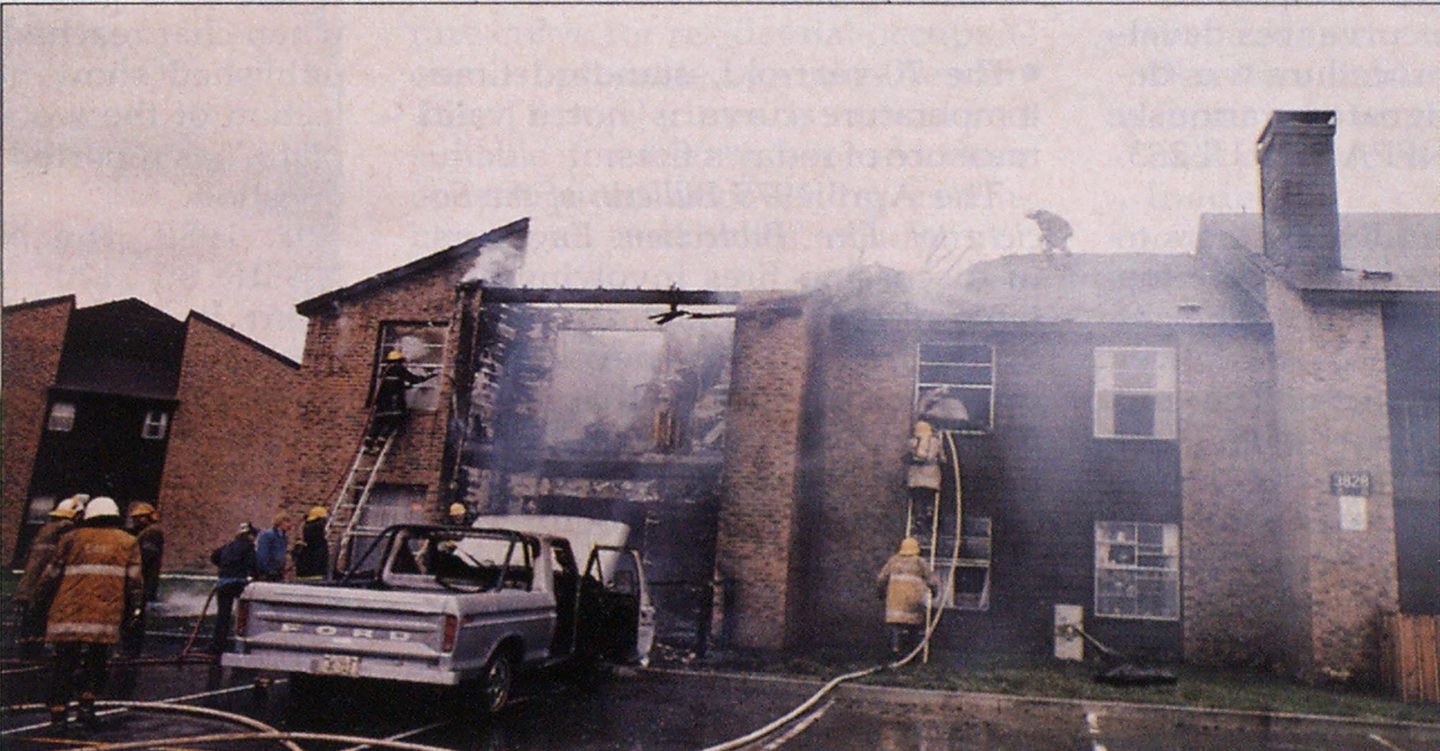

Are Wood Trusses Good for Your Health?

BUILDING CONSTRUCTION

(All photos by Francis L. Brannigan, except as noted.)

The safety issue of lightweight wood truss floor assemblies provokes controversy.

A national fire service publication recently published an artide concerning the performance of wood truss floors during a fire. Its purpose was to allay firefighters’ fears about the collapse potential of these floors.

The article was written by an official of Wood Products Research for the Forest Products Laboratory of the U.S. Department of Agriculture. The laboratory’s stated mandate is “to explore the field of wood utilization for the benefit of the people and for the perpetuation of the resource— Surer predictions of fire behavior and better treatments for fire resistance will alleviate a long-standing concern in the use of wood based materials.’

The ASTM E119 fire endurance test

The premise of the article relies principally on tests conducted in accordance with the American Sodety for Testing and Materials’ El 19, the standard fire-resistance test. There is a real question whether the ASTM El 19 test is legitimate when used to determine the fire resistance of wooden structures.

