The Model Incident Command System Series PERFORMANCE STANDARDS

This is the fifth in a series of articles on incident command. Here, the authors discuss the importance of having a time standard by which to gauge the efficiency of company units.

What is the average number of personnel typically responding on your pumper and ladder companies? Are there two, three, four, or more firefighters on the unit when it arrives at the incident?

Now, how many of you are associated with a “good” fire company, one that has a high performance level on the fireground? Odds are that few of us believe that we’re associated with a “bad” fire company. But, how do we determine what a “good” fire company is?

As an experiment, ask some of your fellow firefighters to estimate how long it would take your company to complete the following evolution using the typical manning for your company: A pumper company lays one supply line from the hydrant a distance of 100 feet. The hydrant connection and pumper intake connections are made and the supply line charged. A 150-foot preconnected handline (1½, 1¾, or 2 inches) is pulled and advanced to the front door of a dwelling. The preconnect is charged and water is flowing from the nozzle. Start timing the evolution from the time the pumper arrives at the scene until two firefighters, in full turnout gear and self-contained breathing apparatus (SCBA), are on the nozzle and the pumper is supplying water at the proper pressure with the nozzle open.

How does your estimate compare with the actual amount of time this evolution took in your company? How does this compare with what your other personnel estimated? How do you think this compares with other similarly manned departments from around the country’? Do you believe that the time varies from departmyrt to department? Well, it does. We have seen estimates for the same evolution varv from less than two minutes to more than five minutes when polling students from across the United States.

Of course, there are differences in how hoselines are packed in the hose beds, but more relevant are the differences in how evolutions are written, taught, and practiced in various parts of the country. These differences affect the time it takes to complete an evolution. Although some of these differences may be absolutely necessary for a department’s specific area and service problems, how about the differences one sees between the shifts of the same unit or from station to station in a single jurisdiction? If manning is the same, and we are performing the same evolution, why are there differences? The obvious reason lies in the fact that while we have evolutions in our training manuals, our standards are based on quantity and quality only.

Most of us have neglected to include a time standard for our evolutions. Without a time standard, it’s not possible to tell if a crew can meet a minimum efficiency standard. Since time is a factor in fire loss, we must appropriately measure all three factors for effective operators:

- quantity

- quality

- time

Consistently efficient and effective fireground evolutions are a balance between quantity and quality in a given time. How can a fire officer know if the performance of his company is really at an acceptable level? Are there standards against w’hich the officer can identify operational or training weaknesses?

Performance standards

The purpose of performance standards is to determine a company’s capability. In addition to being an excellent method for company officers to measure their own unit’s ability, performance standards also provide an excellent base by which staff officers may better understand their total fire defense system and its ability to perform.

No matter what its size or manpower, all departments should adopt standards, or create, validate, and adopt their own. The National Fire Protection Association (NFPA) Standard 1410 on initial fire attack outlines procedures for performance measurements. Officers are encouraged to use these evaluation guidelines as a basis for performance standard development.

Local criteria

Before beginning to write any performance standards for your department, there are a number of factors that must be considered. It is important to have the standards for your department meet the “real world” environment in which you operate. Performance standards that do not meet this criteria will quickly be abandoned by your operating units, and a “fire school way” and a “fireground way” of performance will be adopted. Establishing realistic performance standards is an effective way of eliminating this type of a double standard in your department.

Look at your manning patterns. Is your department fully paid, combination, or volunteer? Considering each station and unit, what number of personnel can be depended upon to be on each pumper or ladder company on the typical response? In combination and volunteer departments, responses are made on a daily basis with differing numbers of personnel. Performance standards are extremely important measurement tools that help to ensure that company performance will meet a minimum standard, regardless of crew make-up.

Evaluate the structural conditions in your community. Create or adjust your standards to account for typical operations at the most common structures. Look at the type, size, and number of unusual buildings. What typical evolutions are required at these structures? Adjust all evolutions for topography, weather conditions, and other variables that impact your standard operations. This review will help to ensure that the performance standards for your department do, in fact, fit your real world operations.

Set time standard

Some sample performance standards are included in this article. It may be possible to redesign several of those presented in order to accelerate implementing a performance standards program. In almost all cases, considering differences in evolutions from department to department, you will eventually have to design some standards from the ground up. Start with only five or six evolutions and add a few more each year. You will probably build up to about 15 evolutions. It is important to utilize some of your operational personnel when developing performance standards for your department. They are well aware of the techniques used by your fire companies and will incorporate them into the standard development. This process will also give your subordinates a gratifying knowledge that they helped develop the standards.

In any event, the developed standards should be printed and distributed to all units. They should be instructed to practice the standards over a given period of time. Several companies (picked at random) should run through each evolution and the performance time involved should be recorded for each evolution by each company. After recording six to ten samples for each evolution, calculate an average time. This average will be the time that all companies will have to successfully complete each evolution. By analyzing the performance of the companies providing the sample times and comparing this analysis with the standard, training officers can make adjustments to the written standards before their final release. As companies become more proficient, it would be prudent to reduce evolution times by 15 seconds or so where applicable.

Distributing standards and setting the evaluation schedule

Once the standards are distributed, a schedule should be posted, detailing when each company will be evaluated. It is important that evaluations not be cancelled if at all possible. However, if a cancellation does occur, a make-up session should be scheduled. A senior staff officer should be present at all evaluations. Without this commitment, the process will deteriorate very rapidly.

