Low-Cost Foaming Agent Developed Along With Special Pumping System

A unique foaming agent has been adapted for fire fighting by Mark Cummins of the Texas Forest Service. Combined with the water expansion pump system (WEPS) invented by Cummins, who calls it the most effective fire fighting tool devised to date, the foam is proving to be a most versatile weapon.

Although they have been used mostly for wildfires, the foam and pumping system can be used on ordinary combustible and flammable liquid fires of all types, according to Cummins.

Unlikely foam

He “discovered” the unlikely foaming agent while he was visiting a paper mill and stepped in some slippery, smelly goo. It was a byproduct called tall oil or pine soap, a residue skimmed off when making Kraft paper. It was thought to be useless, but Cummins asked the question: “Does it foam?”

As a matter of fact it did when it was discarded in a stream, he was told. Cummins took it from there, and WEPS is the result.

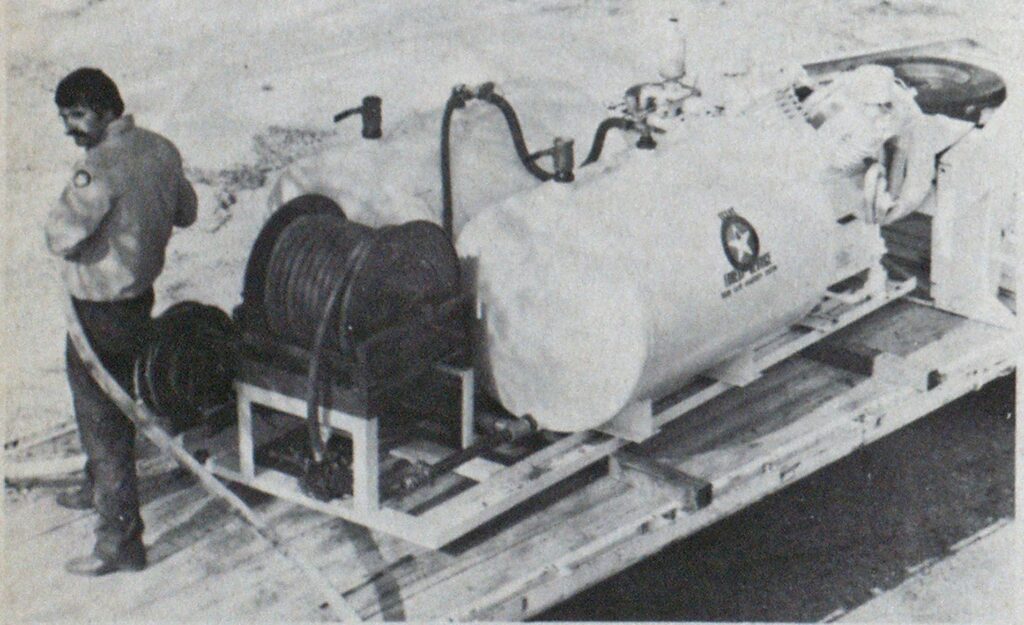

The WEPS is a foam generator composed of a 20-cfm air compressor and a 10-gpm rotary gear pump, both driven by one 10-hp gasoline engine. The foam is delivered from the system by an ordinary 1-inch cotton-jacketed hose and a regular shutoff nozzle. By manipulating the shutoff, the stream’s consistency can be varied from that of liquid to that of shaving cream. When mounted with a 240-gallon water tank, the WEPS measures only 4x6x2 feet. Without the water tank, the WEPS weighs about 300 pounds.

The plumping is simple: tank to pump, pump to hose. There are only three valves: one for the foam solution, one for the air and one for a 1 ½-inch or other outlet.

Adaptable

In spite of (or perhaps because of) its simplicity the WEPS is a surprisingly adaptable machine. Almost any kind of foaming agent will work in the WEPS: regular protein, AFFF, liquid dishwashing soap and the pine soap. The WEPS produces smaller bubbles than is usual, so its foam is a better vapor seal. Regular commercial foams, when used with the WEPS at one-half the manufacturer’s recommended concentration, are noticeably more effective than they are when used at recommended concentrations through typical foam-generating equipment.

The pine soap, however, is the agent most used with the WEPS. The dark brown, viscous substance costs only about $15 for 55 gallons. The pine soap can be used as either a foaming agent or as a wetting agent.

Mixed with water at less than a 1 percent concentration, pine soap produces prodigious amounts of foam. The WEPS’s range of expansion is from 5:1 to 20:1. At 20:1 the expansion of 240 gallons of water/pine soap solution yields 3500 gallons of foam. That comes to 1040 cubic feet, or 2080 feet of foam fire line 24 inches wide by 3 inches deep. The cost of the pine soap for this amount of foam is about 32 cents.

The greatest advantage of the WEPS is that it extends a tank of water. This is invaluable in dry areas where water supplies are scarce. Also, a fire line made with the soap solution can be seen easily, so no water is wasted retreating areas.

Another attribute of the system is its ability to pump foam solution long distances upward with low pressures. In a California test the WEPS produced a satisfactory 40 to 55-foot foam stream with a 2000-foot lay of 1-inch cotton hose when the nozzle was 1000 feet above the pump and the pump pressure was 150 psi.

Other problems remain

Reports from users of the system in the West have been glowing, but Cummins cautions, “Of course, the system is no panacea. It will not offset problems involving delayed attack, poor tactics or unrealistic expectations.” Also, as with any wet line the WEPS produced line is affected by relative humidity, air temperature and wind speed.

Even when Cummins’ warning is taken into account, however, the WEPS seems to be a unique and most useful device compared to other methods and equipment. For example, constructing a fire line is slow and often dangerous. Bulldozers are quick, but they are destructive and cumbersome to transport. Retardant is effective and does not harm the environment, but it is expensive. The WEPS can lay a line at about 50 feet per minute for 40 minutes, can go anywhere a small truck can go (and the long hand lines that are possible also extend reach), and the pine soap is inexpensive and neither toxic nor harmful to the environment.

The pine soap foam is said to be able to cover all types of vegetation (it clings to rough vertical surfaces) and to penetrate dense foliage. An Arizona user suggested that a good use for the WEPS is for the unit to go along with a burning-out crew to pretreat any possible problem areas. The Boise, Idaho, Interagency Fire Center cites four more:

- Establishing a control line for backfiring or burning out,

- Making a direct attack on the flanks and rear of a fire for line building and holding,

- Widening and strengthening existing fire breaks, and

- Pretreating low-lying and vertical fuels.

Another use

Many persons have found that the WEPS is unexcelled for mop-up, almost making pump tanks obsolete. And a California group found an unexpected advantage of the pine soap. They wrote in a Bureau of Land Management report: “The soap concentrate is an excellent degreaser. We have used it to clean both pump engines and vehicle engines with good results.”

Cummins and the Texas Forest Service have applied the WEPS principle to personnel protection as well as to strictly fire fighting. They have replaced the dry chemical personnel protection systems on their tractors with a 10-gallon WEPS unit and a 15-minute breathing air supply. According to Cummins this system has already saved lives that might have been lost otherwise.

“The WEPS foam doesn’t absorb heat as dry chemical will,” he said.

Another problem with dry chemical is that it can get compacted in its container and cannot be discharged when it is needed.

The WEPS is patented, so it cannot be built without permission from the Texas Forest Service. Public agencies can easily obtain permission to build a unit, but the principal injector may not be fabricated for monetary gain. If an agency does not have the desire or the facilities to build a WEPS one can be purchased for about $3900. Write to Mark Cummins, WES Inc., P.O. Box 2510, Lufkin, Texas 75901.