By Mike Donahue

Let’s look at two rigging methods used in a confined space/collapse atmosphere. They can of course be applied anywhere, but for the purpose of this article we’ll operate in tight quarters. One of the biggest problems I see and have experienced myself is fire departments training on the same skill set over and over. Sure, you become very confident at that particular skill set, but what happens when a rescue operation requires you to travel outside your skill set? You’re stuck; stress sets in because you don’t know what to do, and once that happens your operation will go downhill fast. Firefighters must train, train, train outside that box. If you can learn to develop operational answers outside that box, then performing a rescue operation inside the box should feel effortless.

FIRST CONCEPT

One of my favorite pieces of rope equipment is the mini set of fours (photo 1). The mini fours are such a versatile, powerful, and portable piece of equipment that can work wonders. The space our operation is being conducted in has several different runs consisting of tight turns, elevation changes, and debris. The one oddball tool I’m going to add to the mix is a halligan.

(1)

The biggest challenge in this operation will be moving the patient from point A to point B. The rope and hardware we carry gives us the ability to move and steer our patient wherever we want them to travel. Working in confined spaces, there’s always the chance to be confronted with obstacles, different elevations, or just challenging locations. I’ve quite often see as well as been part of a training program where a haul system is built on the exterior of the confined space for victim egress assistance…but it stopped there. If you need to move this victim around in the space prior to making egress, that system is mostly useless. The mini fours will provide you portable power to get the job done in the space.

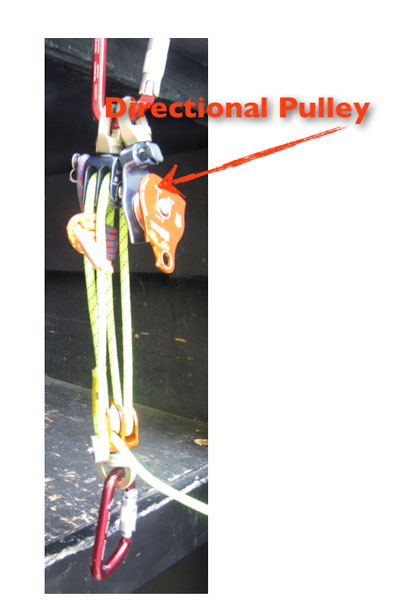

Prior to entering the confined space, always grab some extra hardware, such as carabiners, pulleys, prusiks, and a few lengths of webbing. Entering a space without any hardware is like showing up to a job site with an empty toolbox. Should something go wrong, you may need hardware to fix said problem. Lastly, add a direction pulley to the mini fours. This forethought will make switch hauling simple. You can see pictures of the direction transfer in photo 2.

(2)

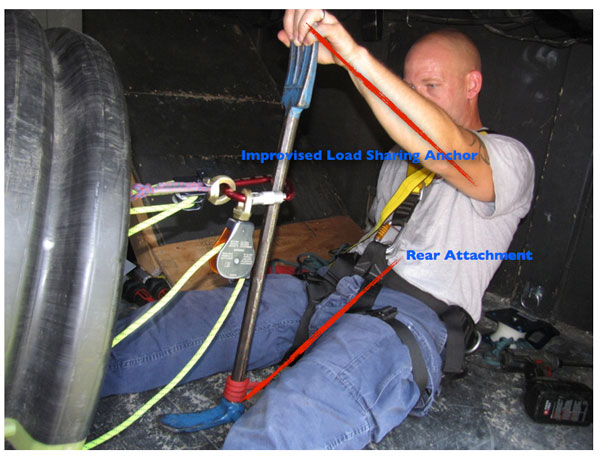

The halligan is your portable anchor. With these two small steps you’ll create a pretty rock-solid portable anchor. Prior to entering the space, take a prusik (about 2-feet long when tied) and apply a triple wrap around the bar right above the adze end. Now run the prusik under the adze and place the halligan between your legs. Next, pass the carabiner under you connecting it to the rear of your harness. Use the power of leverage to create strength in this anchor. Prior to hauling, pull back on the halligan. When doing this, strive for the 45º mark. You have essentially created somewhat of a load-sharing anchor(photo 3). It’s important when pulling (applying) force to the halligan bar that you do so from the fork end or top of the bar or you will lose the power of leverage applying force from the bottom. You will also fail to create the “load-sharing anchor,” as well. The difference in power between applying force from the adze end (bottom) vs. the fork end (top) is roughly 100 lbf.

