IMPROVE TANKER EFFICIENCY WITH AN AIR-OPERATED DUMP VALVE

APPARATUS/EQUIPMENT

Any innovation which improves efficiency, reduces manpower requirements or improves safety in tanker water supply operations is certainly worth considering. A low-cost accessory that combines all three benefits at a minimal cost is the airoperated dump valve.

The air-operated dump valve allows a tanker to operate in a shuttle with only the driver on board. It is no longer necessary to have a person ride the rear step to operate the dump or to have people moving between the tanker and drop tanks to open the valve. Those who previously performed these tasks are now available for other assignments and are not subject to the dangers inherent in being on, or moving around, tankers.

If the tank-to-pump and jet discharge valves are carried in the open position throughout the shuttle, no time is lost at the dump site. Once the tanker is positioned the operator engages the pump, opens the air valve and dump commences. Each department should determine the engine rpm needed for efficient dump and mark the cab tachometer with a line at that speed. After the operator engages the pump, the engine rpm is advanced with the accelerator to the point indicated on the tachometer.

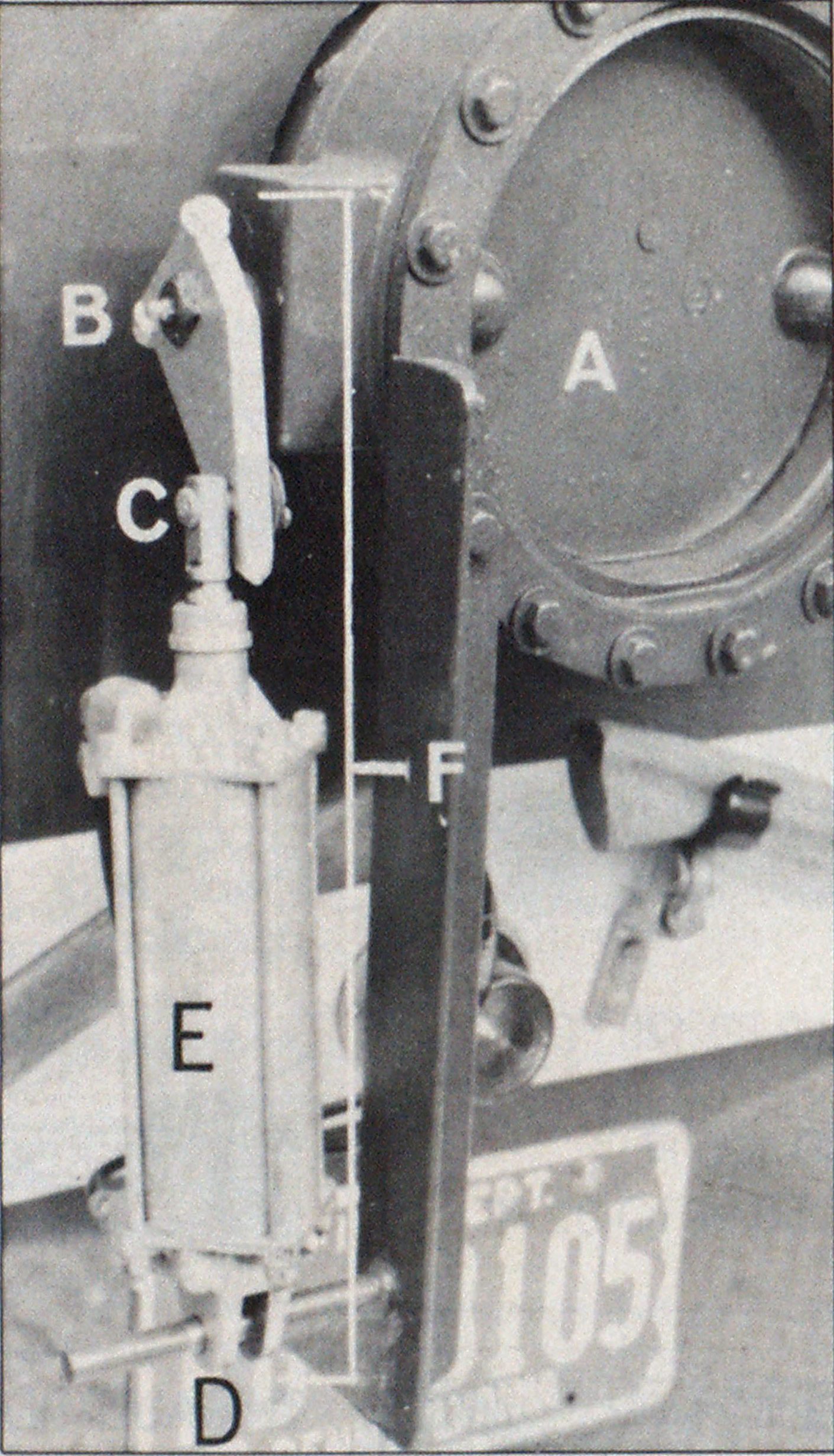

The basic components include a 2 by 6-inch two-way air solenoid, mounting hardware, air tubing and a two-way control valve. The parts are stock items used in the trucking industry for such applications as air-operated tailgates on dump trucks. The mounting hardware and linkage can easily be fabricated locally for the valve being adapted.

Use the main air cylinder on the tanker for the air supply to the control valve located in the cab. The lines that control the air solenoid are then run from the control valve to the rear of the tanker. If desired, a shutoff valve can be placed on the air line to the cab to isolate the system in the event of a malfunction.

When installing the air-operated dump, the preferred orientation of the butterfly is horizontal rather than vertical. Valves which open in the horizontal plane dump faster. This occurs because the butterfly is in line with the flow, which at dump velocities is laminar, or horizontally layered. Vertical valves are perpendicular to the flow and cause the water to split, thus creating turbulence which reduces dump efficiency.

Achieving flows in the 1000-gpm and above range is often difficult in a tanker operation. Adaptations such as the airoperated dump valve help cut vital seconds off tanker dumping and in turn help increase the available water supply. Also, for a total price of less than $300, safety is improved and the need for valuable manpower is reduced.

— photos by Randy watts, IFPA.