BY ERIC G. BACHMAN

In 1986, the Emergency Planning Community Right-To-Know Act (EPCRA) was enacted as Title III of the Superfund Amendments and Reauthorization Act (SARA). This legislation created the authority for facilities to report the use, storage, and manufacture of hazardous substances. It also mandated emergency planning and preparedness efforts for releases of specially categorized materials.

This legislation impacts the fire service as facilities subject to the annual reporting criteria must submit site- and chemical-specific data to the host fire department. Information such as chemical inventories and storage locations, critical for fire department preincident planning and for post-dispatch operations, are provided. Fire department staff unfamiliar with or untrained in using this facility reporting tool may discard or ignore it. Not using this information in fire department preplanning can foster ill-preparedness and compromise the safety of personnel when called for a chemical emergency.

Although the information below is not a comprehensive overview of EPCRA, it is intended to heighten awareness of the chemical reporting process and its potential impact on fire department preparedness and operations. Title III is broken down into three subtitles; this article focuses on Subtitle B, which covers chemical reporting requirements. Section 312 of this subtitle addresses Emergency and Hazardous Chemical Inventory Forms and establishes facility guidelines for completing Tier II forms. Tier II forms can be important preparedness resources and should be included in fire department preplanning efforts.

REPORTING

By March 1 annually, facilities with certain chemicals on-site that are at or above preestablished quantities must complete a Tier II chemical inventory report. The form provides fire officials with the following valuable preparedness data: the identity of specific chemicals, their physical and health hazards, and a description of storage conditions at facilities in the fire officials’ jurisdiction. A facility must report any chemical that requires an Occupational Safety and Health Administration (OSHA) material safety data sheet (MSDS). This will be called the safety data sheet (SDS) when new OSHA Hazard Communication Standards, consistent with the United Nations Globally Harmonized System (GHS), go into effect. (See “Globally Harmonized System: What Is It?” fireengineering.com, http://bit.ly/15Crnqb).

REPORTING CRITERIA

Before detailing the Tier II form and its contents, you should understand several background terms that will help you better interpret Tier II information. Fire service personnel are familiar with the nine United States Department of Transportation hazard classes. However, chemicals reported on a Tier II form are generally categorized as either an extremely hazardous substance (EHS) or a non-extremely hazardous substance (non-EHS). An EHS is a material that the Environmental Protection Agency (EPA) deems to be significantly toxic to humans. The EPA maintains The Chemical List of Lists, which comprises more than 360 chemicals (http://1.usa.gov/19erMvl). Chemicals not on the EPA list would be considered non-EHS substances. It is important to note that the term non-EHS does not mean nonhazardous.

A facility must report a chemical on a Tier II form only if the amount on-site meets the Reportable Quantity (RQ). The RQ is the minimum amount of substance a facility has on-site at any one time during a calendar year, even for one day. The RQ represents total on-site quantities aggregated for each chemical regardless of packaging or location. The RQ for all non-EHSs is 10,000 pounds. Chemicals deemed to be EHSs have individual RQs. But some non-EHSs, such as propane (photo 1), diesel fuel, and other hydrocarbons, each have an RQ of 10,000 pounds. If a facility maintains an inventory of a non-EHS below the 10,000-pound RQ, it does not have to include it on the Tier II report. Photo 2 shows an extensive non-EHS chemical inventory. Since the quantity of each chemical is below the RQ, it does not have to be reported. EHSs, however, have individual and wide-ranging RQs, some as little as one pound.

