm for “blitz attack’’ option.

* Pressure is less than 25 psi, and not practical.

NOTE: There are severe restrictions provided by 2 1/2″ and 3″ hose at these low flow rates.