By Raul A. Angulo

One of the iconic symbols of the fire service is the pickhead fire ax. If you look at old black-and-white photographs of firefighters in action all the way up to the 1970s, many wore some sort of leather belt specifically to carry the pickhead ax by shoving the ax handle under the belt. In the late 70s and 80s, ax scabbards were becoming more popular. Today’s safety standards require them if you’re going to wear an ax. The blade and point must be covered with a scabbard. Within the last few years, personal axes with custom leather scabbards and belts have become extremely popular. Some of the leather work is quite exquisite and ornate. The problem is that, in addition to the weight of the ax, these wide leather belts and scabbards add a considerable amount of weight to the firefighter’s personal protective firefighting gear (PPE)–on top of the weight of the self-contained breathing apparatus (SCBA), the heaviest part of the full PPE ensemble.

RELATED: The Ins and Outs of the Halligan, Part 1 | Part 2 | Part 3 | Mike Ciampo: Truck Company Tools Across the Country

There’s a certain amount of pride in wearing a personal ax and scabbard – and the leather forever crowd demands that the belt and the scabbard need to be made from leather, not from synthetic material with Velcro fasteners. The same goes for classic suspenders – they have to be made from leather. However, all classic accessories need to be balanced with practicality and efficiency. Leather is not lightweight material, and since it absorbs moisture, the wetter it gets, the heavier it gets. I admit I fell into the leather-only crowd because that is what the old firefighters used to wear.

To accomplish this, I had to have a sequence of donning all my PPE so that it hung correctly and comfortably. For example, upon arrival at a fire scene, after putting on my coat, I had to don my leather belt with ax and scabbard before I donned my SCBA and buckled the waist strap. Doing it reverse was difficult: the ax head often caught on the coat tail under the SCBA waist strap or got tangled on the SCBA. Before jumping into my PPE gear, I was already well over 270 pounds. With full PPE, SCBA, and the ax with scabbard, I probably weighed more than 320 pounds. I still had to help carry equipment and climb ladders! By then, my knees and ankles were supporting 350 pounds if not more. As much as I tried to remain a traditionalist, I found that, the older I got, I was often willing to dump the extra weight just so I could actually do my job!

I tried attaching the scabbard to the waist strap of the SCBA unit, using that for the belt, but it was less than satisfactory – and then there’s the action of trying to get the ax out of the scabbard with one hand (it often required using two hands). The whole purpose of wearing an ax is to have it easily accessible at any given moment. Sometimes our safety standards regulate us into paralysis. Can you imagine if a carpenter had to have the claw end and the head of the framing hammer covered while wearing a tool belt and removing the cover every time he wanted to pound a nail? But those are the rules, and we have to work with the encumbrances they impose on us. Here is an alternative way to wear a pickhead ax without adding weight to the tool while still meeting the requirements of the safety standards.

Here’s what you need for this trick of the trade:

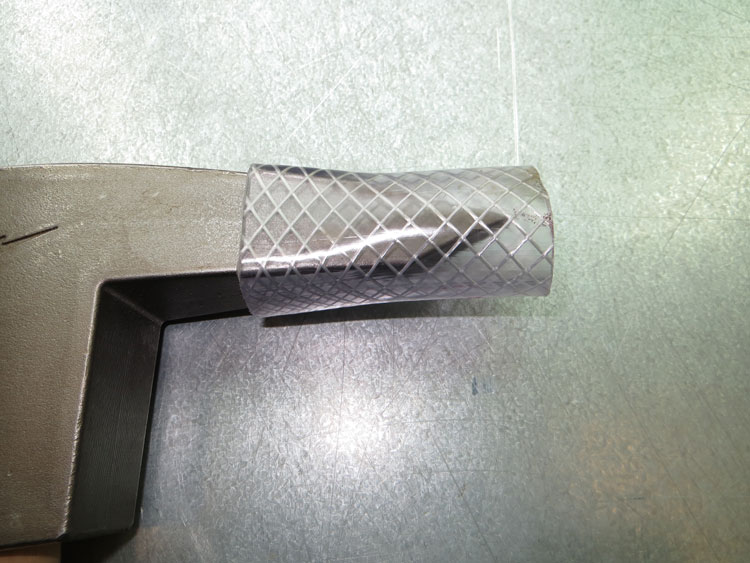

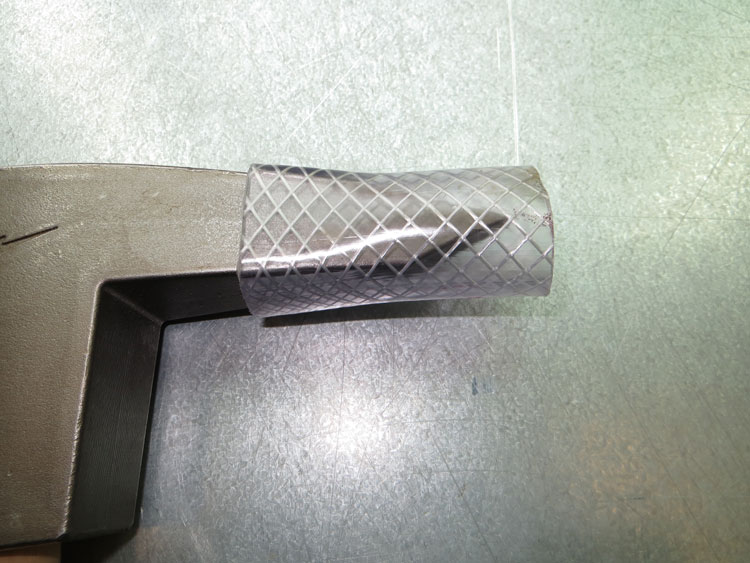

Some axes like the Iron Fox have a very thick blade – more like a wedge or a maul. Depending on the width of your ax blade and the thickness of the pick, get two feet of 3/4-inch or 1-inch clear industrial tubing. Then make a large rubber band from an innertube of a car tire. That’s it! (Photo 1)

Measure the curve of the ax blade and cut the appropriate piece of clear tubing. Cut a single slice along the length of the tubing. Don’t cut it in half. Fit the tubing over the length of the blade. The natural tension in the tubing will hold it in place until you can secure it firmly with the rubber band. (Photo 2)

Put a second piece of tubing to fit snugly over the pick end. It needs to extend beyond the point for safety. Don’t force the tubing down so tight around the pick that it makes it difficult to remove. Cut two notches at one end of the tubing to accommodate the rubber band so it won’t slip off. (Photo 3)

That’s it! The ax is now compliant with safety regulations because all sharp edges and points are covered while still showing off the craftsmanship of the ax. The handle can be slipped through the SCBA waist strap and you’re ready to go to work without the added weight of a leather belt and scabbard. (Photo 4)

This trick of the trade can be modified for modern fire ax technology. For example, the Wonderboy Fire Axe by Clint Bowring has a flat edge blade. It’s more for smashing and demolition of lightweight construction than it is for cutting and chopping. There is a sharp point at the bottom of the blade and a sharp ended pick like the traditional fire ax. The safety standards would require these points to be covered.

In this case, there’s no chance of cutting yourself along the blade so that can be ignored. Cut a two-inch piece of tubing and drill one hole into the membrane of the tubing large enough to cover the point on the blade end. Thread the rubber band through the tubing. You’re basically creating a cushion to cover the point. (Photo 5)

Push the point of the blade into the hole until it’s snug. Then pull the rubberband over the top of the blade to hold the plastic cushion firmly in place. The pick end of the ax can be covered as before in the previous example. Make sure the tubing extends beyond the point of the pick. (Photo 6 and 7)

The ax is ready to insert into the SCBA waist strap and the safety standard has been met. These are just two examples of how to wear your ax and comply with the safety standard. There are other configurations I’m sure. The objective is to cover the sharp edges and points that can cause personal injury in case you trip or fall. The other objective is to have your best tools readily available for immediate use. The third objective is to reduce the total amount of weight you’re carrying.

When you’re on the fireground and you need your ax, you can pull it out of the waist strap and quickly flick these covers with a gloved hand. If you have time, you can toss them in a corner and retrieve them later, or you can hunt them down after the fire. If you can’t find them, you can quickly make a replace set – that’s why you buy the extra tubing. This is an effective, inexpensive substitute for heavy, cumbersome leather belts and scabbards. The weight issue may not be a big deal when you’re a young-buck firefighter in tip-top shape, but after you’ve been riding fire trucks for over 35 years and your ankles and knees are shot after years of fireground abuse, you’ll be amazed how quickly you become a fan of lightweight tools and equipment. Anything to lighten the load on your body will go a long way to extend the longevity of your career. Trust me, I’m paying the price today for years of cumulative physical damage.

Drills You Won’t Find in the Books: Class A Foam

Drills You Won’t Find in the Books: Bangor Ladder Rescue for H-Shaped Buildings

Drills You Won’t Find in the Books: Stokes Snow Sled Drill

Drills You Won’t Find in the Books: Kid Stuck in a Tree

Drills You Won’t Find in the Books: The Dancing PPV Fan Drill

RAUL A. ANGULO retired from the Seattle (WA) Fire Department after more than 37 years of service and is also Captain Emeritus of Ladder Co. 6. He is a featured author and a member of the Editorial Advisory Board for Fire Apparatus and Emergency Equipment magazine and is a regular contributor to Fireengineering.com with “Drills You Won’t Find in the Books.”

RAUL A. ANGULO retired from the Seattle (WA) Fire Department after more than 37 years of service and is also Captain Emeritus of Ladder Co. 6. He is a featured author and a member of the Editorial Advisory Board for Fire Apparatus and Emergency Equipment magazine and is a regular contributor to Fireengineering.com with “Drills You Won’t Find in the Books.”