SEE THE ENTIRE SEQUENCE HERE >>

By Mike Donahue

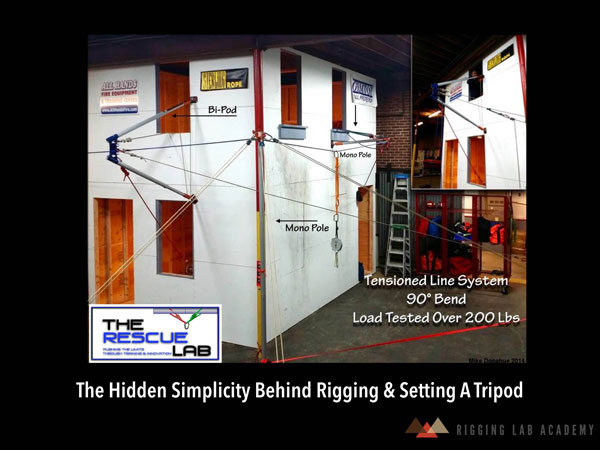

To properly set a tripod, bipod, or monopod, you must first understand that there are multiple forces at work. As a rigging professional, you need to know and understand a few key elements:

1. Where the forces exist in the system and how they were created.

2. The forces and resultants you create need to work hand in hand.

3. Your main line and rear tension line must be perfectly in line with each other.

4. The vector created resultants by your leg tensioning system (MAS) and anchor point should run parallel with the leg. When tracing the resultant, the distance between the MAS and leg should remain relatively the same from top to bottom.

5. The tension you create with the tie-back systems should all be equal.

When tensioning a bipod, tripod, or monopod, your biggest concern is a torsional load. A torsional load is created in one of two ways:

1. When one of the tie-back systems has less tension in it.

2. When your main line and your rear tie-back aren’t in line with each other.

Force travels in straight lines and will seek out a weak point. The force we create and apply to our system is essentially “touching” every piece of it.

Imagine force having a set of hands; when it finds the weak point in the system it will grab it and pull whatever that weak point is connected to towards it.

As an example, we’ll use a bipod. A bipod has two tensioned legs on it. The legs are tensioned from the top down to the ground. When an input force from the main line is applied, it travels down the rope and to the bipod. It then travels through the head and both legs of the bipod. If one of the legs has less tension in it than the other, that also means it has less compression, which is what drives it into the ground. That leg will now attempt to lift up and swing towards the other leg.

You may be wondering what gadget is on the market to ensure you have equal tension in your system. If you have the money, load cells work nicely, however it’s not practical to throw load cells all over your system. There’s a state-of-the-art tool you can use to quickly determine a difference in tension–it’s called the hand, and the good news is you already own two of them. Let’s use the bi-pod example again to explain how this performed.

Stand between both legs, extend your arms, and pluck each tie-back system like a guitar string. You will easily feel a difference in tension if it exists. Should you find less tension in one, adjust and repeat the test until they are equal. If this sounds complicated, it really isn’t. It all boils down to two things: “Tension equally and rig straight.”

One very important key skill is vital in this operation: You need to be able to visualize how your system components will react based on the loads you apply. You may be thinking, “How the heck do I figure out where forces will go and what they will effect without actually rigging anything?” That’s a valid question with a simple answer that of course will take some practice. Here’s how it’s done.

1. First, follow the tension input force from point A to point B. In a tripod, point A would be the head and point B would be both the foot and anchor point.

2. Next, identify any resultant compression points in that same A-B window. Steps one and two are applied to any tie-backs used on the back end of the tripod. (Backend meaning side opposite the main line)

3. Envision the main line being loaded and firing a dose of input tension into the tripod. Visualize how that input force from the opposite will be accepted by the tripod and it’s “force window.” When I use the term “force window,” I’m referring to the tension and compression forces we created in the rear two legs. It’s almost as it the main line input force is hitting a wall and we’re waiting to see what happens.

The most important thing to remember is that you’re in control of any and all forces created in the system. You have the ability to manipulate, move, and control them. Never let them control you.

MIKE DONAHUE is a 17-year veteran of the fire service. He has been a volunteer and a federal firefighter and has been a career firefighter in the Elizabeth (NJ) Fire Department for the past 14 years. He is assigned to Rescue Company 1. He is a rescue specialist with NJ-TF1. He is an instructor at Middlesex Fire Academy and Middlesex County College, where he is an adjunct professor and fire science program coordinator.

MIKE DONAHUE is a 17-year veteran of the fire service. He has been a volunteer and a federal firefighter and has been a career firefighter in the Elizabeth (NJ) Fire Department for the past 14 years. He is assigned to Rescue Company 1. He is a rescue specialist with NJ-TF1. He is an instructor at Middlesex Fire Academy and Middlesex County College, where he is an adjunct professor and fire science program coordinator.