By Jeremy Rifflard

Rope rescue systems can make an operation safe by protecting rescuers from injury. They make it easier to move heavy loads. Rope systems can create a tether that limits the distance a rescuer will travel and will keep the rescuer from falling off a ledge or from falling backward on a steep slope. These limits can be adjusted inward or outward by adding a progress capture device. Many engine and ladder companies carry enough equipment to create basic rope systems. Using rope equipment to construct odd mechanical advantage systems will enhance the safety of your rescue team.

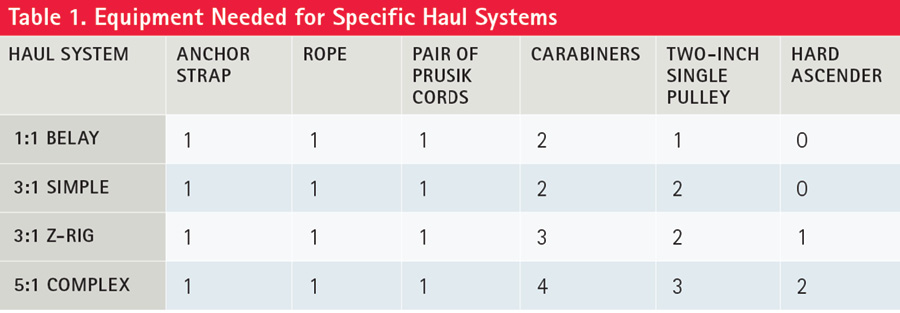

Odd rope systems have a mechanical advantage (MA) with an odd number as opposed to an even number, including 1:1, 3:1, and 5:1. It is not difficult to increase or decrease the MA within the odd family. The best known 1:1 MA is a Prusik-minded pulley belay system that is approved for a two-person load. It is common to construct a Prusik-minded pulley belay system alongside a primary lowering or hauling system.

1:1 MA

To create a 1:1 MA, begin with a ½-inch static kernmantle rope. Tie a knot on the end of the rope. I prefer a single-loop eight knot on a bight, which is common for use at the end of a rope. It is easy to tie and untie. Leave a short tail about four to six inches long. Check with your local jurisdiction regarding the requirement of a safety knot for the tail of the single-loop eight.

Attach the knot to the load you want to move. Working your way back from the load, the rope should go through a two-inch pulley (a pulley wheel should be at least four times the diameter of the rope) that is attached to a fixed anchor. A pulley that does not move location during a haul will not add any MA. To the anchor, add a pair of 9mm Prusik cords onto the load side of the rope going around the pulley (photo 1).

|

|

(1) The completed Prusik-minded pulley belay system. (Photos by author.) (2) The completed simple 3:1 haul system.

If a force is applied from the load end, the Prusik cords will grasp the rope and capture the progress. This is extremely important. Progress capture is a great safety feature that stops the system from expanding when you are hauling an object. If you are a rescuer on an incline, you want to capture the upward progress. When somebody lets go of the rope, you do not want rescuers to fall backward.

The 3:1 Haul System

Another staple of rope rescue is the simple 3:1 haul system with progress capture. This system creates an MA that makes it easier to haul heavy objects. It can be used to move an object vertically or horizontally on a flat plane and to aid rescuers walking on a steep surface with a patient in a Stokes basket. With practice, the 3:1 is simple to construct with minimal equipment.

The theory of a 3:1 MA is that three ropes are assisting in moving a load with the aid of a traveling pulley. Therefore, in theory, hauling a 150-pound load would take the input of 50 pounds of force on the haul line. This theory does not consider the friction of the traveling pulley, anchor pulley, directionals, edge protection, wet ropes, or other factors. When these variables are considered, you are evaluating the “actual” MA, which is not as great as the “theoretical” MA.

To construct a simple 3:1 MA system, begin with a Prusik-minded belay system. Take the rope from the side without the Prusik cords and place it into a two-inch pulley. Attach the pulley and rope to the carabiner on the load. Bring the remaining portion of the rope toward your anchor. This portion of the rope is for hauling. You have completed the 3:1 haul system (photo 2).

This system will work well when you are hauling a load horizontally and you have enough rope to construct the system. In theory, you will need three times the distance from the load to the anchor to build the 3:1. If you are 50 feet away from the load, you may need 150 feet of rope to construct the 3:1 haul system (photo 3).

|

|

(3) A simple 3:1 haul system is attached to a concrete barrier, which will be moved. The length of the rope will be three times the distance between the load and the anchor. In this operation, the haul will occur after the friction with the ground is reduced by placing lumber and steel rollers under the concrete. (4) The completed 3:1 Z-rig haul system.

The 3:1 Z-Rig System

The 3:1 Z-rig is a modified version of the simple 3:1. The difference is that the Z-rig moving pulley is not attached to the load. It is attached to the load line (the first rope leaving the load) at any point between the load and the anchor (photo 4). It can be attached with a 9mm soft accessory (Prusik) cord or a hard cam ascender. This attachment point is closer than the point the load requires and will take less rope than the simple 3:1 MA system. This is a primary advantage of the Z-rig. The traveling pulley will move more quickly than the load and will have to be reset one or more times. The closer the attachment of the ascender (photo 5) is to the anchor, the more resets will be needed to complete the haul. This is the primary disadvantage of the Z-rig.

(5) An ascender attached to a rope.

Another use for the Z-rig is as a horizontal haul system built on the roof of a building with the rope making a 90° bend over the edge. The three ropes of the simple 3:1 should not go onto an edge roller and over the side of the structure. The Z-rig can be built on the horizontal surface and the single line to the load can make the 90° bend over the edge (photos 6-7).

