BY DAVE CASEY

The use of shipping containers for live fire training at fixed sites or as mobile units has become very popular in North America over the past decade. Much of the training has value to participating personnel, but there are some concerns about direct or indirect dangers to the firefighters being trained and to the trainers. Concerns include structural and construction issues; immediate and longer-term safety and health concerns; fire behavior differences; and compliance with National Fire Protection Association (NFPA) standards 1402, Guide to Building Fire Service Training Centers, and 1403, Standard on Live Fire Training Evolutions (interior attack mobile fire props are now included in NFPA 1403). You can take steps to mitigate those concerns and to improve the value and safety of the experience.

Structural and Construction Issues

Shipping containers, also known as intermodal containers, conex boxes (Container Express), or more officially International Standards Organization (ISO) containers, are designed to be extremely strong; be stackable; be uniform in size and design; protect the contents from theft; and be easy to load, unload, and transport via truck, rail, or ship. The shipping container is an American invention and gained popularity through U.S. military use, with most now built in China. Shipping containers reduce the cost of loading freight by more than 90 percent, which reduces the final costs to consumers of most manufactured items.1

The first consideration in using containers for live fire training is to keep in mind that shipping containers were not designed or built for live fire training. That being said, with proper precautions and planning, you can use them to conduct a good training exercise within certain parameters.

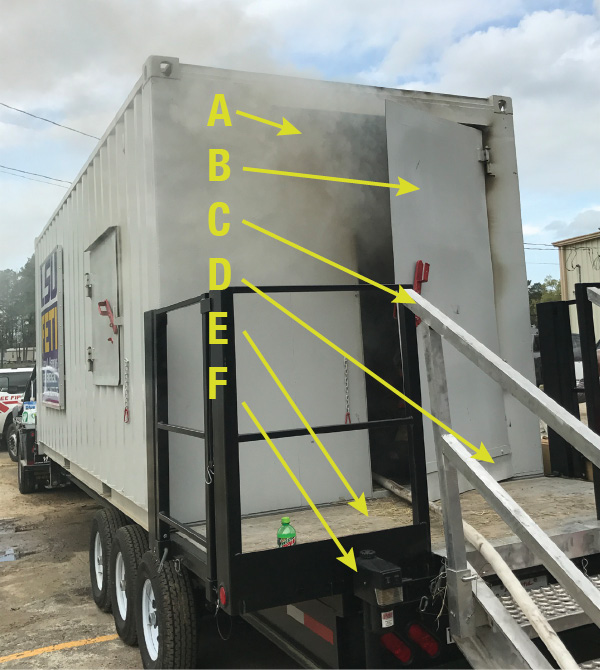

The standard “dry” shipping container (photo 1) has the exterior dimensions of 40 feet long, 8 feet high, and 8 feet wide. Interior dimensions are 37 feet 7 inches long, 7 feet 8 inches wide, and 7 feet 10 inches high. They weigh 5,820 pounds empty and are rated for more than a 61,000-pound cargo capacity.

(1) ISO 40-foot standard “dry” shipping container. (Photo by author.)

The majority of their strength is in the four corner posts (photo 1, A) and the top (photo 1, B) and bottom (photo 1, C) horizontal rails. In each corner, top and bottom, are the corner castings (photo 1, D) that lock the containers together stacked and horizontally when being shipped or to secure the container to a truck or railcar bed (rail can also be stacked). The corner posts are cast steel, and the top and bottom rails are welded to them. It is important to note that containers are designed to bear loads only on their corner posts.2 ISO containers are designed for stacking up to six high.3 When using multiple containers, use the locking mechanisms to stack the containers or to keep them together horizontally; they are readily available and reasonably inexpensive (photo 2).

The sides (photo 1, E) and front of the container (the doors are the “rear”) as well as the roof are corrigated steel panels that provide further strength and are most often made of Cor-Ten® steel, a weathering steel that is a fusion with copper and is designed to form a patina of fine oxide that protects the steel from rust and corrosion, reducing the need for painting to protect the metal. It has chromium, manganese, and nickel added.

(2) There are several types of locking devices to secure the containers vertically and horizontally (Photo by Dave Dorsette.)

The side panels on the containers contribute to the structural strength; cutting window opening, doors, or large openings into the containers will weaken their vertical strength. If stacking containers or making large openings, reinforce the openings with tubular or other load-bearing steel from the bottom to the top horizontal supports (photo 3). Consult a structural engineer for such major modifications.

(3) When there are openings or cuts through the corrugated metal sides, structural support needs to be added. Note the vertical and horizontal steel beams added where the side walls were opened in two containers to form a larger room. (Photo by Dave Dorsette.)

