BY JONATHAN HALL

Stretching hoselines should be a bread-and-butter task for every fire department. Proper deployment of the initial attack line is often the pivotal operation that makes or breaks the firefight. Every engine company should strive to correctly position its line and take the necessary steps to ensure success. Although multiple companies often are operating on the fireground, it is critical that engine companies make every effort to be as self-sufficient as possible. Autonomy allows each engine company to easily and rapidly advance its attack lines.

Evolving into a self-sufficient engine necessitates considering the apparatus specs; the hoselines and the nozzles; and department staffing and standard operating procedures (SOPs), which play a critical role in engine company operations. However, training and deployment on the fireground are key to becoming a reputable engine company.

(1) Photos by author.

Hoselines, Hoseloads, and Hosebeds

Self-sufficiency begins with a systematic look at hose loads. Evaluate your response district and staffing levels to tailor the apparatus and the hose loads to your needs. Standardization is important, but you may need to modify certain apparatus to accommodate the building types and occupancies in your district.

In developing specifications for new engines, keep the main mission in mind: efficient hoseline deployment to rapidly get water on the fire. Too many apparatus have their hosebeds positioned excessively high, making stretching hoselines difficult and increasing the risk of injury. If feasible, keep all hoselines, crosslays, and rear beds as low as possible. Specify water tanks that are “L” shaped, where the forward portion of the tank, ahead of the hosebed, is elevated. The rest of the tank is under the hosebed floor. This allows for a lower hosebed floor.1