|

| 1 Photos by author. |

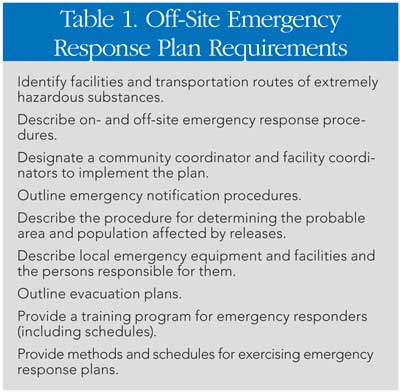

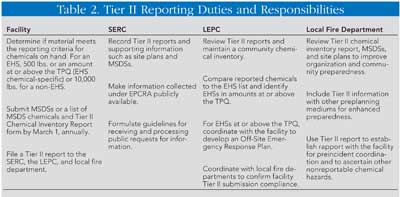

Another important criterion is the threshold planning quantity (TPQ), which applies only to EHSs. If a facility maintains an EHS at or above its TPQ, it must develop an off-site emergency response plan (OSERP). OSERPs are a part of the original SARA Title III legislation but are not discussed here (Tables 1, 2) (see “Off-Site Emergency Response Plans: A Preparedness Tool,” Fire Engineering, November 2011, 51-58, http://bit.ly/1aSLhhF).

EHSs have a RQ, which is defined as 500 pounds or more, or the TPQ, whichever is less. For EHSs, the TPQ may be lower than the RQ. Chlorine, for example, is an EHS with a TPQ of 100 pounds. Because the TPQ is less than the generic 500-pound EHS RQ, it must be reported on a Tier II form when inventories meet or exceed 100 pounds.

REPORTING PROCESS

Since the inception of SARA Title III, Tier II reports have remained basically unchanged. Advances in word processing and electronic form filling capabilities have allowed for some informational enhancements. However, the basic format has not changed much. Some facilities may still use hard copy Tier II forms, but the use of electronic filing media is ever-increasing and today is more the rule than the exception.

A facility with reportable chemicals must file its completed Tier II report with the state emergency response commission (SERC), the local emergency planning committee (LEPC), and the local fire department with jurisdiction. Reporting methods may vary from state to state. In Pennsylvania, the state Department of Labor and Industry/Bureau of Occupational & Industrial Safety PENNSAFE Program is the repository for all Tier II reports.

Pennsylvania facilities submit their annual Tier II reports electronically into the online Pennsylvania Tier Two System (PATTS). Facilities in this state are required to report the presence of a new hazardous material within five business days after the hazardous material is first present at the facility. Accordingly, facilities must submit a Tier II reporting form, an MSDS, and an updated site plan to the bureau’s PENNSAFE, their LEPCs, and the local fire department if they bring on-site any new hazardous material meeting the established threshold requirements that had not been reported during the previous calendar year. Hazardous materials reported under this requirement must be reported again at the time of the annual filing on or before March 1. In other states, the initial reporting criteria may differ.

Reporting compliance to county LEPCs vary. A county LEPC may maintain its own on-line electronic Tier II form submission program, may require filing of hard copies, or may accept both formats. For example, some Pennsylvania county LEPCs have secured access agreements with PENNSAFE to review and process local county chemical preparedness efforts from the state Tier II database.

REPORTING ISSUE

Regardless of the submission practice at the state and county levels, a common filing issue is the failure of reporting facilities to submit Tier II reports to the local fire department. The reasons are many. One is that the facility assumes that on-line Tier II filing with the state is a one-stop reporting shop and its reports will filter down to the local level. A second common reason is that the facility does not know which fire department responds to the facility and so may submit Tier IIs to the wrong fire department. For some sites, a corporate office or a consultant distant from the facility generates the Tier II reports and may be unfamiliar with the local jurisdiction boundaries.

Often, the LEPC may not receive a report for similar reasons. Pennsylvania comprises 67 counties with 2,575 local municipal governments and more than 2,400 independent fire departments. Jurisdictional boundaries are not always obvious or symmetrical. If the local fire department does not receive a Tier II form, it may be unaware of the presence of such materials in its jurisdiction and hence be ill-prepared when dispatched. Fire departments and LEPCs should maintain a good rapport with their industrial facilities as well as with exempt facilities such as hospitals, service stations, and municipal facilities, including water treatment plants, to ensure that community hazards are well communicated.