The standard container roof is not designed to be load bearing, but it is intended to support an evenly distributed weight of 441 pounds, so roughly two people. It is not designed to add additional roof props or other items without further support using the top rails or from below.4 On the corrugated roof area, this comes out to roughly 1.5 pounds per square foot. NFPA 1402:10.2.4 calls for a minimum live load capacity of 50 pounds per square foot. Remember, the corner posts are designed to carry the weight of up to five stacked containers, so additional roof decking or roof props need to be supported by the corner posts.

The rear two doors have multiple locking latching points and gaskets to prevent/reduce water and pest intrusion. Using the container doors during live fire training can be dangerous because of the latching mechanisms unless you disable them. Use a standard sized or preferably wider entry door cut into the container. NFPA 1402 points out the concern with salvaged actual entry doors becoming warped and binding and suggests using purpose-built doors (photo 4).

(4) Salvaged actual entry doors can warp from heat and bind. Consider purpose-built doors. Note the door handle has not yet been installed. (Photo by author.)

The floor has steel cross members fastened within the bottom rail. The floor decking is most often wood, a violation of NFPA 1403. Note that you should not place containers directly on the ground because of damage to the wood floor and cross members from the lack of air circulation and dampness from water under the container. You can use steel decking, but it will get very hot and buckle near the fire area. You can also use fire brick or nonrefractory pavers without mortar (NFPA 1402:10.4.2.3).

Following are some additional considerations for using shipping containers:

As mentioned above, do not use the standard two leaf rear doors with locking mechanisms on them as the primary entry/exit. Ensure adequate exiting by using standard size and operational doors (they can be heavy gauge metal with a frame) to provide multiple exit points. “Window” (shutter) openings should be low enough and wide enough for emergency bailout/egress and allow for easy push-to-open operation. Consider door “sweeps” to allow fire hose under a closed door (a piece of four- or five-inch large-diameter hose works well).

Put the containers at a slight grade with scuppers (cutouts) or drains for water runoff out of the containers. Pooled hot water will saturate personal protective equipment (PPE) knees and can cause burns and adds weight to the container. NFPA 1402: 10.2.3 recommends a grade of at least one-quarter inch per foot.

Make sure the containers are on a stable foundation. This is critical if you plan to stack units.

Pave or deck (with pavers, etc.) the area around the entry for safer evolutions. NFPA 1402:10.2.5 recommends paved areas for apparatus and lighter paved areas around the remainder. This will allow better footing for ladders and keep equipment from getting as dirty or muddy. NFPA 1402 further suggests adding curbs, poles, street signs, cabling to represent electric lines, and such to better replicate obstacles that you will encounter at real fire incidents.

Stacked containers can allow vertical fire spread after significant use and/or overly harsh fire conditions (photo 6).

(5) A vendor-modified container: A—rear doors removed; B—purpose-built door with easy-to-use latch; C—hand rail around “porch” and stairs (note this unit allows the stairs to be on either side or the back); D—hose sweep; E—trailer levelers; F—nonskid deck, safety tread on stairs. (Photo courtesy of JFB Enterprises.) (6) Heat/fire damage from fires in the container below this one. Note the steel floor cross-members under the wood decking. (Photo by author.)

There have been multiple reports of steam explosions occurring within the tubular steel structural members under high-heat conditions that have flung metal fragments. A long-time compartment fire behavior training (CFBT) instructor, Chief Ed Hartin of South Whidby Island, Washington, was present for such an occurrence: “… water (likely from rain or another environmental cause) entered the sealed square tube at the top of the container above the rear doors (likely through a small area of corrosion). Failure occurred during the process of burning in the container to remove any oils or residue from the construction process. A substantial fire was lit in the container and allowed to burn without intervention. Several minutes after the fire became fully developed, a loud hissing could be heard from the rear of the container as the water in the tube turned to steam and began to escape from the small opening that allowed water to enter. Pressure rose faster than the small opening could allow it to escape, and the square tube failed.”

Another such incident occurred in Switzerland after firefighters exited a prop. It is believed that rain had entered the tubular steel through a crack that sealed as the steel expanded, causing a violent rupture (photos 7 and 8).

(7) The upper channel over the container doors was blown apart from a steam explosion from a lack of venting the tubular steel. (Photos 7 and 8 courtesy of ZAR.) (8) Damage to the roof and the top of the doors. Note the top rail is not visible between the vertical posts.

Drill 1⁄8-inch vent holes on the bottom of the tubular steel rails to allow drainage and to release steam.

