Special Supply Method Gets Credit for Extra Hydrants

Rural/Metro Fire Department of Scottsdale, Ariz., was able to prove a point of water supply during a rating visit by the Insurance Services Office (ISO). In turn, the community received credit for 160 more hydrants than it actually had.

Credit for the “phantom” hydrants was achieved by using 4-inch fire hose, a “portable hydrant” and a special pumper with a drop-off pump. The fire department demonstrated that it was possible to deliver adequate water at a distance twice as great as implied by normal fire hydrant spacing in residential areas of required 1000-gpm fire flows.

The 160 hydrants represented credit for about 9 percent more hydrants than the approximately 1775 hydrants the community actually had at the time of the grading. They produced about 40 net additional points on the grading, or 8 percent of a class.

Contract department

Fire protection in Scottsdale is a contract service of Rural/Metro Fire Department, Inc., which serves some 20 percent of the State of Arizona’s population. At the time of the ISO grading, we presented the following concept.

Only 1000 gpm is required in most of Scottsdale’s residential area. Standard hydrant spacing is based primarily on a presumption of 2 ½-inch hose technology. In Scottsdale all first-out apparatus and much second-response equipment carries 4-inch hose with adapters to use it. Thousands of feet of 4-inch hose with the necessary fittings and automatic hydrant openers have been purchased to make this technology feasible.

Rural/Metro believes the use of even one line of 4-inch hose makes it possible—with the same manpower and without loss of time—to meet 1000-gpm fire flows at twice the normal distance for a hydrant.

ISO represented in this portion of the grading by Gene Nelson of its San Francisco office, in effect said, “Prove it and we’ll buy it.” As a consequence an afternoon of hose-laying and pumping was scheduled. With variations called for by Nelson (and one interruption for a fire), the experiments continued until after dark that day. The evolutions demonstrated the capability of the department to pump in excess of 1000 gpm through one 4-inch line 700 feet from a hydrant.

Three tests

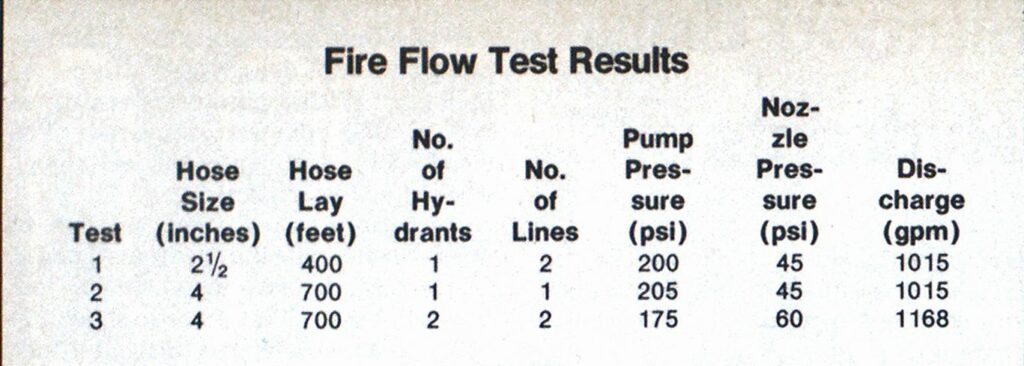

Three evolutions were of primary importance. Test 1 (shown in accompanying table) was simply a verification of conventional technique. Two lines of 2 1/2-inch hose were laid 400 feet and we pumped into a deluge gun with a 2 ¼-inch tip. With a pumper operating at 200 psi, 1015 gpm were delivered. The conclusion: Conventional technology worked just as expected.

Evolutions were then created to demonstrate two alternative methods of delivering adequate water at 700 feet instead of 400. Test 2 was to show that water could be delivered with one 4-inch line through 700 feet of hose as compared to the first test’s two 2 ½-inch lines 400 feet in length. For this test one 4-inch line was pumped at the hydrant into the same deluge gun with the same 2 ¼-inch tip. Delivery was again 1015 gpm. A pump pressure of 205 psi was required, compared to 200 psi in Test 1. The second conclusion: One 4-inch line does the job.

A final demonstration, Test 3 in the table, was conducted to use Scottsdale’s “tailgate pumper.” This is a pumper with a conventional pump mounted midship plus a portable unit mounted on a forklift at the rear of the truck. This makes it possible for the unit to pump two lines—one from a hydrant used by the tailgate unit and another used by the midship pump. In effect this one pumper does the job of two.

Portable hydrants used

For this test two 700-foot lines were laid, one from each of two different hydrants. They were laid in to a commercially produced portable hydrant consisting of two 4-inch inlets and four 2 ½-inch discharges. From this portable hydrant, two 2 ½-inch lines were stretched into the same deluge gun. Pump pressure this time was only 175 psi, yet 1168 gpm was produced. Obviously, at pump pressures equivalent to those in Tests 1 and 2, more water could have been pumped. The conclusion; Water flow much in excess of the required 1000 gpm is obviously available by this technique. Pump pressure required in Test 3 was 15 percent less and water supply 15 percent more!

There are a number of implications to the procedures used and their acceptance by ISO. At the time of the Scottsdale grading, under the old ISO schedule, credit was given only in residential areas of 1000-gpm fire flow. The department believes that, under the new schedule, credit for an additional 90 hydrants could be picked up in nonresidential areas.

The economic impact is obviously major. If another 160 fire hydrants actually had to be installed in the City of Scottsdale, they would cost between $128,000 and $160,000. Further, maintenance would be about $6400 per year. Finally, and of most importance economically: Spacing at greater distances would permit down-sizing the mains installed in the water system.

The technique is eminently transferable. Any community using large diameter hose properly with the proper Fittings could do the job. While the tailgate pumper used in Scottsdale probably saves time and manpower, two conventional pumpers could meet the requirements of Test 3 and one could meet those of Test 2.