EXEMPTIONS

As much an asset as Tier II forms can be, fire department personnel should be cognizant of several compromising reporting circumstances. First, the information reported on a Tier II reflects the previous year’s inventory. A Tier II report received in 2013 represents reportable materials that were on-site in 2012. Second, the 10,000-pound reporting threshold for non-EHS chemicals may exclude reporting of numerous hazardous commodities.

Also, several exemptions affect comprehensive chemical reporting.

- Food, food additives, food coloring, drugs, and cosmetics regulated by the Food and Drug Administration (FDA) are exempt. Any substance present as a solid in any manufactured item to the extent that exposure to it does not occur during normal conditions of use is exempt. An example would be elemental components of steel like phosphorus. Exposure is a possibility when phosphorus exists alone, but exposure to it does not occur when it is part of finished steel.

- Substances used for personal, family, or household purposes or if present in the same form and concentration as a product packaged for distribution for use by the general public, such as paint thinner, are exempt.

- Some products used at certain venues also are exempt.

- – Substances used in a research laboratory, hospital, or other medical facility under the direct supervision of a technically qualified individual are exempt from reporting.

- – Any substance used in routine agricultural operations or that is a fertilizer held for sale by a retailer to the ultimate customer is exempt.

- – Government-operated facilities are also exempt from reporting. Certain water, wastewater, and sewage treatment plants operated by governmental authorities are not mandated to file a Tier II even though certain processes use EHSs such as chlorine and sulfur dioxide.

All of these exemptions make it all the more important to engage in comprehensive facility preplanning. Just because a fire department does not receive a Tier II report from a facility does not mean no hazardous chemicals are in use or on site.

PREPAREDNESS TOOL

When the capabilities and limitations of Tier II reports are understood, they can provide provisional, yet valuable, information. Study them to identify the commodity and its respective physical and chemical hazards. Tier IIs should be used to supplement other department preincident preparedness media and efforts. (See “Tier II Chemical Inventory Form: A Preplanning Resource,” Fire Engineering, March 1998, 182-186, http://bit.ly/1dZmf2s.)

UPCOMING CHANGES

Effective January 1, 2014, a final rule under the EPA 40 CFR Part 370 becomes effective that changes the basic Tier II format and mandates additional information. The new format also provides for optional site-specific and chemical information. The proposed basic administrative Tier II report template (http://bit.ly/1emTmuZ) is a significant change from the previous Tier II landscape template. Some of the features, changes, and modifications include the following:

- At the top, outside of the table, is a checkbox that indicates if the information submitted is identical to that of the previous year.

- Next is the date range. Remember that the Tier II, although it must be submitted by March 1 of the current year, reflects the chemical inventories during the previous calendar year.

- The facility identification box is expanded to capture general information including the facility name, physical location, and latitude and longitude coordinates. A new field provides for the maximum number of occupants on-site at any one time. This is provided to assist officials in their planning and preparedness efforts. Another new feature is a checkbox to denote whether the facility is staffed or unstaffed. Power substations, cell towers, telephone switching sites, and other sites are typically unstaffed. Although the water chlorination station in photo 3 is visited periodically, it operates automatically.

- This section also requires the North American Industry Classification System (NAICS) code, which is a federal business classification system. This code is not relevant for emergency preparedness.

- Next is the facility phone number. This is optional because some facilities, such as unstaffed sites, do not have a hard-wired phone.

- The facility identification section also provides data on the EPA Toxic Release Inventory (TRI) and Risk Management Program (RMP), which are beneficial to certain environmental compliance entities. TRI and RMP data are submitted separately, not in conjunction with a Tier II. TRI and RMP components apply to facilities that maintain certain quantities of certain regulated materials, especially EHS materials.

- Next is a checkbox regarding whether the facility is subject to EPCRA Section 302. Marking the Yes box indicates the facility maintains at least one EHS at or above the TPQ. This is a catalyst for the LEPC to develop an OSERP.

- Another checkbox pertains to whether the facility is subject to Section 112(r) of the Clean Air Act (CAA). Facilities regulated by the CAA are required to coordinate emergency response actions with LEPCs.

