Special Teams in Memphis Handle HazMat Incidents

FEATURES

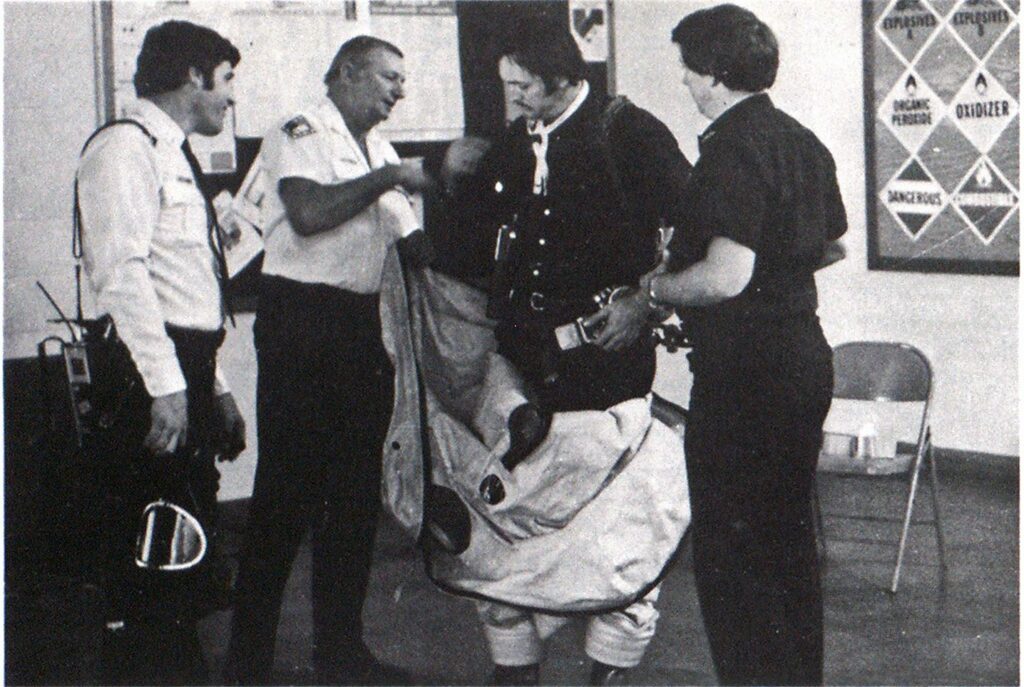

Photo by Training Division, Memphis Fire Services

The Memphis, Tenn., Fire Department had good reason to be concerned about hazardous materials incidents.

Known as “the agricultural chemical center of the mid-south,” Memphis is a transportation hub. Six major rail terminals within the city make Memphis the third largest rail center in the nation; only Chicago and Denver are larger. The Illinois Central Gulf complex is the second largest railyard in the United States. There are 70 major truck terminals within the metropolitan area, and through the Port of Memphis moves the third highest level of barge traffic in the country in terms of tonnage. Federal Express Corp., transporter of nearly 90 percent of all small-package hazardous materials shipments, has its headquarters in Memphis.

Response teams organized

In early 1978, Robert W. Walker, director of Memphis fire services, authorized two hazardous materials REACT teams that were organized and trained in cooperation with Memphis and Shelby County Civil Defense authorities.

Captain J. W. Covington has been involved with the REACT effort since the beginning.

“Lieutenant Tom Sharp and I are actually assigned to the Hazardous Materials Section of the Office of the Fire Marshal, one of four divisions that form the Memphis Division of Fire Services,” notes Covington. “For a number of years we have inspected any location in the city where hazardous materials are present We began to give serious thought to developing a hazardous materials response team staffed by specially trained members, and scheduled a meeting for a Monday in late February of 1978 to initiate efforts to form a couple of teams and acquire specialized equipment. On the preceding Friday, the tragic LPG tank car explosion occurred just 120 miles up the rail line at Waverly, Tenn. The 16 dead at Waverly spurred on our organizational efforts. We used our Monday meeting to deal with the federal people on a grant for initial equipment.”

Fire fighters within the 1400-man Memphis Fire Department were sought as volunteers for the new teams.

“We had approximately 300 fire fighters apply for 55 positions,” remembers Covington. “There was never a problem of attracting manpower; the difficult part was choosing exactly the personnel we wanted from among the hundreds who applied.”

Priority in selection was given to fire fighters who had training in chemistry, physics, health sciences, industrial safety and fire science technology—or actual experience in operating earthmoving equipment.