In the early 1900s, “fireproof” buildings were designed according to the whim of the architect. In 1908, New York’s Parker Building burned and collapsed. It had been thought to be the best type of fireproof mercantile building. Its loss was considered by fire protection engineers to be very serious. It was obvious that a standard definition of “fireproof” was needed.

In a remarkably short time, all concerned organizations—the National Bureau of Standards (NBS) Underwriters Laboratories (UL), the National Fire Protection Association (NFPA), and insurance organizations, both capital stock and mutual —pooled their resources. The standard fire curve was developed and a test procedure was designed (and designated variously as ASTM El 19, NFPA 251, UL263, and ANSI A2.1).

The procedure calls for floors to be tested by being built as the top of a 14by 17-foot furnace. The gas fire below is regulated to deliver the standard fire curve. The end point is reached when the floor deflects excessively, the temperature on the top side passes certain points, or the floor collapses.

When this test was developed the tested floors were of noncombustible brick or hollow tile. It made sense to test the floor only one way: from underneath.

Years ago, when the question came up about the validity of applying this test to combustible floors, tests were made at NBS which demonstrated that floor temperatures observed were not fire-significant, that is, were not high enough to ignite the floor.

Listings of floor assemblies with wooden components that passed the ASTM El 19 test were listed in UL’s Fire Resistance Directory as “fire resistive-combustible.” Recently, the word “combustible” has disappeared from the listing. Despite this change, the most significant characteristic of such assemblies is their combustibility.

When I first realized that ordi\j nary apartment house fires T T were burning down into the floor void early into the fire, and reported this in “A Field Study of N on -Fi re-Resis ta n t Multiple Dwelling Fires” for NBS, one researcher exclaimed, “The fire is not supposed to burn that way!” I answered him by saying, “Who put you in charge of how the fire burns?” The essence of the answer is that test procedures should be realistic representations of actual fire conditions if the results are to be cited by organizations as reassurances to firefighters.

Does ASTM El 19 do this in the case of wooden floors of any kind? I think not, certainly not to such a degree as to reassure firefighters about collapse potential. My reasons are as follows:

- The 70-year-old, standard timetemperature curve is not a valid measure of today’s fires.

The April 1975 Bulletin of the Society of Fire Protection Engineers, in discussing fires involving contents of today’s buildings, states, “…the rate of fire development can create a condition that may tax or overpower traditional fire defenses.”

In 1985, the NFPA produced the remarkable film, “Fire, Countdown to Disaster.” It shows the rapid growth of a typical, very ordinary bedroom fire. In two minutes and twelve seconds, flashover had occurred and floor temperatures were 450°F. The carpeting was burning. Thirty seconds later, the temperature exceeded 1230°F everywhere in the room.

Battalion Chief John Mittendorf has reported on some nonstandard tests on unprotected, lightweight roofs conducted by the Los Angeles City Fire Department. The test materials were cut-up wooden pallets. The fire was ignited by four gallons of thinner. The test structures carried no superimposed load (a bias in favor of the structure). The trusses spanned 30 feet. They failed in 1 minute, 30 seconds. The gusset plate fell out when char reached ¼”. The photos published show no sign of “protection of the wood by the gusset plate,” as reported by the article in question.

In 1980, the NBS published NBSIR 80-2120: “Fire Development in Residential Basement Rooms.” Don’t be misled by the specificity of the title. The rooms were typical living rooms or office reception rooms. The report yielded significant photos of a typical room in which fires were ignited in newspaper spread over the back of a couch. In less than four minutes, fire is seen pouring out of the full doorway.

The report indicates heat fluxes at the floor level in the range of 100 to 160 kw/m2 between the time period from 6 minutes until 12 minutes. (See Graph A.) I understand that this energy level is sufficient to ignite a wooden floor.

Graph B shows a comparison of the fire exposure curve derived from Test 9 with the ASTM standard curve. The test curve peaks at over 1000°C (over 1800°F) in ten minutes.

The NBS report has this to say about ASTM El 19 and Test 9:

“The rate of development and intensity of real fires involving the burning of tvpical furniture and interior linings in a room during the first 20 minutes may be significantly greater than those defined by the ASTM El 19 standard timetemperature curve.

A more realistic time-temperature curve for residential occupancies is presented in this report. This [Test 9] curve is considered suitable for testing exposed floor construction, floor-ceiling assemblies, wall assemblies, columns or doors.”