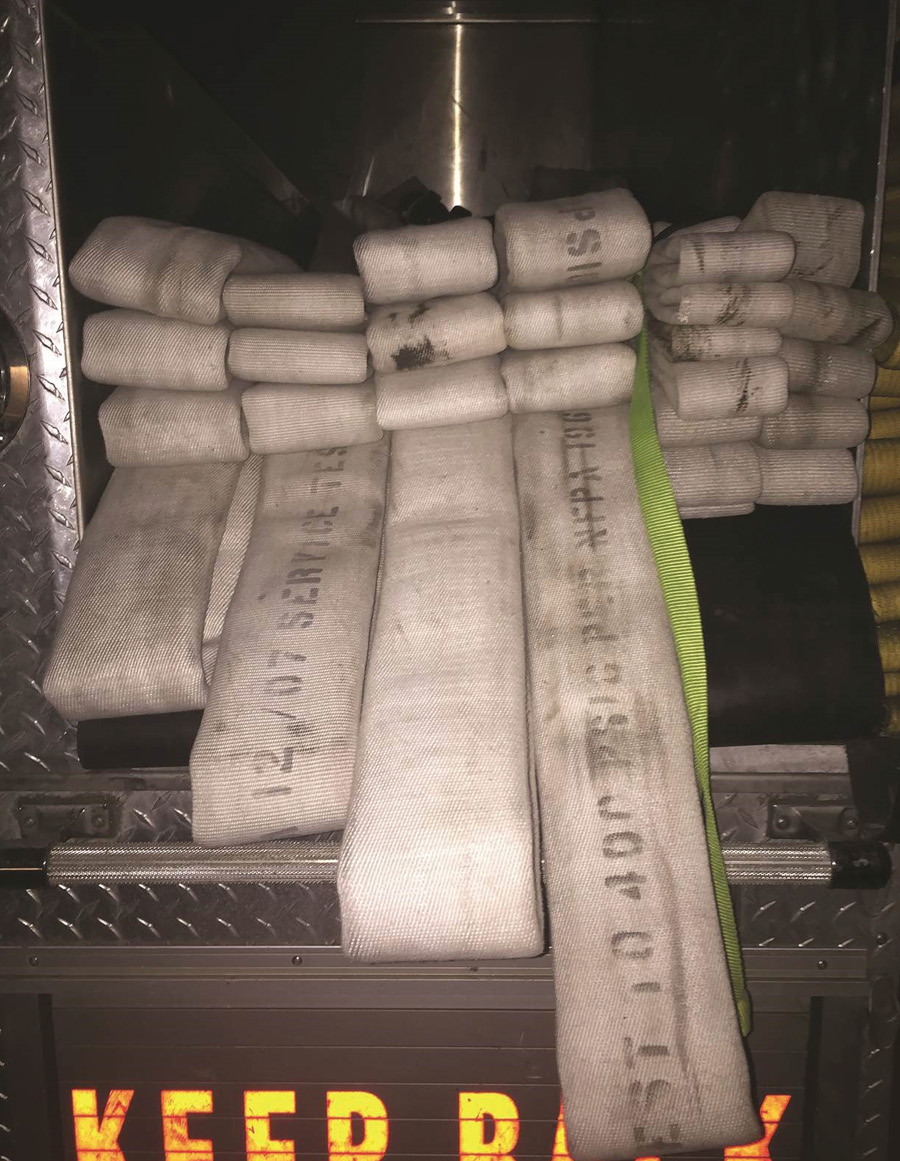

Keeping hoselines low helps facilitate quick and easy deployment (photo 1).

If an apparatus has a high hosebed or crosslay configuration, adopt safe practices to reduce the chances of injury when stretching hoselines. Consider having the driver/operator, who is not wearing full personal protective equipment (PPE), climb up on the tailboard or running board to assist firefighters with loading hose onto their shoulders. This method greatly minimizes the possibility of a fall, as it eliminates firefighters with decreased mobility because of full PPE and self-contained breathing apparatus from climbing on the apparatus.

Engine companies should be equipped with a versatile complement of hoselines to combat the diverse array of setbacks, occupancies, building layouts, and fire conditions they may face. At a minimum, engines should have small-diameter attack lines such as 1¾-inch, medium-diameter 2½-inch attack lines, and some variety of supply lines. The exact number of each diameter carried will be specific to the district and the apparatus. Keep sound hydraulic principles in mind when specifying hoseline length. The maximum viable length of 1¾-inch hose depends on several variables: the desired flow in gallons per minute (gpm); the nozzle’s operating pressure; and the friction loss in the specific brand, model, and age of hose. If possible, always fill out longer stretches with medium-diameter hoseline.

Analyze your response district to determine which hose loads will work best for your area. If the department chooses to use preconnected handlines, they should be loaded in such a way that a single member can easily deploy them. Two common hose loads that satisfy this requirement are the triple lay and the minuteman.

Triple Lay

One member grabbing the nozzle and a bight of hose can easily stretch the triple lay, but this load has several situational weaknesses. When dealing with short setbacks, one-third of its overall length must be stretched before it fully clears the bed. When an occupancy has fences at the sidewalk in the front yard, negotiating tight turns into a fenced-in yard is difficult for a single member to manage since he does not carry a significant length of hose on his shoulder.

Minuteman

The minuteman load can be arranged so that one member can effortlessly deploy the entire preconnected length (photo 2). You can easily maneuver the minuteman through fences since a member carries a stack of hose on his shoulder around any obstacles to the drop point. The same member can directionally deploy the remaining length of hose in the bed by grabbing a preset loop. Further, you can develop proficiencies to allow the minuteman to smoothly adjust for a short setback. Regardless of which preconnected load you select, thoroughly evaluate the decision to ensure the implemented option works best for you.

(2)

(3)

For longer stretches, you should arrange static beds such that, with the fewest members possible, you can easily deploy the hoseline a significant distance. The key to long stretches is transporting stacks of hose on your shoulder (photo 3). Physically carrying the hoseline allows you to smoothly negotiate around any potential snag points or obstacles. If you stretch by dragging hose, you will need numerous personnel to manage every corner you encounter. Without adequate personnel at these friction points, the line will get snagged and hose advancement will cease. By using shoulder stacks, the line pays off as members advance to their destination, eliminating the need to tie up valuable personnel to manage the friction points. Members must bring enough line to ensure they have at least a 50-foot working length once they reach their objective.

