OIL ANALYSIS ALLOWS LONGER CHANGE INTERVALS

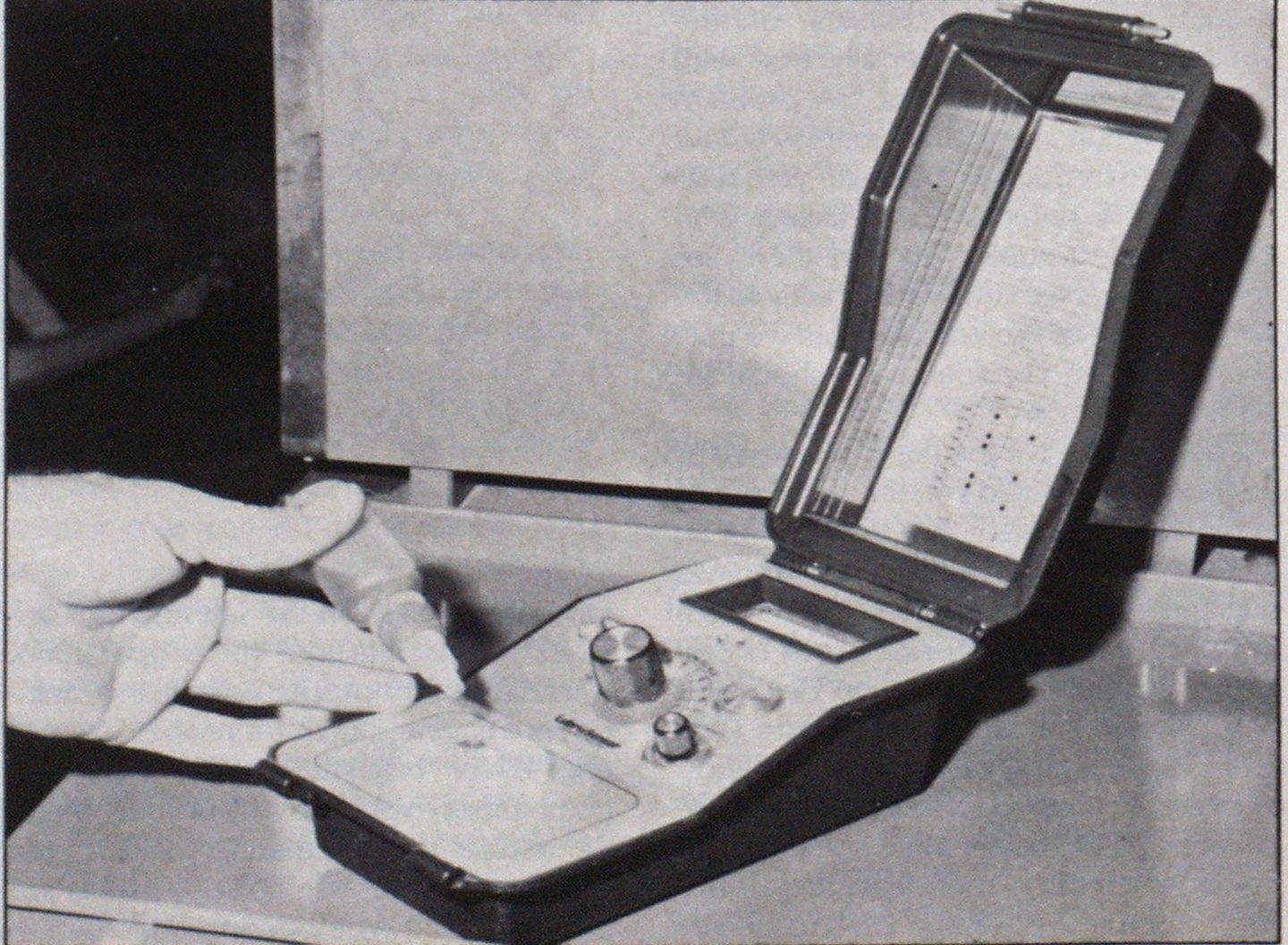

A simple, portable testing unit tells you more about oil condition than either mileage or length of time since the last change.

Two years ago. Fire Chief C. A. Shelton was interviewing applicants for the position of fire equipment mechanic when the mention of an “oil quality analyzer” caught his attention. The oil analyzer, being used in the maintenance program for a delivery truck fleet, could possibly be the answer to unnecessary, costly oil changes in fire service apparatus.

Further research, including assistance from Chief Chemist B.C. Hall of Sunoco Terminals, resulted in the purchase of a “Lubri-Sensor” oil quality analyzer for use in the Beaumont Fire Department fleet maintenance program.