Industry assistance

“The program started in April of 1978 with 55 men selected to attend 91 hours of initial training,” says Covington. “We utilized people from local industry to provide much of the training. Various companies were asked to present programs dealing with the proper handling and control of their particular products. Whenever possible, they brought along equipment for ‘hands-on’ training. Organizations providing training assistance included Ryder Truck Lines, Wooten Truck Lines, the U. S. Coast Guard, Du Pont, the Frisco Railroad, Federal Express, Texgas, Riverside Chemical Co., Delta Refinery, the Burlington Northern Railroad, Memphis Police Department, and a number of others. Of all the people from industry in the area who were asked to help with our training, not a one refused.”

Memphis REACT Team Equipment

2 chemical suits

2 SCBA with extra bottles

1 gas detector

2 proximity suits

1 pair field glasses

1 set sparkproof tools

6 pairs rubber gloves

1 first-aid kit

1 20:BC fire extinguisher

1 hand spotlight

2 long-handled spades

1 civil defense radio

6 disposable rainsuits with boots

1 35mm camera

wooden plugs tapered 1 to 6 inches

1 roll Parafilm

1 Craeger chemical detector with tubes

1 pack pH paper

1 resuscitator

2 portable radio chargers

1 Nomex jump suit

2 rolls duct tape

1 plumber’s inflatable pipe plug grounding cables hose clamps

1 fire department portable radio with attached speaker mike

1 carrying case for hazardous materials library

1 case for water main maps of Interstate system

radiological monitoring equipment (dosimeter, Geiger counter, ion chamber)

Additional Snorkel Equipment:

2 flexible hatch funnels

4 dome cover clamps

1 air chisel

2 life lines

4 air bags

A, B and C chlorine kits

- Guidelines for HazMat Operations

These guidelines for operations at hazardous materials transportation were distributed to all officers shortly after the REACT squads were formed in 1978. To minimize exposure to company personnel until the materials and general incident have been evaluated, it is Intended that the first-arriving company establish the primary command post, secure the area, attempt to identify the materials involved and, unless life hazard or fire potential exists which would require immediate action on the part of the company, stand by for arrival of the REACT chief and/or REACT squad.

FIRE ALARM OFFICE

Who is to be dispatched?

- Pumper company.

- District chief.

- REACT fire squad.

Note: Notify deputy chief. He is dispatched at the discretion of the fire alarm office.

Information given to responding units:

- Location (the exact number related to street corner, intersections, cross streets, or other physical land markers, such as large buildings, signs, etc.

- Disposition (if known):

- Type of hazardous material involved.

- Visible activity showing (smoke, fire, etc.).

- Type of vehicle involved.

- Type of placarding (flammable, corrosive, etc.).

- Traffic control information (streets blocked, etc.).

- Weather report.

- Any other helpful information (nearby fuel farm, school, hospital, etc.).

FIRST ARRIVING UNITS

Position apparatus upwind, at a safe distance (300 feet) and headed in opposite direction from incident.

Information to fire alarm office:

- Location.

- Disposition.

Note: When arriving on the scene, if information given initially is correct, then no amplification or clarification need be made. Simply report on the scene and give a short disposition. However, if location or disposition is different, go ahead and give updated information.

APPROACHING THE INCIDENT

Determine if the incident can be safely approached through observation and any other available Information.

- If unsafe to approach:

- Notify the fire alarm office of any unsafe condition (leakage of class A poisonous gas, trailer of explosives on fire, BLEVE, etc.).

- Move company and apparatus to a safer area.

- Designate staging area for nextarriving apparatus.

- Continually update information to fire alarm office.

- First-arriving chief officer will respond to location.

- The possibility of a large-scale evacuation should be considered at this time; however, immediate area evacuation should be started at once.

- If an approach can be made:

- Do it with two men.

- Wear full protective clothing.

- Wear SCBA.

- Use natural barriers (hills, gullies, etc.).

- Secure shipping papers, wheel reports, or lay lines for heavy stream appliances.

(For immediate self-protection, any available options may be used such as 1 1/2-inch AFFF line, CO2, dry chemical, booster line).

SET UP COMMAND POST

Primary command post (key personnel):

- Fire department.

- Director of fire services.

- Deputy director.

- Staff officers.

- Mayor.

- Law enforcement agencies.

- Director of civil defense.

- Shipper representatives.

- Manufacturer representatives. Secondary command post:

- Support personnel:

- Public works.

- Light, gas, and water.

- U.S. Coast Guard.

- News media.

- Hospital representatives.

- Support equipment (fire department):

- A-6.

- Air truck.

- Hose tender.

- Dump truck.

- Front-end loader.

- Helicopter.

- Off-loading fuel tankers.

- Wreckers.

