Photos and incident report from Jeremy Rifflard

On March 19, 2018, a distracted driver of a pickup truck drove off a primary Road (Lone Oak Road/U.S. Highway 45) in Paducah, Kentucky. The driver started choking while driving and may lost consciousness to some extent, however he did not take his foot off the gas pedal. According to police, the driver drifted into the left lane on Lone Oak Road, hit a SUV, then continued across the parking lot of Banks Market. Here he hit a utility pole, broke a utility power box, struck a car, then crossed Maryland Street and drove into the vacant Music Zone building. The truck continued through the building, going through one interior wall and three load-bearing walls before it came to a halt 30 feet inside the vacant music store under a load-bearing beam that connected two roof systems.

(1-2) A pickup truck traveled 30 feet into the vacant music store coming to rest under a load-bearing wall that it damaged.

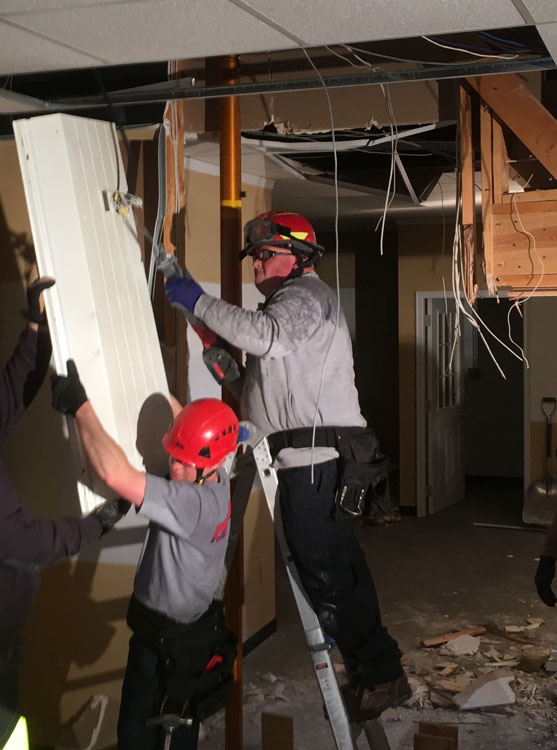

(3) Rescuers cut damaged wall sections to expose the structural members that will be shored.

(4) Rescuers widen a path to pull the truck out of the building without striking the remaining walls.

Engine 4, Engine 3, Ladder 7 and Rescue 2 were dispatched. Engine 4 was the first-arriving unit. Captain Todd Warner along with Engine 3 crew quickly made a life safety assessment of this building and called for additional resources. The pickup driver had his injuries treated and was removed from the structure. After assessment, he was transported to the hospital to receive further medical care. The utilities and gas were shut off to the building. A hasty search was made to confirm that no other people were inside the vacant store. The battery of the pickup truck was disconnected. No engine fluids or fuel were leaking from the vehicle. As a safety precaution, several portable fire extinguishers were staged near the truck. Portable lighting was brought inside the business.

RELATED: Simple Technique for Constructing Shores for Sloped Floors | The Importance of Training for ‘Rare’ Incidents

Jody Burton , Paducah captain of the technical rescue team, responded to the incident on Ladder 7 along with Deputy Chief Matthew Tinsley and Battalion Chief of Training Ronald Rathman. Deputy Chief Tinsley made the decision to call out the technical rescue team (TRT), the assistant fire marshal, Chief Steve Kyle, and a building inspector to assess the damage of the structure.

Ladder 7 and Rescue 2 are technical rescue-trained firefighters. Twelve students from Paducah and Murray, Kentucky, were in a structural collapse technician (SCT) shoring course being delivered just a few miles away inside the city limits of Paducah. Command staff decided to enhance the number of technical rescue firefighters by having the students respond along with the SCT instructors from Technical Rescue Training LLC to assess the damage and develop a shoring plan.

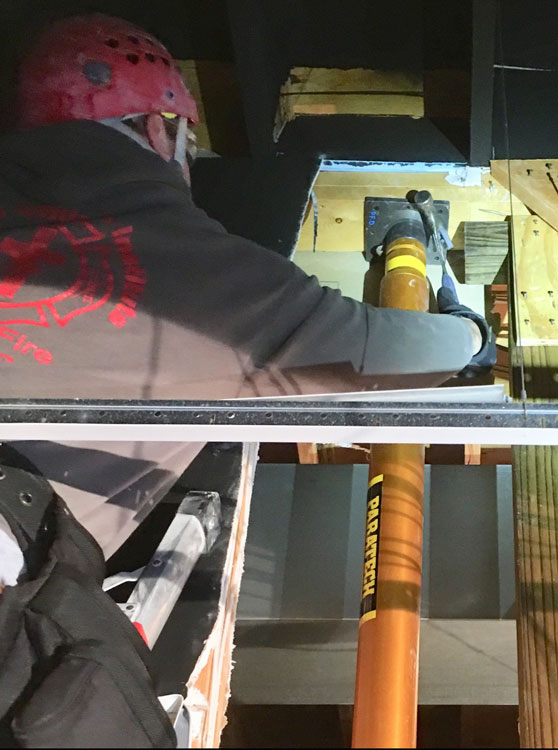

The building inspector was concerned about the damage to the third load-bearing wall where the truck came to rest. The responders developed a shoring plan to immediately install a pneumatic shore extending from the concrete floor, clearing away a suspended nine-foot drop ceiling, to the header, which was just less than 13 feet in height. The plan called for additional shores to be installed after the pickup truck was moved from under the load-bearing header. This is where the technical rescue team would construct and install a two-post vertical shore and attach it to the wood girder. Because of the tall height of the shore, it would require two midpoint braces.

