THE DANGERS OF CONFINED-SPACE EMERGENCY OPERATIONS

RESCUE

WILL YOU BE A RESCUER OR A FATALITY?

IT HAPPENS to every fire department at one time or another. A call comes in reporting a person trapped or “down” in a manhole or a storage tank, or perhaps a child is trapped in a sewer pipe or well.

While the rescue of those who are helpless is one of the most noble undertakings of our profession, serious consideration must be given to the proper way in which to accomplish the rescue. No amount of preplanning can cover every conceivable type of incident, but certain hard and fast policies can and must be implemented to cover specific classes of rescue operations.

Perhaps nowhere is the need for effective preplanning more evident than in dealing with rescue operations within confined spaces. The National Institute for Occupational Safety and Health (NIOSH) has, for the past six years, been conducting investigations of confinedspace fatalities as a part of its Fatal Accident Circumstances and Epidemiology (FACE) Project. Noted in these investigations is the regularity with which responding rescuers rush in to the scene without regard for their own safety. Often, this recklessness brings disastrous results as rescuers themselves become victims.

As of October 1, 1988, NIOSH has investigated 48 confined-space incidents resulting in 70 fatalities. Of these 70 fatalities, 19 (27%) of the victims were would-be rescuers. Firefighters, in spite of training to the contrary, show a disconcerting tendency to make wellintentioned yet ill-advised rescue attempts in the manner of untrained civilians. In the 48 confined-space incidents noted above, one firefighter lost his life and 29 firefighters were injured.

Let’s review four NIOSH confinedspace fatality investigations to illustrate common errors made during these types of rescue operations.

CASE #1

On October 10, 1986, an inspector entered an underground vault 12 feet long, 6 feet wide, and 8 feet deep to inspect a backflow prevention device on a water line.

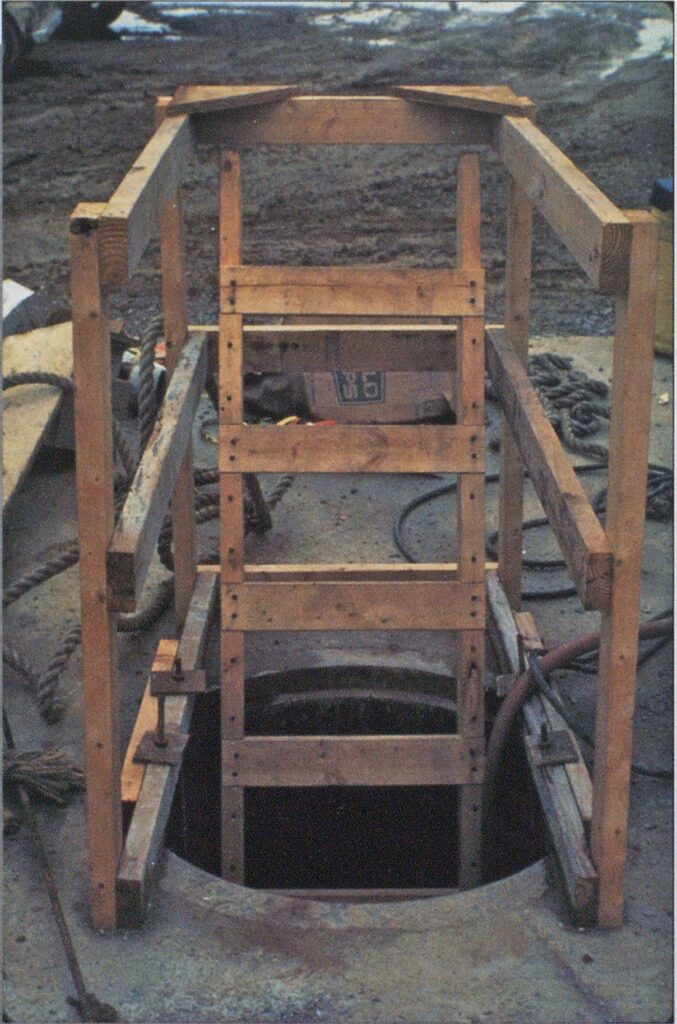

Access to the vault was made via a 30inch-diameter manhole at ground level. The inspector removed the manhole cover and lowered a ladder into the vault. At the time the inspector entered the vault, the floor was covered with 14 inches of water.