Nozzles

When selecting nozzles, maintain a delicate balance between gpm and acceptable nozzle reaction (NR). Today’s fires produce higher heat release rates than those of yesteryear and require more gpm to extinguish.2 Yet, most fire departments are responding with fewer personnel. The key is to select nozzles that flow the required gpm with nozzle reactions that are manageable by one or two firefighters.

On the fireground, the rate of water application will depend on the diameter of the hoseline you select during the initial size-up. National Fire Protection Association (NFPA) 1710, Standard for the Organization and Deployment of Fire Suppression Operations, Emergency Medical Operations, and Special Operations to the Public by Career Fire Departments (2016 ed.), states that departments should establish “an effective water flow application rate of 300 gpm from two handlines, each of which has a minimum flow of 100 gpm.”3 By deductive reasoning, the first attack line should be flowing a minimum of 150 gpm to meet the 300 gpm standard once the backup line is in operation. Even if the backup line is of a larger diameter, fires are requiring higher minimum flow rates. As a reminder, the backup line should always be the same diameter, if not larger, than the initial attack line. With the NFPA standard in mind, departments should select 1½-inch nozzles that flow a minimum of 150 gpm while allowing for easy operation. Nozzles designed for 1½-inch and 1¾-inch hoselines have 1½-inch female threads. Manufacturers refer to them as 1½-inch nozzles. Medium-diameter handlines, like the 2½-inch, should have flows closer to 250 to 325 gpm.

Nozzle Reaction

Nozzle reaction is based on Newton’s third law of motion that states for every action there is an equal and opposite reaction. The volume of water leaving the nozzle and the pressure at which the water is leaving determine the nozzle’s reactionary force.

Handlines must be manageable by today’s minimally staffed engine companies. Paul Grimwood conducted a 1990 study of handline streams used by the London Fire Brigade. His goal was to evaluate the “maximum flow capabilities for a hoseline that could be effectively directed and safely handled whilst advancing and working inside a fire-involved structure.”4 Grimwood determined that one firefighter could handle a maximum nozzle reaction of 60 pounds (lbs.); two firefighters, 75 lbs.; and three firefighters, 95 lbs.

The following formula is used to calculate nozzle reaction for fog nozzles:

NR = 0.0505Q√NP , where NR = nozzle reaction in lbs., Q = gallons per minute, and NP = nozzle pressure.

The following formula is used to calculate nozzle reaction for smooth bore nozzles:

NR = 1.57D2 NP, where NR = nozzle reaction in lbs., D = diameter of the smooth bore tip, and NP = nozzle pressure.

An engine crew of four personnel yields three members deploying the handline on scene as the driver/operator is routinely assigned to the pump panel. One firefighter is often assigned to feeding hoseline at the door, leaving a firefighter and an officer to operate near the nozzle. If staffing is reduced to three personnel, the very real possibility exists that a single firefighter may be operating the nozzle without an immediate backup person. Therefore, departments should select nozzles that produce a nozzle reaction as close to 60 lbs. or less, if possible.

The two major tenets have now been defined: a nozzle that flows a minimum of 150 gpm with a nozzle reaction as near to 60 lbs. as possible and a fog nozzle requiring an operating pressure of 100 lbs. per square inch (psi) and flowing 150 gpm would produce a nozzle reaction of approximately 76 lbs. To reduce nozzle reaction to more manageable levels requires reducing either the gpm or the nozzle’s operating pressure. Since reducing gpm is not an option, using low-pressure fog or smooth bore nozzles becomes the only practical solution.

Nozzle reactions for common 1½-inch nozzles are as follows:

- 50-psi fog nozzle flowing 150 gpm = 54 lbs. NR.

- 75 psi fog nozzle flowing 150 gpm = 66 lbs. NR.

- 7⁄8-inch smooth bore tip @ 50 psi flowing 161 gpm = 60 lbs. NR.

- 15⁄16-inch smooth bore tip @ 50 psi flowing 185 gpm = 69 lbs. NR.