(6) The rescuer on the basket is being hauled upward with a 3:1 Z-rig haul system. (7) The rescuers pull the haul line on the 3:1 Z-rig to raise the basket.

The Complex 5:1

If you are hauling with a 3:1 Z-rig haul system and the weight feels too heavy to effectively move, you can easily upgrade to a complex 5:1 haul system. A complex system does not refer to the difficulty in assembly; it refers to the two pulleys of the system that will converge during the haul. Calculate the MA in a complex system by using tension segments, not by counting the number of ropes between the anchor and the load.

To construct the complex 5:1 MA from the Z-rig, form a bight in the haul line and place it into a two-inch pulley. Attach the pulley to the second line, leaving the load with a Prusik cord or a hard cam ascender. Do not attach the pulley to the anchor. If you attach to a stationary object, it does not increase your MA; it will only change the direction in which you haul the load. This second moving pulley creates the complex 5:1 mechanical advantage system (photos 8-9).

(8) The complete 5:1 MA complex haul system. (9) The 5:1 MA complex haul system is being used to move the heavy slab of concrete across the steel rollers.

Plan the rope rescue operations with the flexibility to change the MA of the haul system. You may use a Prusik-minded pulley belay system on a rescuer walking down a low-angled slope. By constructing this 1:1 MA system with a Prusik safety, you control the rescuer. You may choose to lower with an eight plate when rescuers are not carrying a patient and there is a minimal chance of falling.

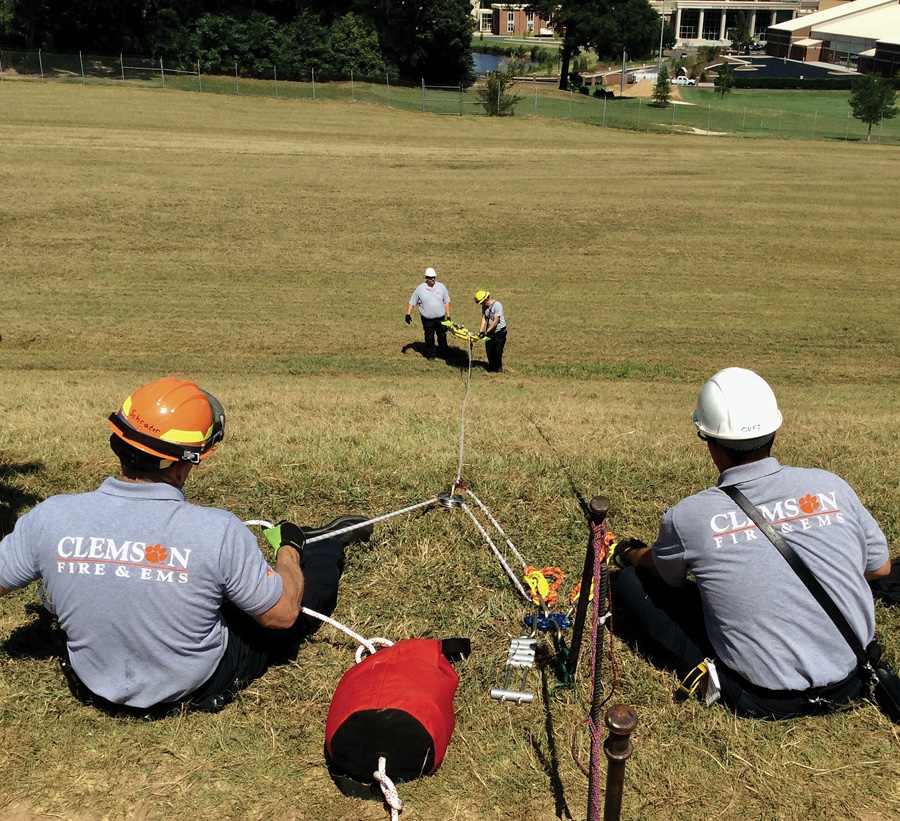

When rescuers reach a predetermined point, upgrade the MA to a 3:1 MA Z-rig with progress capture or a 5:1 MA complex system to convert your low-angle lowering operation into a safe haul system. If your haul is very easy and you are resetting the system often, you may need to downgrade to a system with less MA. You can make this adjustment in the system when the progress capture cam is holding the load (photos 10-11).

(10) These Clemson University (SC) firefighters are training on a low-angle scenario. They are using an eight plate to control the descent of the rescuers on the basket. When rescuers reach the victim at a distance beyond the length of a simple 3:1 MA, they will construct a 3:1 MA Z-rig to help bring the team to the top of the slope. (11) Fort Lauderdale (FL) Firefighter Rolando Busto is being lowered on a Prusik-minded pulley belay (1:1 MA with progress capture), which will stop him if he moves beyond the predetermined location. (Busto has a second rope that he will attach to the patient.) After the rescuer secures the patient, they will be hauled upward with a 3:1 Z-rig MA system.

Moving heavy objects and securing rescuers can be done with rope and odd MA systems that have incorporated progress capture. Using odd mechanical advantage rope systems can reduce injuries caused by moving heavy objects. Operating on the edge of structures is safer when progress capture is used. With training and a minimal amount of rope rescue equipment, you can create systems to keep firefighters safe.

Jeremy Rifflard is the lead technical rescue instructor at the Coral Springs (FL) Regional Institute of Public Safety. For the past 15 years, he has been a rope recue instructor and subject matter expert for military urban search and rescue exercises with Technical Rescue Traiing LLC. He is a captain with the Fort Lauderdale (FL) Fire Department and a rescue team manager for FL-TF2. Rifflard’s most recent urban search and rescue task force deployments were to the Haitian Earthquake and Hurricane Ike.