Leaking Underground Storage Tanks

FEATURES

HAZARDOUS MATERIALS

Some Solutions to and Legislation Addressing L.U.S.T

An estimated 100,000 of the more than 2-million underground gasoline storage tanks in the United States may be leaking, according to petroleum experts. And within the next five years, up to 350,000 of these tanks are expected to leak.

Of course, gasoline is only one of a variety of liquids stored in underground tanks. Toxic and process chemicals, domestic fuels, flammable and combustible liquids, and diluted wastes are some other hazards seeping out of underground containers. These leaks result from:

- External and internal corrosion (groundwater, soil, fuels, chemicals).

- Punctures or cracks in tanks, pipes, fittings, and dispensers.

- Improper installation of pipes and fitting connections. (It has been estimated that 60% of underground leaks occur in the piping.)

- Improper bedding, backfilling, and anchoring of tanks.

- Natural and unnatural ground movement (earthquakes, floods, adjacent construction).

The leaking underground storage tank (L.U.S.T.) is a serious threat to human health and environment. In addition to posing a contamination hazard to groundwater reservoirs that provide drinking water for more than half the United States, the contents of L.U.S.T.s are also surfacing in basements, sewers, utility conduits, and wells, releasing toxic vapors into the atmosphere.

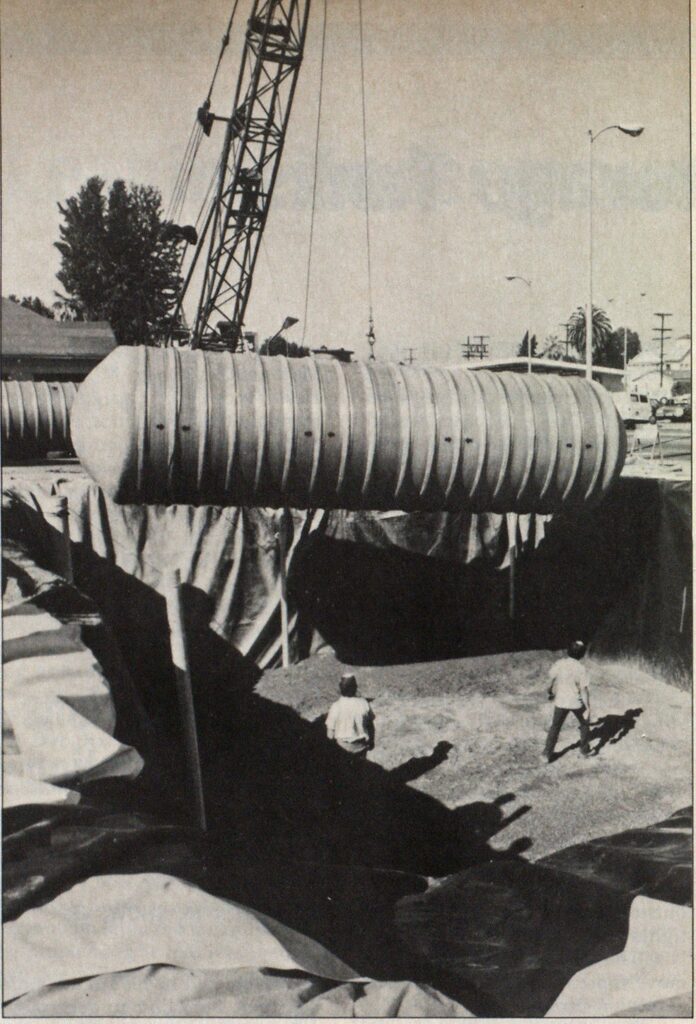

Photo courtesy of Hanes & Associates

Whether or not such a situation presents an immediate hazard depends on how much liquid or vapor is involved, where it is found, how it is confined, possible sources of ignition, etc. However, because combustible liquids (those having a flashpoint at or above 100°F) and flammable liquids (those having a flashpoint below 100°F and easily ignited) unconfined in the ground can move from place to place, any indication that such liquids have escaped into the ground must be considered as a potential, if not immediate, hazard, according to the National Fire Protection Association (NFPA) 329, Recommended Practice for Handling Underground Leakage of Flammable and Combustible Liquids.

There are basically two methods of detecting leaks, inventory control and tank tightness (precision testing). Before beginning actual equipment testing, however, ensure that spills during transfer or deliberate disposal are not the leakage source. Keep in mind that liquids may travel slowly underground or not at all until the water table rises. So there can be a considerable time lapse between the occurrence of a leak or spill and a report of finding vapor or liquid.

