PROPANE Problems Addressed through Training

FEATURES

TRAINING

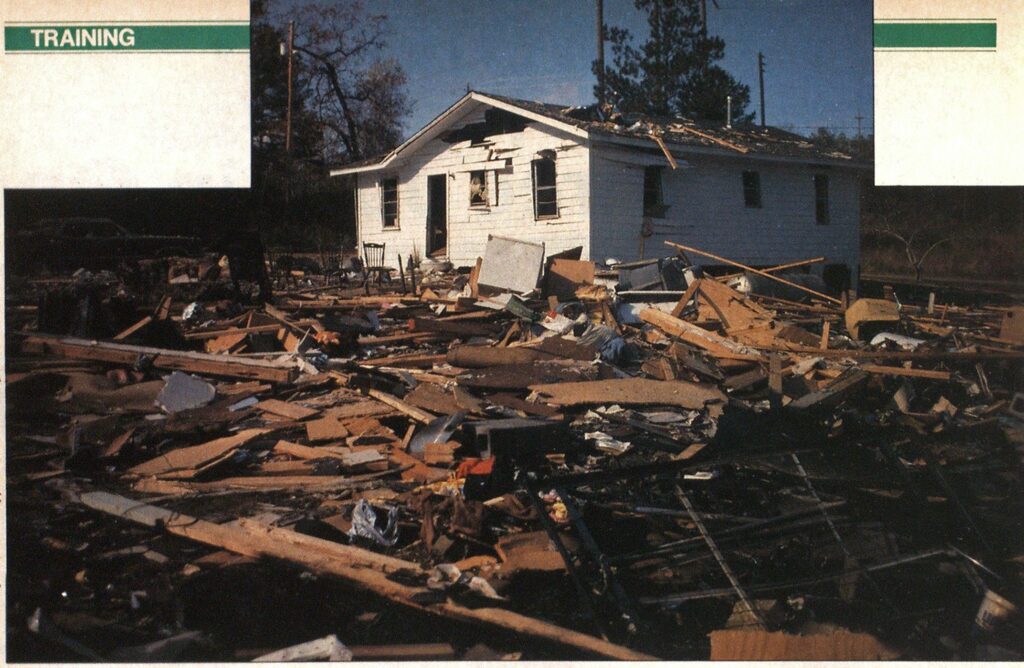

Photo curtesy of the Mississippi State Fire Academy

A liquefied petroleum gas (LPG) explosion that occurred in Whitefish, MT, was the topic of discussion in the hazardous materials course at the Mississippi Fire Academy in Jackson last December 4.

Shortly after the class adjourned, another LPG explosion occurred— two miles from the academy in Pearl, MS.

The explosion, which was felt more than five miles away and heard twenty miles away, brought two engines and Chief Robert Trigg to the scene. They found debris scattered over a large area and a heavy fire condition in the vicinity where a three-bedroom residence once stood. Stretching two 1 1/2inch preconnected handlines, the firefighters extinguished the fire without much difficulty.

The explosion also irreparably damaged two residences, one 30 feet away and another 100 feet away. Other structures, some a mile or more from the incident scene, received varying degrees of damage.

Miraculously, there was only one minor injury sustained by the resident 30 feet from the explosion site.

An investigation pointed to the probable cause of the incident being a faulty furnace, which was supplied by an above-ground 500-gallon propane tank located 50 feet from the house. The faulty valve allowed propane to escape for a period of eight to nine hours during the day. Early that morning, the occupant had tried unsuccessfully to light the furnace. The probable cause of ignition was determined to be the television. In many areas of the country, propane is considered an alternate fuel source. However, in Mississippi, propane can be considered an essential fuel source. Because it is easily stored and transported, we expect to see an ever-increasing use of propane. Unfortunately, with its increased use, people begin to lose respect for the product.