You can purchase shipping containers directly or through vendors that modify them for live fire training. They can use standard Class A fuels or gas-fired systems, both in accordance with NFPA 1402 and 1403.

There are ways to protect the container from fire damage and extend its life span.

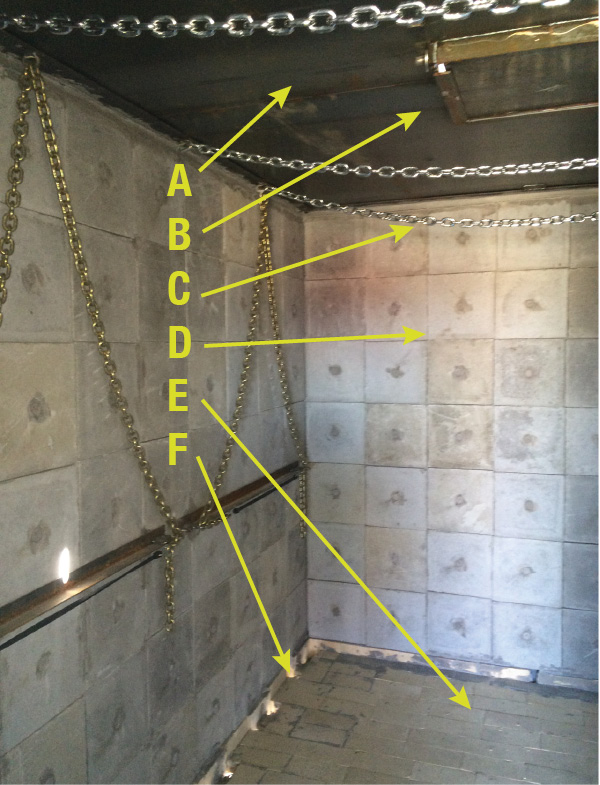

Thermal liners can be the same as for purpose-built concrete or steel props (photo 9) and are installed in many vendor-provided units and almost all gas-fired units. Because of the higher temperatures associated with Class A fuel-fired units, more heat resistive liners may be necessary. You can use an unlined container for the live fire training and locate it so it can be replaced more easily. You need to evaluate the cost benefit of thermal lining for Class A props, as the liners can easily be many times more expensive than the container itself.

Hearths or other protective measures will also extend the life span of the container. The University of Illinois Fire Service Institute and the Alabama Fire College use a standard dumpster with the lids removed and placed front down (photo 10) to form a hearth. The dumpster should be raised, using a poured concrete pad, patio pavers, bricks, or fire bricks. The dumpster hearth will reduce the direct flame impingement on the container ceiling and help keep the debris together.

(9) A—A “floating” metal ceiling below the container roof allows expansion without bucking; B—a roof vent, operable inside or outside; C—chains below the ceiling and on the walls with a rail to hold pallets or wood panels; D—a refractory tile thermal liner; E—fire brick pavers with no mortar; F—multiple scuppers. (Photo courtesy of JFB Enterprises.)

Purpose-built hearths can get the fuel off the floor and protect the ceiling and the container walls. By adding an open top steel bin or “drawer” below the hearth, staples, nails, and other debris can be contained that can be difficult to clean up and painful to kneel on (NFPA 1402:10.4.3; photo 11). The drawer slides out the side of the container to be dumped, or a container that is small enough to be carried can be used instead. Hearths can be built to be relocatable within the container or transferred to another container.

(10) A dumpster placed on its side can serve as a hearth. (Based on an illustration by author.)

(11) A hearth to protect the container roof and walls; the drawer below is to collect staples, nails, and debris that can be slid out to the left and dumped. (Photo by author.)

A sprinkler system—at least one vendor provides an exterior sprinkler system to protect the container. According to the manufacturer, the water-cooled system does not affect the fire behavior; however, it reduces the interior temperature caused by the heating of the container, providing a better environment for instructors resetting the prop between evolutions. The water spray protects the areas of the container most likely to be heat damaged, extending the life of the prop (photo 12).

(12) Exterior sprinklers protect the container and reduce interior temperatures between evolutions. (Photo courtesy of 3sFire.)

Mobile units can make entry/egress more difficult because of the trailer height. Wide stairs and even “porch landings” are good ideas (photo 5).

A wide open container interior reduces the realism of training exercises, as real structures will have walls, doorways, furniture, and other obstacles to a direct approach to a fire. NFPA 1403-compliant metal furnishings can be added at appropriate levels of training, and metal plate walls or walls of drywall and metal frames will add to the utility and realism.