- The form requests additional applicable facility identification numbers associated with Dun & Bradstreet. A Data Universal Numbering System (D-U-N-S) is a nine-digit number used as a standard business identifier number for each business physical location. Businesses are required to register a D-U-N-S number with the United States federal government for contracts or grants.

PERSONNEL AND CONTACTS CHANGES

Prior to the adoption of the new format, the Tier II listed basic information for the owner/operator and emergency contact personnel. The new Tier II still includes identification of those individuals but has been expanded to capture more subject matter expertise. The contact section includes the following:

- Owner/Operator Information. Like the older Tier II version, basic information required includes the name, address, and telephone number; it now also requests an e-mail address.

- Parent Company Information. This new but optional section requests the name, address, phone number, D-U-N-S number, and e-mail address of a parent company, if applicable.

- Facility Emergency Coordinator. This section is applicable to facilities that are subject to emergency planning because they maintain an inventory of an EHS at or above the TPQ. Under EPCRA Section 302, a facility must designate a facility emergency coordinator to assist in planning.

- Tier II Information Contact. This new section allows for the identification of the source who compiled the Tier II. Often, the person who developed the Tier II is not an employee or directly associated with the facility. Tier II development may be a contracted service completed by a consultant. Questions or concerns regarding the development or content of the Tier II can be facilitated through this contact person.

- Emergency Contacts. As in the older edition, the new Tier II provides for two emergency contact people. Each contact should provide the name, title, and daytime and after-hours phone numbers. The new format also provides the e-mail address for the preincident contact. This section may include the same individual listed as the facility emergency coordinator, especially if the facility meets the off-site planning criteria. However, certain key facility personnel with comprehensive knowledge of facility or process system operations should be listed. For example, the designated facility emergency coordinator may be the human resource manager or another individual with administrative duties. These individuals, while having responsibility for facility oversight, may not have comprehensive knowledge or skills with specific facility processes or infrastructure. One intent of the emergency contacts section is to identify subject matter experts within the facility such as the maintenance supervisor or a specific operator. Unstaffed facilities’ emergency contacts may not be locally available (e.g., a district or regional manager, a corporate or a contracted environmental service, or even a corporate emergency hotline). There is no quality assurance or vetting of the Tier II information by SERC or LEPC. I have seen Tier II reports with emergency contacts listing nonfacility personnel such as the local fire department as well as the Chemical Transportation Emergency Center (CHEMTREC). If such contacts are provided, ask the facility to provide appropriate facility personnel contacts.

- Certification. Every Tier II form must be certified as correct through the signature at the bottom of the administrative page. In many cases, the chief executive officer, president, owner, or other individual signs the certification. Although signed by a facility leader, that person may not have comprehensive knowledge of the contents, which is the reason there is a new Tier II Information Contact section to complete.

- Reporting Ranges Table. The Tier II administrative page provides a Reporting Ranges table that was not published on previous Tier II editions. Each code between 01 and 13 represents an inventory weight range in pounds. This is key since liquid chemical inventories are reported in pounds, not gallons. This table has changed with the newly adopted rule. Previously, there were 11 inventory weight ranges. The new table expands the number of codes while at the same time narrowing the ranges. In the old table, Inventory Code 04 represented a weight range of 10,000 to 99,999 pounds. In the new table, the 04 code represents a weight range of 1,000 to 4,999 pounds.

CHEMICAL LIST

The chemical reporting section is similar in format to the previous template. There are, however, several column modifications. Under the Chemical Description column, the chemical name should be listed in addition to the respective Chemical Abstract Service (CAS) registry number. The CAS number is a classification system for chemical manufacturers. There are provisions for reporting mixtures, which are not addressed in this article.