Readers are urged to write the NBS for the full report.1

- The ASTM El 19 test is conducted on a tightly firestopped structure measuring 14 feet x 17 feet. This cannot be regarded as representative of structures as built.

- The test does not simulate the possibility of a fire entering the truss void from the flooring. Yet, the NFPA tape/film, “Firepower,” clearly shows dripping and pooling plastic fire from a couch burning on the floor.

- The test does not simulate fire entering the truss void laterally, such as:

The test structure is built by the organization sponsoring the test. In light of this, it is safe to assume that the test structure is the best that can be built, not the typical or average structure.

The typical structure may have many structural defects. Some are detailed in “Failures, Wood Truss Roof,” Progressive Architecture, Oct. ’86, page 57. In a collapse of a truss roof under construction, some of the defects noted were:

“Use of lumber of inadequate dimension at joints where forces2 were high.

Knots located in gusset plate contact area.

Gusset plates not centered on several joints.

Gusset plate lugs not adequately embedded in the lumber.

Defective lumber used. Attempt to repair split lumber with a plate.

Lack of fit-up at truss end.

Inadequate connector sizes. Poor fit up of joint. Reduced lumber section at joint due to improper finishing.”

Of course, these refer only to _____ tion which exists in the building materials supply business and the fact that trusses are unseen by the purchaser or renter provide every incentive for the builder to go with the cheapest supplier.

The size of the test structure is not realistic. The truss void might contain 238 cubic feet of air, which would contain about 50 cubic feet of oxygen. (One cubic foot of oxygen will support combustion that can give off 537 BTU before it is consumed.) 50 cubic feet would therefore generate a maximum of 27,000 BTU, which would be provided by about 3 ½ pounds of wood. The burning of the wood of the trusses is therefore self-limiting until the ceiling opens up to admit more air. A realistic structure would be about 1200 square feet (the size of an average apartment). A greater amount of oxygen would then be available to support combustion.

A realistic test structure would provide additional air to represent the air that would be available through the alleged firestopping.

1 Not long after this report appeared, the Reagan Administration’s Office of Management and Budget attempted to zero-fund fire research for NBS, alleging that private industry should do the job. The united opposition of the fire protection community defeated this proposed action, but the administration’s attitude toward NBS fire research greatly hampers the organization’s recruiting of bright, new talent.

2 Editor’s note: “Forces” in this case refers to physical forces on the structure.

by an exterior fire burning through the combustible exterior into the truss void.

by fire passing through or around the firestopping.

Such conditions totally negate the “protection” provided by the gypsum ceiling.

A most serious threat to life safety by lateral extension is set up when the trusses are extended out (either as cantilevers or continuous beams) to support a balcony which is the exit for the occupants and the access for the fire department. Where the truss passes over the exterior wall, firestopping in the form of a sheet of gypsum board is “buttered into place.” This firestopping must be penetrated for the lighting circuits of the balcony. In any event, the use of such an unreliable barrier to prevent the extension of fire from the void is inexcusable. The potential for a disaster should force a code requirement that the exit facilities be totally separated from the truss void.

In some cases the ceiling of the balcony exit is plywood, permitting early access to the void for fire coming out of the window below.

- The test does not provide for any penetrations of the gypsum sheath. Light fixtures, HVAC outlets, and ventilating duct inlets are typical of “pinholes” which penetrate the gypsum sheath. Fire can be directly delivered to the void by metal air vent ducts from interior kitchens or bathrooms without windows.

- The test does not simulate fires which initiate in the void, as from wiring or metal chimney ducts.

- If the test results are to be used to reassure firefighters, it would appear reasonable that, in addition to the static live load, there should be a moving live load with some impact component representing two firefighters making a primary search for victims. Two firefighters carrying modern, lightweight selfcontained breathing apparatus and the minimum tools used for a search weigh 475 lbs.

- The article speaks of gusset plates protecting the underlying wood. There is evidence to the contrary. Just as steel pins are used to carry heat into baking potatoes, so do steel pins used in wood and tubular steel trusses bum the wood from the inside.

- All comparative-strength controversy aside, the joisted floor has one tremendous advantage over the truss. Each joist acts as a fire stop. The area of the void is limited. The truss void, on the other other hand, represents a huge area in which explosive carbon monoxide (CO) can accumulate. In the usual case, the CO in a combustible void deflagrates and we experience the dreaded backdraft or smoke explosion. In rare cases, the stoichiometric mixture is reached and the CO detonates. This has been enough to bring down masonry walls.