Immediate and Longer-Term Safety and Health Concerns

Health hazards come from several sources. First is the obvious—heat and fire conditions. The smaller volume and lower ceiling height can lead to harsh conditions more quickly. Between evolutions, the containers tend to retain considerable heat.

Other concerns may not be as obvious. Dangers are present from contamination in the container from prior shipped products and/or fumigation, the paint on the container, and the fuel used for live fire training.

Shipping containers are routinely fumigated to kill insects. Contamination of the wood decking or other surfaces is possible, and an Australian study found residual chemicals in 74 of the 76 containers (97.4 percent) they checked, with eight percent exceeding the Australian Workplace Exposure Standards (WES) for one of the residual chemicals tested. However, airing out the containers dropped the levels almost immediately, with formaldehyde having a half-life of only 30 to 45 minutes. However, some of the fumigants last longer, such as hydrogen cyanide (half-life 0.9 years) and methyl bromide (half-life 0.3 to 1.6 years). Hydrogen cyanide and formaldehyde levels were reduced by approximately 80 percent after 24 to 36 hours.5 The primary concern should be the wood decking. Unless the container has been used for storage before acquisition by the fire service, it should be aired out already, but be cautious while removing wood decking. Clean the container interior before use.

Revinge is a large fire academy operated by the Swedish Civil Contingencies Agency. The instructors had a concern about their exposure to products off-gassing from the paint on the shipping containers they used during live fire training. They engaged the SP Technical Research Institute of Sweden to complete an analysis.6 Using paint samples from several containers used for live fire training at elevated temperatures, it determined what chemicals were released and at what amounts as the temperature increased. Several dangerous types of chemicals were found; of special interest was the possible release of isocyanates, which can occur if the paint contains polyurethane. It is already a known hazard that the thermal degradation of polyurethanes will release isocyanates. Isocyanates are a known health hazard through inhalation and through dermal contact. Health hazards include irritation of the skin, mucous membranes, eyes, nose, throat, and gastrointestinal tract; occupational asthma; chemical bronchitis; and pneumonitis. With occupational asthma, the respiratory tract becomes sensitized so that later, smaller exposures can trigger asthma attacks. Likewise, skin becomes more sensitive to the product. Some, but not all, isocyanates are associated with cancer. But the majority of health information is based on occupational or accidental exposure, not in the application of shipping containers or other painted metals exposed to high heat in fire training.

Based on the Swedish findings, it is difficult to quantify the specific level of hazard to a specific prop. Variables include the following:

- Air flow (fresh air into prop, smoke out).

- Temperature–the higher the temperature, the greater release. At just under 400°F, potentially harmful substances off-gas from the paint.

- Amount of paint present—a prop that has been in use and burned off much of the paint inside will release less product (unburned areas still will off-gas).

- Duration of exposure.

The training center that identified the problem now uses unpainted shipping containers made of Cor-Ten® steel.

Do not allow personnel in hot shipping containers without PPE and self-contained breathing apparatus (SCBA), and don’t allow personnel without protection to be in the immediate area of the containers during fire operations. Use positive-pressure ventilation (PPV) fans between evolutions to help clear the air (keep personnel from being downwind of the air discharge).

Ensure personnel decontaminate their PPE and themselves.

To reduce concerns, consider using nonpainted thermal liners in the burn areas, or use unpainted shipping containers. Cor-Ten® steel containers are common but are most often painted. You can buy containers new without paint or stripped.

In painted boxes, burn the paint off in the areas of concern in an unoccupied container.

The wood products used in the containers for fuel are most often wood pallets, primarily southern yellow pine wood (18.9 percent) and white oak (17.1 percent).7

Engineered wood products such as oriented strand board, plywood, particleboard, and fiberboard contain binders; earlier versions had glue that contained formaldehyde and other dangerous chemicals. The newer “green” products contain less formaldehyde and dangerous chemicals, but the water-based glues do not provide the fire behavior that earlier versions did.

The aforementioned decontamination procedures are necessary, as is the mandatory PPE/SCBA use. The smoke conditions can be harsher in the smaller environment than a larger structure, and the instructors will generally have longer time exposures during training than in actual emergencies.

Fire Behavior Differences

In the late 1980s, two Swedish firefighters died in a flashover, and the consensus was that there was a lack of training in the recognition of an impending flashover and of the fire dynamics and behavior in a “compartment” (room). A curriculum was developed with the use of the containers to train firefighters in a realistic environment about flashovers by actual, close-up observation under controlled conditions. CFBT was initiated. Over the years, the use of containers has expanded to include multicontainers, large compartments, and enhanced training programs.