Later, a passerby observed the open manhole, looked into the vault, and saw a body in the water at the bottom. The passerby notified nearby office staff, who called the emergency squad. In the meantime, a shipping supervisor and a maintenance man entered the vault in a rescue attempt. Neither of these men was wearing any type of respiratory protection, and within two to three minutes, both men passed out. Two police officers entered the vault, also without respiratory protection; they became weak and disoriented, and had to be helped from the vault. When the rescue squad arrived, two paramedics entered the vault — without respiratory protection. These men also had to be helped from the vault. A fire department engine company reached the scene, and, using self-contained breathing apparatus, removed the three men from the vault.

The inspector and the shipping supervisor were pronounced dead on arrival at the local hospital. The maintenance man was hospitalized in serious condition, but he survived. The two police officers and the two paramedics were treated and released. Tests of the atmosphere in the vault revealed an oxygen level of 7%, with a CO2 level of greater then 3%. It appears that bacterial growth had depleted the oxygen level within the vault.

CASE #2

On June 6, 1987, a maintenance worker for a municipal wastewater treatment facility entered the facility’s “wet well” (a 27by 18by 26-foot-deep pit) to clean a “bar screen” that kept large debris from entering the sewage treatment plant.

On the day of the incident, the victim had entered the well four times in three hours to clean this screen. After the fourth time, a co-worker noticed the victim missing. He looked into the well and saw the victim’s left leg protruding from the surface of the sewage. The coworker ran to the office and told personnel to call the fire department. When he returned, he and another maintenance worker climbed into the well to attempt to recover the victim’s body. Both men became faint and nauseated and exited via the access ladder.

When the fire department arrived on the scene, two firefighters wearing SCBAs entered the well and retrieved the victim’s body. A third firefighter, unequipped with respiratory protection of any sort, entered the well to photograph the scene. He experienced lighthcadedness and eye irritation.

CASE #3

On March 22, 1988, a laborer and a supervisor were working inside a 700,000-gallon, elevated municipal water tank, performing routine maintenance on a cathodic protection system.

Access to the tank was through a 2by 2-foot manway at the top of the tank, and a rope ladder was used to descend to the tank floor. The tank had been drained, but a small amount of water remained in the bottom.

After working for 4 1/2 hours, the laborer climbed out of the tank and descended to a catw alk located at the 125-foot level. When the supervisor failed to follow him, the laborer returned to the manway opening and called to the supervisor, who answered that his arms were going numb and that he needed help.

The laborer descended the rope ladder but was unable to rescue the supervisor, who was now unresponsive and unconsciously clinging to the rungs. Loosening his grip, he fell 50 feet from the rope ladder to the floor of the tank. The laborer climbed to the top of the tank and called to nearby individuals that a man was down and needed help.

The local fire department responded, ascended to the catwalk, and opened an access port on the side of the tank to rescue the victim. Three firelighters entered the tank without respiratory protection, removed the victim from the tank, and transported him to a local hospital, where he was pronounced dead. It appears that a medical problem may have caused the victim to fail, although this has not been confirmed.

While firefighters in this case hoisted a Stokes litter and related rescue equipment up the tower, no provision was made for either the use of SCBAs or testing the atmosphere within the tank prior to entry.

CASE #4

On March 11, 1988, a lead cable splicer for a large utility company entered a 10-foot-wide by 12-foot-deep by 80-foot-long underground transformer vault to verify that circuit protectors on the transformers were closed.

F.ntry to the transformer vault was through a 27-inch-diameter manhole, with a fixed steel ladder providing access to the floor. At the time of the incident, two 220-volt sump pumps were not operational and 33 inches of water had accumulated in the vault. Therefore, the employee was wearing rubber hip waders.