Next are two checkboxes to denote if the material is an EHS. Although a chemical may be marked as an EHS, an OSERP may not be required. An EHS may be reported because the RQ is met, but the inventory is below the TPQ. For example, sulfuric acid is an EHS. The RQ is 500 pounds, but its TPQ is 1,000 pounds, so a facility that reports 750 pounds of sulfuric acid is meeting the reporting criteria, but an OSERP is not mandated because the inventory is below the TPQ. In photo 4, the quantity of sulfuric acid in the elevated tank arrangement must be calculated by weight to determine if the RQ and the TPQ have been met.

Checkboxes are provided to indicate the physical state of the materials—liquid, solid, or gas. A Trade Secret box, when marked, indicates a specialty chemical use. If a facility claims a Trade Secret, the chemical does not have to be specifically listed, but a generic class or category description must be provided. If a mixture is reported, the components can be separately listed.

The second column indicates the Physical and Health Hazards. This does not represent a hazard class, like the nine United States Department of Transportation hazard classes, but represents five generic hazard potentials. All that apply should be marked.

The third column reveals the Inventory. Two inventory amounts are provided: the maximum amount on-site at any given time and the average daily amount on-site. This is where the Reporting Rage code will be noted. Additionally, the number of days on-site must be indicated. Some products may be on-site year-round while others may be seasonal. This component will not list specific times of the year such as March through July but rather a corresponding numeric value.

The next column reveals the Type of Storage. Previously, a letter code in this field referred to a specific container type. This required research that in most cases was not readily available or maintained, especially by a fire department. Examples include letter “A” for an aboveground tank, “D” for a steel drum, and “K” for a box. The new rules vacate this practice and require specifying the container type without referencing a letter code. This section should specify the container type such as a tote/intermediate bulk container (IBC) (photo 5), a bucket (photo 6), or a compressed gas cylinder—fixed rack (photo 7).

The next column describes the Storage Conditions. Previously, this column, too, was code associated by a number range between 1-7. The number “1” meant the product was stored at ambient (atmospheric) pressure. The number “4” represented storage at ambient (room) temperature. The new rules vacate this practice, and the column should be a narrative description, such as stored at ambient temperature, in less than ambient pressure, in cryogenic conditions, and so forth.

The Storage Location column remains a narrative description of where the material is located. It may specify a certain location or be reported as used throughout. Be cognizant of the processes involved through preplanning. The Tier II may report that the ammonia tank in photo 8 (an anhydrous ammonia tank in a cold storage facility) is in a certain location. However, ascertain how it is piped (photo 9) so that emergency crews are aware of other potential sources of a release. A facility may choose to claim “Confidentiality” by marking the respective checkbox. In this case, the facility would have to initiate other documentation media. This notation should spur further cooperative intelligence gathering with the facility.

OPTIONAL OBLIGATION

The last column, Additional Reporting Information, is new. It also is optional. As mentioned earlier, a reporting condition is whether the chemical inventory meets the RQ. The checkbox entitled “Below Reporting Threshold” is optional and basically when marked, the facility is providing a courtesy notification of that chemical’s use. Some states and local regulatory entities may have stricter reporting requirements than required in 40 CFR. A checkbox denotes that the chemical reported is required under another state or local authority. Hopefully, facilities will embrace the “optional” Additional Reporting Information and report use of hazardous commodities that are below the RQ.

This section may also list EHSs that are maintained below the RQ before unknowingly encountering the material after the fact. For example, while investigating the cause of an automatic fire alarm at a facility after hours, crews observed three portable 150-pound cylinders of anhydrous ammonia in one room of an industrial building. The ammonia cylinders had nothing to do with the alarm activation, but they were recognized during the investigation. On incident termination, crews reviewed preincident data and the most recent Tier II report, finding that the ammonia was not listed. Anhydrous ammonia is an EHS, and its RQ and TPQ are both 500 pounds. Collectively, the facility maintains 450 pounds. This is below both the RQ and TPQ, and the facility has no legal obligation to report it. A release, however, could be just as dangerous to emergency personnel as if the facility maintained 501 (reportable) pounds. This “nice-to-know” information could necessitate more cautious fire department response strategies and tactics.