Performance standard evaluations should be conducted frequently, at least four times a year. Once the number of performance standards reaches six or more for either a pumper or a ladder company, only approximately four of the standards should be evaluated each session. However, the companies should not know beforehand on which standards they will be evaluated. This will require the companies to practice all the standards and consequently maintain their overall proficiency.

In addition to providing information about company performance, the standards will provide other benefits as well: company skills will improve; training deficiencies and/or weaknesses in the training program will emerge; it will not be necessary to have “thou shalt train on this” edicts, since meeting the standards is the “real” measurement of any training program.

Testing locale

If there is no training facility available, the evaluations can be accomplished at nearly any place in the community. Parking lots, shopping centers, supermarkets, schools, or secluded streets are preferred. The evaluations should be in a consistent location and the appropriate parts of the evolutions should be written around the testing place and its conditions. There should be as few variables as possible in order to avoid subjectivity.

Dos and don’ts

There are a number of things that must either be accomplished or avoided, regardless of cost:

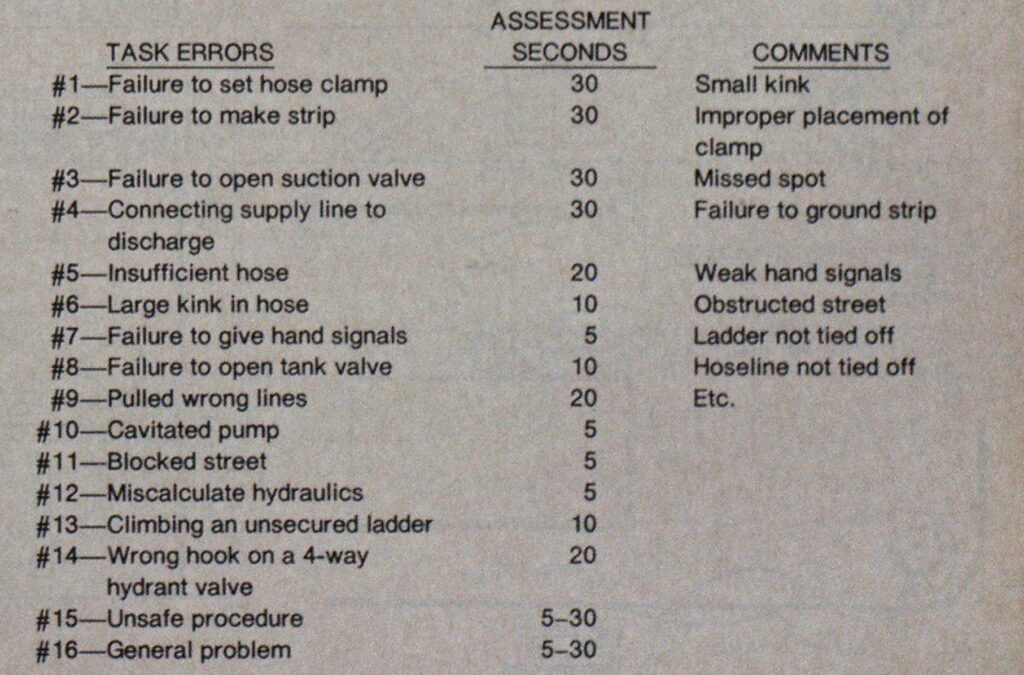

- Emphasize safety. It is important that your personnel train in an atmosphere that promotes safety in its operations. Completing an evolution in an unsafe manner will not enhance the operational capability of your department; it will probably result in the impairment of one or more of your personnel at a critical period during a real operation. Unsafe acts can be dealt with effectively by assessing penalty points in the form of add-on time to the overall evaluation of the standard being performed. These are called task errors. A maximum number of task errors for each evolution should be established (see table below).

- Do not promote competition.The evaluation of the evolution should be a pass/fail system as far as the company officer and personnel are concerned. No other information should be recorded or released that indicates in any way that one company did the evolution in fewer, or more, seconds than another company. If companies are given their times, then you will have a continual speed-up in the execution of evolutions that will result in an increasing number of unsafe practices.

Most companies will periodically fall below a standard from time to time. This shouldn’t be any big issue. Simply re-schedule the performance test. Should a company not meet one or more standards consistently, there could be a deeper problem that must be investigated and addressed. If all companies are weak in one area, the training program is probably weak in that area and needs to be adjusted.

Task error numbers will be typed onto the performance evaluation records. Raters will forward their comments and a list of task errors to the respective companies. Examples of comments and task errors are:

Task Errors

NOTE: Add assessment seconds to total time for the evaluation.

Model policy

The following model policy provides one department’s way of creating a performance evaluation system:

“It shall be the policy that all companies shall be capable of performing all evolutions within the standard time parameters. No company shall commit three or more task errors per evolution for satisfactory completion.

“Starting time is when the first engine pulls up to the scene.

“Time stops when the basics of the evolution have been completed. This means that:

- An effective fire stream is in operation (not necessarily at the correct pressure).

- The relief valve or pressure governor has been turned on (not adjusted to the correct setting).

- All supply lines have been attached to the intakes, intake valves are open, and the hose clamps removed.

- All personnel are in proper turnout gear and SCBA.

“Fine adjustments to pressure, relief valves, and governor settings, and removing kinks should be done to avoid task errors. However, this will not be part of the timed portion.”

Like any model, it is not designed to be copied verbatim. Rather, it should be modified or adapted to suit local needs. The policy contains three very important features: time factor; a list of task errors; and a set of complete evolutions.