All of the 1½-inch nozzles listed above produce adequate flows with nozzle reactions that are at, below, or just slightly above those manageable by one firefighter. With proper training and techniques, a single firefighter should be able to manage all of the nozzles. In photo 4, a single firefighter employs the lock-off or Comella method to safely manage the nozzle reaction of a 7⁄8-inch smooth bore nozzle.

(4)

When deploying medium-diameter hoselines, strongly consider pairing two engine companies to stretch and operate the initial attack line. Always give priority to getting the first line in operation before stretching additional lines. Nozzles for 2½-inch hoselines produce significantly more nozzle reaction, thus requiring more personnel to operate them safely and effectively.

Nozzle reactions for common 2½-inch hoseline nozzles are as follows:

- 100-psi fog nozzle flowing 250 gpm = 126 lbs. NR.

- 11⁄8-inch smooth bore tip @ 50 psi flowing 266 gpm = 99 lbs. NR.

- 13⁄16-inch smooth bore tip @ 50 psi flowing 296 gpm = 111 lbs. NR.

- 1¼-inch smooth bore tip @ 50 psi flowing 328 gpm = 123 lbs. NR.

Just as with the 1½-inch nozzles, through proper training and techniques, one or two members can effectively deploy a 2½-inch handline with higher nozzle reactions. The key is to select high-flow, low-pressure nozzles. Departments must implement nozzles that work with their staffing levels while still producing the required gpm to combat today’s fire environment.

Riding Assignments/Fireground Roles

For engine companies to operate efficiently on scene, they must have a plan. The plan needs to be clearly conveyed, whether through departmental SOPs, established riding assignments, or the company officer giving orders on scene. To perform effectively, members must know their roles and what is expected of them. Plans help ensure vital tasks are performed and aid in member accountability. As always, the company officer or incident commander can alter the plan at any time.

Staffing levels vary significantly from department to department. Unfortunately, the common trend in the fire service involves accomplishing a greater quantity of tasks with fewer personnel. Many departments are responding with four or fewer personnel on an engine company.

A four-person engine company results in one member at the pump panel and three “operational” firefighters. The apparatus operator is responsible for navigating safely to the scene, positioning apparatus based on the officer’s size-up, and delivering water at the correct pressure through the selected hoselines. The company officer is responsible for sizing up the scene including doing a 360°, selecting the appropriate size hoseline, and determining the correct position of the hose stream. On the initial attack line, the backup person will likely be the officer. One firefighter will be assigned the nozzle. The nozzle firefighter is responsible for deploying the appropriate hoseline to the point of entry determined by the officer and correctly applying the hose stream. This leaves one firefighter available for assignment. Depending on the situation, this firefighter could be assigned to forcing the door, assisting with the hoseline stretch, or obtaining a positive water supply. Remember the importance of getting tank water on the fire! Do not delay the initial fire knockdown simply to get a water supply. If needed, the apparatus operator can often complete a water supply to a hydrant. No matter what the initial assignment, this firefighter will end up being the door position, feeding hoseline at or near the door to ease the advancement of the nozzle team (photo 5).

(5)

With a three-person engine company, members are forced to multitask even more. The apparatus operator’s initial tasks remain the same. After the attack line is charged, the operator may have to obtain a water supply or help feed hose at the door. The company officer is still responsible for the size-up and determining the initial course of action. In addition, the officer may have to perform forcible entry. The single firefighter is responsible for stretching the selected attack line and properly operating the hose stream. The officer will undoubtedly have to move around more in the structure to pull line and manage kinks to back up the nozzle firefighter. Accountability between the nozzle firefighter and officer is maintained through contact with the hoseline.

No matter what the staffing levels are in your department, you must have a plan. If members know their roles on the fireground, accountability is maintained and the operation runs smoothly.