The employee touched a section of a vertical sump pipe, which had been energized by an electrical fault in one of the sump pumps, at the same time that he grasped the steel ladder, and was electrocuted.

A co-worker noticed the victim lying face down in the water, entered the vault to rescue him, and received an electrical shock. Numerous rescue attempts were made by other individuals, including police officers and paramedics. All of these individuals received electrical shocks. Shortly after the utility company had disconnected the power to the vault, a fire department rescue squad arrived and accomplished the rescue. The victim was rushed to a local hospital, where he was pronounced dead on arrival.

CONFINED-SPACE EMERGENCY OPERATIONS

In the first three cases, firefighters responded to a scene where a man was “down” within a confined space for unknown reasons, yet no attempts were made to verify the condition of the atmosphere prior to entry. In only one case (#1) did all the firefighters use self-contained breathing apparatus when entering these confined spaces, and even in this case both police officers and paramedics had entered these areas without respiratory protection.

In Case #2, a firefighter, in spite of the facts that others were known to be suffering respiratory difficulty within the confined space and that his fellow firefighters had used SCBAs when entering the area, still entered the confined space without respiratory protection, for the purpose of taking photographs of the accident site.

Although the atmosphere in Case #3 proved to be no threat to rescuers, all firefighters entered the confined space without checking the quality of the atmosphere within the tank and none made provisions for the use of SCBAs in the area. The successful removal was a matter of luck. The circumstances on arrival should have forecast, by size-up, that a probable dangerous atmosphere existed and respiratory protection was mandatory.

In Case #4, firefighters arrived on the scene of an electrically related confined-space fatality moments after the power was disconnected. The rescue in this case was accomplished successfully; however, here again no attempt was made to verify atmospheric conditions prior to entry.

To handle such potential disasters within your department, information concerning confined-space and rescue operations needs to be addressed. Standard operating procedures (SOPs) must be adopted and communicated through effective training programs. Some of the points that will impact your program are:

1. Identification of confined spaces. What constitutes a known confined space within your community? Some common types of confined spaces are storage tanks, pipelines, manholes, silos, and utility vaults. Less common but equally dangerous types of confined spaces are vats, pits, and the like. The fact that some of these spaces may have totally open tops in no way lessens the hazards posed by chemicals or residual atmospheres within. In fact, these situations may increase the hazard by giving personnel a false sense of security that the area does not pose the threats commonly associated with confined spaces.

Identification of confined spaces should be included as a part of your ongoing fire inspection program. Confined spaces thus identified can be “posted” with appropriate warning signs for the protection of both your staff and others. A log of confined spaces in your jurisdiction can be prepared, listing the hazards known to exist within them.

Remember, however, that conditions within confined spaces can change dramatically within a relatively short period of time. Therefore, atmospheric precautions such as those described below must be taken whenever entry into a confined space is made. NEVER permit your inspectors or other department personnel to enter a confined space without following established confined space entry procedures!

2. Hazardous atmospheres within confined spaces. Generally, hazardous atmospheres within confined spaces may be broken down into three types:

a. Oxygen-deficient atmospheres.

An oxygen-deficient atmosphere is considered to be any atmosphere with less than 19.5% oxygen. Oxygen-deficient atmospheres should never be entered without the use of SCBAs. These atmospheres may be created by work being done within the confined space, such as welding or cutting; by natural action, such as chemical reaction (rusting) or bacterial action (fermentation); or by inadequate ventilation.

b. Flammable atmospheres. Flammable atmospheres may be caused by the presence of gas, vapor, or dust within a confined space. In some cases, items not normally considered “flammable” (such as grain dust) may be potentially powerful explosives within a confined space. Furthermore, some confined spaces contain oxygen-enriched atmosphere. In such situations the flammability of the contents may be enhanced significantly, greatly increasing die danger of fire or explosion.