A problem with many of the programs in use in North America and the United Kingdom is the focus on the single compartment fire behavior, door entry room-and-contents fires. British fire trainer and author Dr. Paul Grimwood warned that “single compartment systems are subject to limitations in that they can prepare the firefighter only for door entry procedure and one-room fires” and that the firefighters will not be prepared for the structural fire setting that involves multiple rooms and larger areas.8

In a shipping container, because of the lower ceiling, smaller room volume, and steel construction, the heat increases quickly and the fire acts differently than a structure fire. Most often, the container environment will remain more heated than a structure after the fire is knocked down.

Regarding the fuel loading, the materials used in the training fire differ almost totally from the contents of a structure. The training fire is propane or natural gas fueled only, or the fuel is NFPA 1403-compliant Class A natural wood products and hay, straw, or excelsior in a very reduced quantity in the container.

Vertical ventilation is very important and must be large enough to vent fire conditions that are harsher than expected. A very important concept n the Swedish manual9 is that venting should “fail to safety” in its design. Many such props have “deadman” levers to keep the vent closed, and releasing the handle opens the vent. Vents should be operable inside the container in a location determined through anticipated operation where it is readily accessible (preferably leaving an instructor or safety officer with the control) and from outside.

The takeaway is that your firefighters need to be prepared for real-world firefighting, and the evolutions in the containers need to be set up the way you need to operate at real-world incidents. Approaching the fire and directing streams in one manner for training fires but then expecting firefighters to do it differently “for real” weakens preparedness.

Compliance with NFPA 1402 and 1403

Even if your state or province hasn’t adopted NFPA 1403 and 1402, you must use them as you plan your prop. That lack of legislative adoption often does not prevent reference to the standards in safety citations and findings by government departments for workplace safety and will most assuredly be used in civil litigation occurring from injuries.

It seems fairly simple to place containers together and form a valuable training resource, but it is important to meet the local legal requirements as well as necessary safeguards. Per NFPA 1402:1.3, not all training props are required to meet the local building codes, but this needs to be verified and sometimes debated with that authority. Specific to shipping container use, NFPA 1402:7.5 states that a professional engineer should design the props so that the building code requirements are met for the vertical loads (if stacked), horizontal loads, and foundation requirements.

The need for two means of egress from every burn room is found in both NFPA 1402 (10.3) and 1403. Not stipulated in either is a recommendation that egress direct to the exterior or at least rapid egress be available.

Doors and window shutters are critical concerns and affect the realism of the evolutions. Doors should not have doorstops that are floor mounted that could catch or crimp hoselines (1402:10.6.1), and exterior doors and window shutters should open outward in the path of egress (1402:10.6.2). Doors need to allow for the rapid heating and cooling that you will encounter in live fire training and that can cause a door to bind in the frame, impairing egress (1402:10.6.3). Any latching mechanisms need to be very simple to operate from the inside or outside. Do not use hydraulic door closers.

Leave gas installations to the professionals. Such installations need to comply with NFPA 54, National Fuel Gas Code, and NFPA 58, Liquefied Petroleum Gas Code. The standards prohibit liquefied flammable gases inside a structure.

Training Applications

Shipping containers can be a cost-efficient method of acquiring a permanent structural training prop or a mobile training prop. With proper precautions and proper use, they can be an excellent tool in training firefighters.

(13) The high-rise live fire training prop of the West Midlands Fire Service in England. The containers have simulated offices, apartments, and more. (Photo courtesy of the West Midlands Fire Service.)

Ingenuity will expand their applications and utility in training. A recent multicontainer high-rise prop was built for the West Midlands Fire Service in Oldsbury, England (photo 13). The prop is six stories tall and features many fire set areas with different configurations on each floor representing offices, residential occupancies, and so on. It is equipped with a pressurized stairwell, an elevator shaft, and smoke removal equipment and can simulate a wind-driven fire.

Endnotes

Dave Casey, EFO, MPA, CFO, served as the superintendent of the Florida State Fire College and in a similar role for Louisiana’s municipal firefighters. He is the lead author of the IAFC/NFPA/ISFSI textbook Live Fire Training Principles and Practice and coauthor of the Fire Engineering video series “The Right Seat–Officer Development Beyond the Textbook” and “The Right Seat–Volunteer Officer Development.” He served as chief of the Clay County (FL) Fire Department for 11 years and with Sunrise (FL) Fire Rescue and the Plantation (FL) Fire Department. He is the co-owner of Ascend Leadership, a promotional testing and officer development company.