Several years earlier, the Beaumont Fire Department had obtained a 15,000square-foot maintenance facility when the city bus maintenance operations were relocated. The vacated area was immediately renovated into a specialized mainte nance facility with three full-time mechanics for the repair and maintenance of emergency fire apparatus and equipment. Over 60 fire department vehicles are serviced at the shop, including 12 first-line pumpers, four aerial units, chief’s cars, numertxjs reserve units, and other specialized fire fighting and rescue apparatus

Permits longer intervals

The oil quality analyzer selected is a portable, battery-operated unit which requires no specialized or technical training to operate. Use of the oil analyzer allows fire department mechanics to determine whether oil is still usable, permitting longer intervals between oil changes, and lower operating costs.

The analyzer detects, measures and indicates the total effect of contamination on the dielectric constant of oil. As oil is used, its physical and electrochemical properties change in direct proportion to the type and amount of contamination present. A property change indicates a “change” in the lubricating capability of the oil. The lubricating capability of oil can be affected by contaminants such as water, oxidation, acids, etc.

The oil quality analyzer can be used for testing any petroleum-based oil, even synthetic oil, when samples of both used and unused oils are obtainable. The Lubri-Sensor can be used on gasoline or diesel engines, transmissions and compressor systems.

The Beaumont Fire Department uses the oil analyzer for testing oils and fluids in cars, pumpers, aerial apparatus, and even heavy machinery used at the fire training center, such as tractors, bulldozers, etc. In addition, the analyzer can be used for air compressors, generators and lawnmowers.

Simple operation

Although the analyzer is a sensitive instrument, operation is relatively simple. The quality reading of oil is obtained by making a comparison of unused and used oil of the same type. Three or four drops of unused oil are placed in the sensor cup, and the meter needle adjusted to zero. The sensor cavity is then cleaned and refilled with three or four drops of used oil. A sample of used oil can be obtained from the apparatus dipstick or by using a sampler tube. The meter needle will deviate in a direction (increase or decrease) of the change in the electrochemical property. The meter is again adjusted to zero. The scale reading indicates the amount of change.

The oil analyzer can detect various contaminants including acids, antifreeze, fuel soot, gasoline, diesel, metal particles, oxidation, sludge and water. Such con taminants not only affect the performance of the oil as a lubricant, but may also indicate impending mechanical failure.

— Beaumont Fire Department photos

Routine oil changes can often be delayed by testing the oil quality with the oil analyzer. As an engine operates, fuel soot and oxidation will gradually increase or build up in the lubricant. The increase can be monitored over a period of time, until a point is reached when the oil should be changed.

A more severe dielectric increase caused by water or acid requires immediate corrective action to avoid potentially serious problems. The source of the contaminant must be identified.

A decreasing dielectric effect may be caused by a contaminant such as gasoline. Immediate action must be taken to identify the source.

Before obtaining the oil analyzer, fire apparatus oil changes were done on a regular maintenance schedule. Chief’s cars, service trucks, vans, etc., were serviced (oil and filter changed) every three months. Other large fire apparatus were serviced every six months.

Mileage factor not reliable

Although the mileage factor could be used as a basis for oil changes in ordinary cars and trucks, mileage on large fire fighting apparatus does not indicate the actual hours the apparatus might have been in operation at a fire scene. For example, a pumper with relatively low mileage may have been used in pumping operations for many hours during an emergency. Until the oil analyzer was obtained, fire mechanics had no accurate method of determining the quality of the oil; therefore, many times oil was changed on schedule, but unnecessarily.

The cost factor in maintaining fire apparatus is excessive, not only considering the actual cost of large quantities of oil and filters, but also the labor involved and the apparatus downtime as well. Large fire fighting apparatus normally require 6 gallons of oil, plus a filter, and approximately three hours of valuable time the apparatus must be placed out of service.

With 11 fire stations, covering approximately 72 square miles of the city, apparatus were often driven 10 to 15 miles to the maintenance facility for routine servicing. This added further costs in fuel for trips to and from the stations. Most importantly, the apparatus were having to leave their territory in the process.

Apparatus stays in territory

With the portable oil analyzer, mechanics can go to the fire station (or any location) and test the oil quality. This leaves the apparatus in its territory and in service for emergency response.

Every three months, the oil analyzer is used to test the oil in all apparatus. Many times, the six-month scheduled oil change can be delayed. Most often, the oil life can be extended two to three times in vehicles that are infrequently used, such as the foam truck, diving van, light truck, etc.

The analyzer is also valuable as an aid in the immediate detection of impending major mechanical failure. Such analysis may provide advance warning of potential lubrication failure by detecting buildup or fuel dilution.

According to Shelton, the oil analyzer has not only saved money and labor costs for the department, it has also helped keep apparatus downtime to a minimum — keeping apparatus in its territory, ready to respond when needed. He added, “With the cost of fire apparatus today, proper maintenance is a must for all fire departments.”

For the Beaumont Fire Department, the oil quality analyzer practically paid for itself the first time it was used.