Although control monitoring can usually detect catastrophic leaks, this procedure is susceptible to certain factors, such as:

- Dispenser meter errors.

- Mismeasurements resulting from disparity between underground and ambient temperatures. A drop of 1°F will shrink 1,000 gallons of gasoline by 0.6 gallons.

- Discrepancies between reported and actual delivered quantities.

With regard to tank tightness testing, even recognized precision tests for testing underground tanks have maximum detection limitations of 0.05 gallons/hour (NFPA 329). This translates into a 1.2 gallon/day/tank of fuel or chemical loss which can be undetectable. (One gallon of contamination can pollute as much as 1-million gallons of groundwater.)

There are several solutions to help alleviate potential leaks in underground storage tanks. One is the use of fiberglass storage tanks that are essentially corrosion proof. Double-walled tank installations are another protection against leaks. A third method involves a process called cathodic protection, in which tank corrosion is slowed by electrically bonding magnesium to the outside of the underground steel tank so that the magnesium corrodes instead of the tank.

A fourth method to deal with L.U.S.T. is the use of a flexible elastomeric liner. This liner can be installed into the storage tank hole and along the trench under all tanks and piping. In this way, any leakage is confined within the space of the liner system. The bottom of the tank hole itself is graded lower at one end, forming a well with a leakage indicator where spilled fluids would accumulate and be easily detected.

In order for any liner system to be effective, it must meet certain criteria:

- Compatibility. The liner must be chemically resistant to the products contained within the tank.

- Expected service conditions. Is the tank site subjected to shifting ground conditions so that flexibility

- of the liner is important? What are the soil conditions at the tank site? What is the fungus and mold resistance of the liner? Is the tank in a high or low groundwater area?

- Construction. Is the liner flexible or will it crack under expected service conditions? Does it contain a plasticizer that could be extracted, causing the liner to become brittle? How will it hold up under various temperatures? How is the liner fabricated and how reliable are the seams? To what de-

- gree is the liner puncture resistant?

- Long-term reliability. Is the life expectancy of the liner at least as long as that of the tanks?

- Permeability. Perhaps the most important property needed in a secondary containment liner is low permeability to the fluid to be contained. When tanks and associated piping leak, the secondary containment liner becomes a primary containment system.

While chemical companies have improved their environmental safeguards under increasingly strict regulations over the past 15 years, the regulation of underground storage tanks came under the Environmental Protection Agency (EPA) only last November. The Hazardous and Solid Wastes Amendments of 1984 to the Resource Conservation and Recovery Act (RCRA), public law 98-616, were passed allowing the EPA to take a more direct role in the regulation of L.U.S.T. On November 8, 1984, the amendments took effect and for the first time the RCRA law, which provides “cradle to grave” management of hazardous wastes, applies to storage of products as well as wastes.

The new statutes regulate all underground storage tanks containing petroleum products and all substances defined as hazardous under the Superfund law. The program authorizes:

- Registration of all underground storage tanks with state or local agencies to determine the age, size, type, location, and uses of tanks throughout the country.

- Registration is required even for tanks taken out of use but not removed from the ground.

- Federal technical standards for new and existing tanks.

- Federal inspection and enforcement.

- Reports to Congress.

- State L.U.S.T. programs and grants. The new L.U.S.T. program is to be conducted by the states. Several states have already assessed the potential number of and damage caused by leaking underground tanks. New York estimates that 19% of its 83,000 active underground gasoline tanks are leaking; Maine estimates that 25% of its 1,600 retail gasoline outlets have underground tanks leaking a total of 11million gallons/year; and a Michigan survey found that at least 21% of 268 known groundwater contamination incidents involved petroleum product leakage.

State laws and local laws applying to underground storage tanks have passed in California, Maryland, Michigan, and Austin, TX. Connecticut, Delaware, Florida, New Jersey, and New York are considering regulations, and many other states are working on new laws and regulations. Currently, California; Rhode Island; Austin, TX; and Puerto Rico require secondary containment.

Basically, the law requires that after May 7, no underground storage tank may be installed unless:

- It will prevent releases due to corrosion or structural failure for the life of the tank;

- It is cathodically protected against corrosion, constructed of non-corrosive material or its equivalent, or designed to prevent the release or threatened release of the stored substance (e.g., tank and secondary containment liner); and

- The tank (or liner) is compatible with stored substances.

The statute requires EPA to develop new tank performance standards and standards concerning release, detection, prevention, and corrective action applicable to all tanks during the next 45 months.

The RCRA is due to expire this fall, and it is the focus of reauthorization hearings in both Houses of Congress.