Although this option should be recommended through preplanning and by emergency managers, it will likely only affect those facilities that already file Tier II reports. Non-reporting facilities likely will not be aware of this option or commit resources to develop an unmandated report. But when optional data are provided, it is an opportunity for fire department staff to learn more about the hazards that lie in wait and should foster more intensive preincident preparedness efforts.

CASE STUDY: WEST, TEXAS

Awareness of the role and impact of Tier IIs has recently been brought to the forefront because of the West, Texas, explosion that occurred April 17, 2013. Fourteen people died, including 11 first responders, after a tremendous explosion occurred at the West Fertilizer Company (WFC). This case study example is not a defense or criticism of the West Fire Department (WFD) or the McLennan County Local Emergency Planning Committee (MCLEPC). It will not speculate the incident cause, comment on the fire department’s actions, or condemn or endorse any actions taken. Those interested in this event can only evaluate the facts, many of which currently are unclear. However, the following review is meant to correlate certain intentions, capabilities, and limitations pertaining to the use or lack thereof of Tier II data submitted by the WFC. It is intended to be a learning tool for others to consider and incorporate Tier II data in their preincident preparedness efforts.

A key factor, as mentioned above, is the RQ. A facility has no legal obligation to report chemicals maintained below the RQ even though they still present hazards to the community and responders. A second issue relates to ammonium nitrate. Known as a fertilizer, it is not deemed an EHS, and the 10,000-pound RQ would have applied. Media reports indicate that the WFC maintained inventories of ammonium nitrate well above the RQ. WFC’s Tier II compliance history is not known. Although media reports note that the state authority in Texas has a record of receiving a Tier II in February 2013, the MCLEPC has no record of it, and it is unclear if the fire department was provided with a copy. Because ammonium nitrate is not an EHS, the facility would not be required by the MCLEPC to develop an OSERP.

WFC reportedly maintained anhydrous ammonia, also in excess of the 500-pound RQ and TPQ. The Tier II form should have reflected the ammonia inventory, and the facility would have been required to develop an OSERP. The board’s chairperson presented preliminary findings before the U.S. Senate Committee on Environment and Public Works. See http://1.usa.gov/1hnZYrH.

An analysis of line-of-duty deaths (LODDs) and close-call incidents could show that many of these critical incidents result from a long line of events, actions, and inactions that contribute to tragic or potentially tragic outcomes. For the West, Texas, incident, that chain may include facility chemical reporting compliance, LEPC planning administration, and fire department preplanning.

DISCLAIMER

I am not familiar with Texas laws pertaining to Tier IIs or with the operations of the local authorities, including the fire department. I am not privy to any special information regarding the incident; I am limited to the public information available. How these facility, fire department, and local emergency planning committee factors directly influenced the outcome does not change the tragedy. It should, however, cause fire departments and emergency planning groups to evaluate their use, implementation, and administration of mandatory facility chemical reports.

Tier II reports are often filed, discarded, or ignored without comprehensive review by fire officials. Like any tool, the report has special purposes and limitations, and understanding both is key in preparedness. Fire departments must take advantage of submitted Tier II reports to understand some of the chemical threats to better safeguard fire department personnel. Don’t wait for the publication of a formal LODD report to galvanize improving your evaluation and the use of Tier II reports and OSERPs.

● ERIC G. BACHMAN, CFPS, a 30-year-veteran of the fire service, is former chief of the Eden Volunteer Fire/Rescue Department in Lancaster County, Pennsylvania. He is the hazardous materials administrator for the County of Lancaster Emergency Management Agency and serves on the local emergency planning committee of Lancaster County. He is registered with the National Board on Fire Service Professional Qualifications as a fire officer IV, fire instructor III, hazardous materials technician, and hazardous materials incident commander. He has an associate degree in fire science and earned professional certification in emergency management through the state of Pennsylvania. He is also a volunteer firefighter with the West Hempfield (PA) Fire & Rescue Company.

Fire Engineering Archives