(3)

Once you’re set “call the haul,” meaning notify your partner to begin. The change of direction comes in handy now because your partner can haul from the opposite direction. The swivel pulley I use (photo 4) for the direction means I never have to remove it from the rope. The side plate unlocks, allowing you to quickly remove the rope. Once the haul is complete, collapse the system and continue your egress.

(4)

SECOND CONCEPT

The second idea is a variant of the traditional definition of “outside the box,” meaning breaking free of your normal training routines and trying something new. Do you truly understand why you do what you do when it comes to technical rescue skills, such as why a raker shore is built the way it is, or how a trench shoring system works? Most rescuers understand up to a certain point and leave it at that. Let’s travel beyond that wall and understand what’s behind something we’ve built for years, something that is also one of the first skills you’ll learn about in a rope rescue program…anchors.

Building anchor systems is not a difficult task once you understand the parameters you have to work within. Generally, you size-up your anchors, decide whether their bombproof or questionable, create your anchor system, and move on. This is “inside the box” rigging. Let’s instead figure out exactly how the angles we create in our systems affect the entire system.

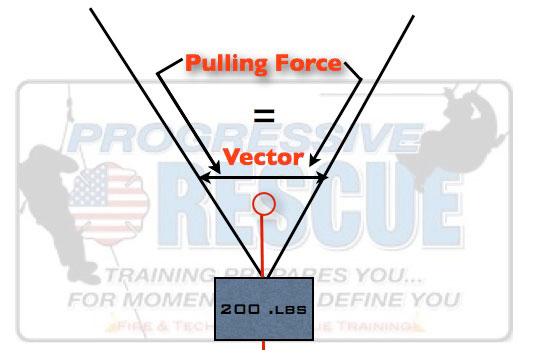

When rigging systems, you’re working with straight lines and angles. Load + angle = Vector, which equals resultant force. If you’re confused on what resultant force means, see photo 5, which also shows a load sharing anchor system. You have two independent anchor points that will share the load applied. Here’s a simple example of the benefits of a load-sharing anchor and something you can do right at home. I’m holding a load with two hands and, of course, in turn, my two arms. We’ll call my hands the carabiners and my arms the rope. My back then becomes the anchor, because the load is traveling up my arms and into my back. The load weighs 100 pounds, therefore my back is seeing the full load. Now take two people supporting the load. Each person is using one arm to support it. Therefore the load is being split between each person.

(5)

My grateful back is now experiencing roughly half the load…or is it? Angles play a big part in our rigging systems, and here’s why. The angle I created with the load-sharing anchor is roughly 45°. At 45°, the 200-lb. load is spilt 50/50, give or take one or two pounds. If I open that angle up to 120°, each leg is seeing 200 lbs. because the system is in a state of equilibrium. If you have an angle of 174°, how do we figure out how much load each anchor is seeing? All you need is a calculator. Take your 200-lb. load and cut it in half. Then take the cosine of half the angle and divide it by half the load. The formula looks like this:

100 / (cos 87) = 1,910 pounds on each leg of the anchor.

That’s a lot of weight being transferred to each anchor point with such a small load. Throw a victim in a stokes basket into the mix Now you have a load of let’s say 490 pounds. Here’s the math:

245 / (cos 87) = 4,681 pounds on each leg of the anchor.

As you can clearly see, angles are important, and knowing how to calculate the actual anchor hit (load force on the anchor) is quite important. Figuring things of this nature out only really happens when you travel outside your comfort zone. The only way to get better and become great at what you do is constantly push forward and expand your knowledge base. Working and learning inside the box gives you four walls of limits. Travel outside the box and your ability to improve your knowledge base and skills is unlimited.

Mike Donahue has 17 years of fire service experience and has been a career firefighter in the city of Elizabeth, New Jersey, for the last 13 years, working out of Rescue Company 1 for the past 10 years. Mike teaches a Middlesex County College as an adjunct professor and acts as the Fire Service Program Coordinator. Mike is the owner of Progressive Rescue and can be reached at progressiverescue@gmail.com.

Mike Donahue has 17 years of fire service experience and has been a career firefighter in the city of Elizabeth, New Jersey, for the last 13 years, working out of Rescue Company 1 for the past 10 years. Mike teaches a Middlesex County College as an adjunct professor and acts as the Fire Service Program Coordinator. Mike is the owner of Progressive Rescue and can be reached at progressiverescue@gmail.com.