(5) Firefighters install a pneumatic shore next to the pickup truck.

(6) The Paducah Technical Rescue Team installs a two-post vertical shore.

In addition, a large portion of damaged non-load-bearing wall that inspectors would pass under was be stabilized with a Spot T Shore. All the shores were constructed according to the U.S. Army Corps of Engineers (USACE), Urban Search and Rescue Shoring Operations Guide (SOG) guidelines.

Several tasks were identified and simultaneously completed. While a squad of four technical rescue firefighters prepared a pneumatic shore, two squads of firefighters began removing debris on the floor, cutting broken wooden studs flush with the load-bearing header and widening a path for the vehicle to be pulled out of the building. Under the supervision of inspectors, firefighters cleared the path, which included cutting wooden and drywall load-bearing and non-load-bearing walls of the building. This was to slightly widen the exit so that the movement of the vehicle would not strike the remaining portion of the wall.

The exterior load-bearing wall was metal paneling over 2×6 wood studs with insulation and interior drywall. This opening was enlarged and squared up to the unbroken wooden studs to create an opening large enough for the vehicle to be removed by a tow truck. The bed of the tow truck was extended onto the structure through this opening to add an anchor for a diagonal pull, which was needed to avoid striking the interior walls.

(7) Firefighters cut the metal exterior wall to create access for the tow truck bed.

(8) Technical rescue team firefighters clear a path through the structure.

The interior wall and the second load bearing wall in the middle of the structure were not significantly damaged and did not require additional shoring. Those walls did need to be partially removed to facilitate pulling the truck back through those areas without striking the undamaged part of the walls.

The shoring squad constructed a pneumatic shore comprised of a six- to 10-foot shore with a 4-foot extension. Within minutes, this shore was installed vertically. The shore was installed close to the truck and nailed to the building header and sole plate. The shoring team took measurements of the opening created from the vehicle and began constructing the two-post vertical shore.

The truck was pulled back through the load bearing wall with the use of the tow truck cable and a winch. The wooden two post vertical shore was installed next to the pneumatic shore. After the two-post shore was pressurized with 2×4 wood wedges under each post, the pneumatic shore was removed and returned to the TRT trailer.

Another section of the wall that went from the six-foot, eight-inch doorway height to the 13-foot underside of the roof beams was damaged from the initial impact. This wall is where the spot T shore was installed. The wood shore header and sole plates were toe-nailed into the existing wooden header and sole plate of the building, which is anchored into the concrete floor. Toe-nailing the shore will keep it in place, just in case it was accidentally bumped into during follow up inspection of the structure.

(9) The two-post vertical shore and the T spot shore installed to support the weakened wood girder that was supporting two roofing systems.

Lessons Learned

Calling in the TRT and building inspector added additional insight to creating a safe operational area. It provided more options to remove the vehicle. The additional manpower of the Paducah TRT made execution of tasks more time efficient.

The TRT needed to see the underside of the load-bearing beam. The ceiling and wall needed to be exposed to create access and view the location of the vertical shores. The drop ceiling system at the nine-foot height contained several heavy four-foot-long lights. As the drop ceiling was removed, some lights dropped down and swung sideways on the electrical conduit. These lights had the potential to strike a responder. All lights and cable were cut away to prevent injury or entanglement.

(10) Firefighters remove suspended lighting.

The 13-foot interior height was a challenge to operate at the header. Putting a ladder against the header would add additional weight in a lateral direction. Along with an A frame ladder, firefighters chose to operate on the vehicle roof and hood to elevate their work platform.

While working in the area secured with the pneumatic shore, TRT firefighters began clearing out broken wooded studs by cutting near the header and prying the small remaining part of the boards. This action left the nails in the header protruding downward. The end of the nails prevented an accurate fit of the wood two-post vertical shore. Firefighters corrected this by using a recip saw to cut off the nails.

(11) Technical rescue firefighters clear nails from the girder.

Removing the pickup truck from the structure was necessary. Bringing in additional responders made the operation more efficient. Building stabilization was done is a safe manner by the Paducah Fire Department and their TRT. A safe operational area was created by installing the pneumatic shore near the pickup truck. After the truck was removed, the building was made safer by firefighters installing wood shores. Without shoring, there could have been a collapse while removing the truck. During postincident inspection, there could have been a collapse if the load-bearing wall of it was not supported. Paducah firefighters made a difference by making this a safer incident.

JEREMY RIFFLARD is a captain with Fort Lauderdale (FL) Fire Department and a rescue squad officer for the FEMA Urban Search and Rescue team FL-TF2. He is the lead instructor for the Scaffold Rescue Program at Coral Springs (FL) Regional Institute of Public Safety. For the past 15 years, he has been a rope rescue instructor and subject matter expert with ATEC Incorporated for Military Urban Search and Rescue exercises. He is the ower and program manager for Technical Rescue Training LLC, which was the company delivering training to Paducah, and delivers technical rescue training to military responders through L2 Defense.