- Steel girders are being used with increasing frequency as main structural elements. Apparently the building officials believe that the gypsum sheathing also protects the steel. This is simply unevaluated. The steel is exposed to fire in the void, and the elongating steel, if restrained, will rotate on its axis —that is, overturn —and dump the wood trusses.

The use of trusses provides a huge increase in the volume of concealed voids in the structure. The voids are almost invariably interconnected by utility pathways. Firestopping, even if installed, is rendered ineffective by maintenance work or by new installations, such as cable television.

By no means should anyone assume that this article is in praise of sawed wood joists. They have stood up to many fires, but many firefighters have lost their lives on joisted floors.

There are no fire-resistive roof assemblies. The article in question reports on a test in England in which the roof was protected by gypsum 12 inches thick and insulation 2 inches thick. (It would appear reasonable that the numbers were reversed; twelve inches of gypsum would be an extremely heavy load.) Was the weight of 2″ of gypsum calculated into the design of the truss bottom chord, which is now subjected to serious bending (tension and compression) stresses? The weight of panels of gypsum 2″ thick would be a serious hazard to firefighters operating on the top floor, when the roof truss from which they would hang was weakened, or the nails pulled out.

Even if such an assembly were approved, the fact is that most fires reach the roof via interior plumbing voids or outside extension through the attic vents. A proposal to locate vents off the line of the windows to minimize direct flame access to the attic was presented at the Building Officials and Code Administrators International (BOCA) code meeting in Virginia Beach in 1980. This simple, costfree change was soundly defeated.

It would be much better to lay the 2“ of gypsum over the top of the stairway, supported from below, to make the stairway a place of refuge, so that the attic trusses will not fall on the escaping tenants and the arriving firefighters.

Why such an article?

The article in question appears to be another attempt by persons in the various industries which supply building materials to hush up firefighters and stop them from interfering with their business interests. There have been many such attempts.

Case in point: One of the outstanding figures in the fire protection field is Percy (Perk) Bugbee, longtime general manager of NFPA. In Men Against Fire—The Story of NFPA, 1896-1971, he describes the all-out efforts of the lumber and shingle interests to defeat any prohibition of w^ood shingles, despite their often demonstrated conflagration potential.

Case in point: When the hazard of combustible fiberboard first came to light, the manufacturers seemed to have representatives at every meeting to attack any effort to restrict its use. I can testify personally to this. In April 1949, a terrible fire occurred in St. Anthony’s hospital in Effingham, Ill. A key element was the spread of fire on combustible ceiling tile. Even in the face of this fire the industry was adamant. The tile manufacturer was sued by the hospital. The substantial settlement was sealed by the court, but thereafter the industry decided that it would be better to cooperate in developing standards.

Case in point: When the Washington D.C. area subway was being built, there was concern about the negative comments by fire officers on the use of plastics in the subway. One member of the Metro Board said in an open meeting that the members should go back to their respective jurisdictions and tell the fire chiefs who they work for.

Case in point: In the March 1980 issue of Fire Engineering the editor, Dick Sylvia, a fire officer and fire science lecturer, wrote an article about truss construction entitled, “New Types of Construction.” It made two major points: (1) The dangers associated with rapid flame spread would be lessened by firestopping and by education of architects. (2) Firestopping as constructed is a farce. This triggered a negative industry response in a letter from a representative of the National Forest Products Association published that June.

Remedies

Frankly, I don’t see any real improvement in the situation. Most buildings never burn, so an argument from the standpoint of “our local experience” can be used effectively on our politicians.

Code changes requiring separation of the exit facilities from the truss voids and requiring adequate protection for the tops of stairways might succeed in some locations.

It might be possible to persuade some designers that “I met the code” is not necessarily an effective defense in a negligence lawsuit.

Firefighters should be fully informed about the fire protection defects of truss voids. We must learn to “undress the building” and see the hidden fire paths.

The limited-area sprinkler systems being installed in combustible multiple dwellings will surely extinguish a great percentage of the fires. They will not reach a fire which originates in or penetrates the void.

In the past, I have offered one really wild idea. Suppose very high-temperature heads were located at strategic points in the void. When the head yielded, the high temperature would flash the water to steam. This might suppress flaming in the void until the steam dissipated.

Let’s not be too quick to accept the claims of all those who would put our fears to rest, no matter how well-intentioned they may be. When it comes down to people’s lives, we can never be too certain without first seeing the whole picture and getting all the facts. Many erroneous conclusions have been drawn from obsolete test procedures. Let’s not allow it to happen in the case of wood truss floor assemblies—or any other building material in the firefighter’s workplace.