Fire officers responding to a propane leak may encounter two basic tactical problems:

- Leaks with no fire;Leaks with fire. (Propane’s flame temperatures may exceed 2,000°F)

In the case of leaks with no fire, the most immediate problem is the vapor, which is heavier than air (1.5 vapor density). Officers must remember that the vapors may be invisible, and in some industrial applications there may have been no odorizing agent added to the product. Vapors must be considered as if they were water, meaning that they will flow with the slope of the land unless the wind is strong enough to move them in a different direction.

If it’s a no fire situation and there is a liquid leak, the vapor cloud will appear as a fog cloud due to frozen moisture in the air given off by the propane, which is a refrigerant. Due to the expansion ratio (270 parts gas to 1 part liquid), the problem is greatly increased with a liquid leak. The only way to safely determine where the gas is located is with an explosimeter. Without the proper detector, this problem may be the same as if the firefighter were walking through a mine field without a mine detector.

It’s obvious that evacuation procedures must be initiated immediately. The size of the leak and the potential for explosion should determine the evacuation distance. Exploding railroad tank cars have rocketed debris over 3,000 feet, and radiated heat has injured bystanders who were over 1,000 feet from the point of explosion.

In addition to the size of the leak, the officer must consider the size of the vessel involved, wind direction and velocity, slope of the land, population of the area, and probabilities of ignition. I recommend a minimum evacuation of 1,000 feet for every 10,000 gallons of tank capacity.

The most obvious way to control leaks both with and without fire is by closing a valve to stop the fuel flow. However, this should only be performed with the protection cover of water spray (fog stream), full protective clothing, and selfcontained breathing apparatus.

Leaks with fire where the flames are impinging on the vapor area of the vessel may weaken the shell to a point of rupture, commonly called a boiling liquid expanding vapor explosion or BLEVE. Regardless of the situation, the fire officer must remember never to endanger personnel or equipment needlessly.

The Mississippi Fire Academy’s approach to live fire training for gas emergencies begins with classroom instruction on the physical properties, and the tools and equipment associated with the transfer and use of propane fires.

Tactical problems and hands-on training are then addressed in two live fire situations. The first training exercise consists of a vertical pipe with cross pipes commonly called the “Christmas tree.” Students are briefed on the fireground area, the overall strategy and tactics, individual assignments, position of team members, position of instructors, and the nozzles’ angles to the Christmas tree. All students are required to wear full protective clothing which must include faceshield and leather gloves.

Photos courtesy ot the Mississippi State Fire Academy

An attack team consists of six students; there is also a team leader, safety officer, an officer assigned control of the safety valve and three students and an officer on the backup safety line. The attack team advances with two 1 3/4-inch handlines flowing 200 gpm on a full fog. The safety team also advances with a charged line to the right side of the attack lines. Once the attack lines are within 30 inches of the Christmas tree and the nozzles are in proper position, the manual propane valve at the base of the tree is closed by one member of the attack team. When the tree is properly cooled, both teams back out under the protection of their fog streams.

The second live burn situation consists of a 250-gallon cutaway propane tank. The tank is piped in a manner where the instructor at the safety valve can maintain control of both the burner under the tank and the relief valve. Again, we use the same configuration of attack team members. Once the burner is ignited, the relief valve is opened. At that point, one attack line is placed on straight stream, cooling the vapor area of the tank. The other line is placed on full fog for personnel protection. After the safety valve officer has determined that the vapor area of the tank has been cooled sufficiently, he shuts off its fuel supply. However, if the attack team fails to keep cooling water on the vapor area, the relief valve will be reopened.

photo courtesy of the Mississippi State Fire Academy

Once in the proper position at the tank, the attack line nozzles will be about 2° to 15° below horizontal. With nozzles in this position, the team officer can reach the shut-off valve located on the top of the tank. With the valve closed, back out procedures are essentially the same as with the tree.

Flammable compressed gases, when released uncontrolled, have the potential to set off explosions of devastating proportions. And with the increased use of propane for home fueling, it’s imperative that all fire departments and emergency services train their personnel in dealing with the hazards associated with these gases.