The five-man REACT squads provide 24-hour coverage to the city. One is located on the western edge of town in a heavily industrialized area along the river; the second is in the central area of the city. The squads are dual-purpose units, and their primary purpose is to respond on regular fire suppression alarms. If both REACT teams are assigned to fire calls when a hazardous materials incident occurs, the team nearest the incident will be reassigned.

The squads have now received over 200 hours of specialized training. In each REACT team station an in-service training area has been established to allow training, both new and refresher, every day a squad works—without placing the squad out of service.

Covington and Sharp work a 40-hour week but are on call 24 hours a day, seven days a week, through a pager network. REACT squad members work a 24-hour shift. Sharp and Covington each have four-wheel-drive Suburbans, and the REACT teams are equipped with elevating platforms. All four vehicles carry the same equipment with minor differences.

“The REACT squads went with the Snorkel apparatus because they have plenty of compartment space into which we can cram the rather extensive response equipment we carry,” explains Sharp. “Storage space, purely and simply, was the major reason we went with the Snorkel units.”

The Memphis Fire Department averages one hazardous materials call every three days, not counting extremely minor incidents that might involve a 5-gallon can of gasoline, for example. A normal dispatch on a hazardous materials incident is one engine company, one truck company, one REACT squad, a battalion chief, and either Covington or Sharp. Covington and/or Sharp respond to every hazardous materials incident in the city, where they act as advisers to the battalion chief, the on-scene commander.

“We report to the battalion chief as soon as we arrive on site,” adds Sharp, “get our heads together, determine the best approach to take, then make our decisions. The battalion chief’s decision is final; he is the man in charge.”

Portable library

“There is a very complete hazardous materials reference library in each of the two Suburbans assigned to Sharp and myself,” adds Covington. “Obtaining water for a major incident on the Interstate system sometimes presents major operational problems, so we carry maps showing the location of all fire hydrants that might be reached quickly from the Interstate system. These maps are kept in the command post vehicle, and any additional fire fighting apparatus responding to the incident can be notified by radio of the location of the nearest available hydrant. Another aid in locating water on the Interstate system is reflectorized fire hydrant identification signs that designate both the street and number of the nearest hydrant location and the distance from the sign to the hydrant.”

While REACT squad personnel have all the normal duties of regular fire companies in addition to their hazardous materials response duties, Sharp and Covington’s only assignment is hazardous materials. All they do every day is inspect facilities that handle hazardous materials. . . or actually respond to incidents.

“We are currently surveying 200-plus locations in the city that we know handle large amounts of hazardous materials,” says Covington. “On survey forms we ask what they handle, in what amounts, and similar information. On another sheet we ask them to make a simple drawing of their facility. We tried to develop a form that would be simple for the industrial people to fill out yet give us the basic information we need. The form gives us a starting point. We then visit each facility and update the form against the actual location, adding anything of interest that the industrial person may have failed to note. We use the final version of the survey forms in a preincident manual to be placed on the REACT teams’ apparatus and used during in-house training to familiarize the fire fighters with the ‘what and where’ of these facilities. The form also covers water supplies; master shutoffs for electricity, gas and ventilation; piping and valves; and similar concerns.”

Lines of communication

Memphis fire personnel stress the benefits of establishing strong and continuing lines of communication and working relationships with carriers, manufacturers, and others concerned with the transportation of hazardous materials. City representatives meet monthly with the superintendents or assistant superintendents and other officials of the seven railroads serving Memphis. City officials also meet monthly, under the auspices of the Tennessee Safety Supervisors’ Association, with representatives of 87 large truck lines serving the area. An industrial association with fire service sponsorship, it encourages the development of in-house plant protection programs; the fire marshal’s office provides training for plant fire brigades.

Regional response teams attached to the major chemical companies in the area interact closely with REACT team personnel, often provide training aids, and provide on-site technical assistance and specialized equipment when requested. The fire marshal’s office maintains liaison with a toxicologist at a local hospital who will respond as a volunteer technical adviser.

“Good teamwork is fostered by such regular meetings, during which the people who will be involved during an emergency get acquainted and learn how to communicate with each other,” concludes Covington. “We have learned to rely on industry for guidance and direct assistance, particularly for tips on cleanup techniques and the handling of certain chemicals. We feel strongly that response people need to work closely with their local industrial people who handle their own products every day. It is crucial to learn whom you can talk to and who will know what you are talking about. For example, we have one of the largest Du Pont plants in the nation located here, and we work very closely with Du Pont personnel. Knowledgeable industrial people are the ones you need for training on particular products. We rely on such people. We have never yet had a turn-down from any industrial outfit that we asked for help.”