Sizing Up the Stretch

An engine company size-up encompasses many critical details such as access, setbacks, building height and size, occupancy type, fire/smoke conditions, routes of fire travel, exposures, and potential victim locations. All of these determine the initial actions, including apparatus positioning, offensive/defensive operations, requesting additional resources, the initial attack line’s diameter, the hoseline length, the point of entry or stream application, and the need for an immediate water supply based on the engine’s onboard tank size. It is vital that the company officer attempt to conduct a 360° size-up before committing to his initial plan. Sometimes because of the size or configuration of the structure, an immediate 360° may not be feasible. If the 360° is not completed, it must be communicated and a later-arriving company should be assigned the task. The company officer must rapidly analyze all the components of his size-up, formulate a plan, and clearly communicate that plan to operating members.

The primary goal should be to get a hoseline between the fire and any potential victims. The company officer should determine the best point of entry for the attack line to protect egress as well as extinguish the fire. Rapid application of tank water significantly reduces fire growth and spread, making it safer for victims and firefighters. If victims are not present, place the line to protect the most significant internal and external exposures. In addition, if entry is delayed because of forcible entry challenges or an arduous stretch, perform a transitional attack to reduce the fire’s energy until you can make entry. If conditions warrant, quick water application from the deck gun may halt fire advancement and protect exposures.

If the situation involves a fire in a commercial occupancy after hours, strongly consider obtaining a water supply prior to attempting entry. Often, these fires go unnoticed for a significant time. The delay in notification coupled with a well-sealed building could result in a ventilation-Iimited fire. When entry is made, the sudden inrush of oxygen may rapidly intensify the fire. The resulting fire growth could easily overwhelm the suppression capabilities of tank water. In these circumstances, you should immediately secure a positive water supply. Order the positioning of charged 2½-inch handlines and master stream devices prior to opening up the structure.

The company officer must call for the appropriate diameter hoseline to combat not only the fire conditions present but also the fire potential based on the occupancy’s fuel load. Select a flow of sufficient quantity to achieve fire knockdown within 30 seconds of stream application. Remember, the 1¾-inch attack line may be your go-to line, but it will not produce sufficient gpm for every fire! The officer should ensure the correct amount of hose is stretched to reach the objective. Take time to conduct a thorough size-up to ensure the operation starts off correctly. Reflect on the old adage, “As the first line goes, so goes the fire.”

Hoseline Deployment and Working Length

Members must train and be proficient at stretching the various hoselines they have on the rig. Rapid deployment of attack lines allows for the swift application of the required gpm. Members must strive to deploy lines in such a way that a single self-sufficient engine company can easily advance the line to the seat of the fire. Taking a few seconds to properly stretch the line shaves time off your push into the structure and makes the job easier.

As the line is brought to the selected door or drop point, the nozzle person should have the nozzle and the 50-foot coupling. This 50 feet of hose is considered the “working length” and helps guarantee enough line to reach the fire (photo 6). A 50-foot section plus the reach of the fire stream is often sufficient for most small single-family dwellings and individual apartments. The nozzle firefighter should bring the 50-foot coupling up any stairs leading to the front door to prevent the coupling from getting caught on the stairs during advance.

(6)

Members should flake the hoseline perpendicular to the entryway. Stretching perpendicularly allows the door person to easily feed line straight into the structure and minimizes the friction points at the corners of the door. If the hoseline is stretched parallel to the structure, the door firefighter has to fight the line from side to side around the edges of the door frame.

You can call for water once the nozzle firefighter is in position and the line is flaked out. Kneeling on the coupling and nozzle prevents them from moving as the line is charged. Set yourself up for success before charging the line! Mask up, bleed the line, check your pattern, and ensure an adequate flow by evaluating the hose stream’s reach prior to entering the structure.

All these seemingly small elements pay great dividends on the fireground. Critically evaluate the components of the system to support the construction of a truly self-sufficient engine company. Members must become proficient with equipment and procedures through continual company drills. As always, take time in training to make time on the fireground!

References

JONATHAN HALL is a captain with the Saint Paul (MN) Fire Department and has more than 17 years of fire service experience. He was a training safety officer with the Township Fire Department in Eau Claire, Wisconsin, and has presented at FDIC International.