CONFINED-SPACE EMERGENCY OPERATIONS

c. Toxic atmospheres. Most substances found within a confined space should be considered hazardous, and many may be toxic within the environment of a confined space. The mere fact that a confined space is “empty” or has been “cleaned” does not necessarily mean that the atmosphere within the tank is nontoxic.

Because these three types of atmospheric hazards are quite common to confined spaces, fire departments should adopt and enforce the following policy regarding operations in those areas: Either (a) test the atmosphere prior to entry, or (b) treat all confined spaces as having oxygen-deficient/flammable/toxic atmospheres, thus requiring the implementation of specific entry procedures.

Since time and/or equipment may not be available at the scene to allow atmospheric testing, the latter is usually the safest and most practical procedure. This means that all personnel involved in space entry should be wearing and using SCBAs. All equipment used in rescue operations must be of explosionproof design. Equipment capable of producing a spark, including radios that are not intrinsically safe, must be banned from the rescue operation. Firefighters should wear full personal protective equipment, including lifelines, when working in confined spaces. In addition, where corrosive or unknown chemical compounds are present within the confined space, provision should be made for decontamination of the rescuers after operations.

3. Other confined-space hazards. In addition to the atmospheric hazards noted above, other types of hazards may exist within confined spaces. These include:

a. Electrical/mechanical hazards. Many confined spaces will contain energized electrical equipment and/or moving mechanical parts. These hazards must be identified, deenergized, and secured prior to entry. Department preplanning should include procedures for deenergizing/seen ring (lockout-tagout) any equipment encountered during confined-space operations. These procedures should include emergency response of competent service personnel.

b. Engulfment hazards. Loose, granular material such as grain, coal, and sand can crust or “bridge” over when stored in bins, hoppers, and silos. Should a bridge give way under a firefighter’s weight, he, as well as the victim he is attempting to rescue, can become engulfed in the material. For this reason, the use of lifelines should be required by department personnel during rescue operations in confined spaces.

A department that addresses these concerns in its training programs and develops a plan of action for dealing with confined-space rescue operations greatly enhances its ability to perform a successful rescue, while at the sametime ensuring that the risk to the rescuing firefighters is minimized.

The following checklist may be useful in preparing a confined-space rescue program for your department:

- Locate known confined spaces in your primary service area. Preplan rescue operations for these known sites. Post warning signs at known confined spaces whenever possible.

- Ensure that responding units are familiar with the types of hazards likely to be encountered in confined-space rescue operations (atmospheric harards, electrical hazards, engulfment hazards, etc).

- Ensure that units that will be assigned to a rescue operation have all necessary tools and equipment on board.

As with other types of fire department operations, periodic refresher training should be given to all personnel in the “hands-on” use of the equipment they will utilize for confined-space rescue operations.

- Never enter a confined space without SCBA unless you have tested and verified the quality of the atmosphere within the space.

- Always wear full protective equipment. including harnesses/belts and lifelines attached.

- Always employ a “buddy” system, with designated members of the crew remaining outside the confined space to assist those performing the rescue.

- Periodically conduct confinedspace rescue simulations to develop and maintain the skills needed to conduct effective confined-space rescues.

Requests for technical information and NIOSH publications on confined spaces and other safety hazards may be obtained by writing:

National Institute for Occupational Safety & Health Technical Information Branch Robert A. Taft Laboratory 4676 Columbia Parkway Cincinnati, Ohio 45226

or by calling NIOSH at 1-80035NIOSH.

SELECTED BIBLIOGRAPHY

NIOSH Criteria for a Recommended Standard “Working in Confined Spaces,” DHHS Pub. No. 80-106.

NIOSH “Guidelines for Controlling Hazardous Energy During Maintenance and Servicing,” DHHS Pub. No. 83-125.

NIOSH “A Guide to Safety in Confined Spaces,” DHHS Pub. No. 87-113.

NIOSH “Posting of Confined SpacesWarning,” Richard W. Braddee and Ted A. Pettit. Professional Safety, February, 1987.