Carbonized Wood Ignition Determined in 4-Alarm Fire

features

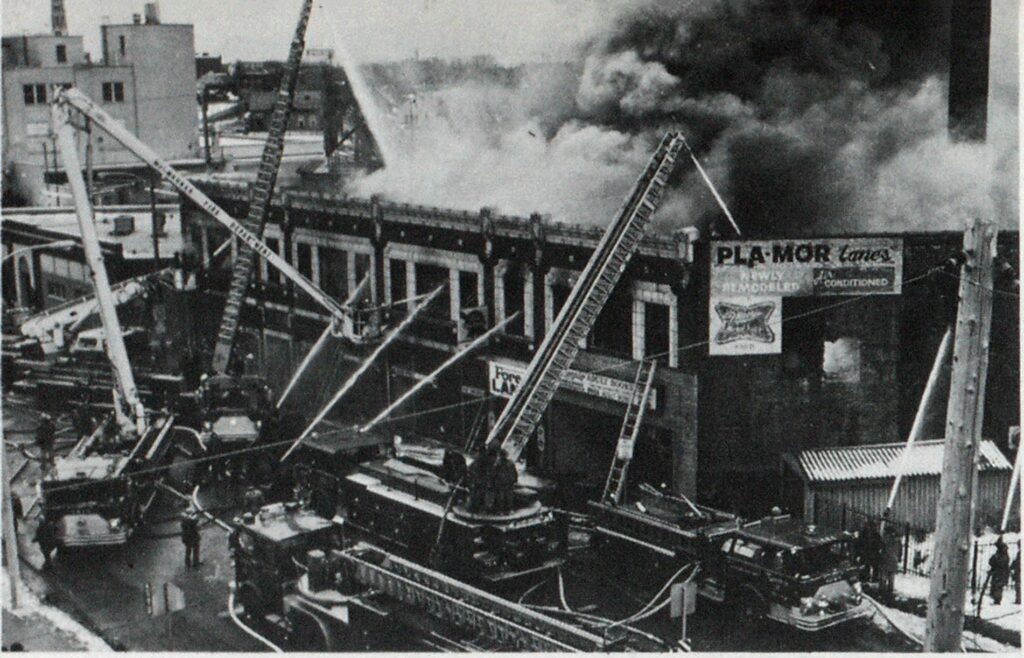

—Milwaukee Sentinel photo.

“Pyrophoric” literally means “air burning.” It refers to the tendency of certain materials to take fire spontaneously upon exposure to air without any other specific ignition source.

This isn’t quite the same way that spontaneous combustion takes place in hay, rags, or metal turnings, with which most fire fighters are familiar. In these cases, chemical reactions with little air present can build up surprisingly high temperature within a closely packed mass of material until the normal ignition point is reached and active combustion begins.

A pyrophoric material, on the other hand, need never reach a high ignition temperature. It is in such a state of potential chemical reactivity that its mere exposure to air of normal temperature will begin the burning process. One such material is metallic sodium. Another is the silane gas used in the manufacture of some electronic components.

Wood becomes pyrophoric

Those are “exotic” materials the average person never sees. But under the right circumstances, ordinary wood (typical carbon content 50 percent by weight) can become pyrophoric. Heat is needed to bring about the transformation, but if continued long enough, the process can occur at fairly low temperature. Moisture and other volatiles are gradually driven off. The various cellulosic compounds within the wood structure are converted to carbon— which without further temperature increase will eventually reach a pyrophoric state and begin to burn. The fire triangle is not incomplete. It’s just that the amount of heat (temperature) needed in one leg of the triangle has become unusually small.

Here’s what the NFPA “Fire Protection Handbook” says on the matter: “Wood in contact with steam pipes or similar constant temperature sources over a long period of time may undergo a chemical change resulting in the formation of charcoal which is capable of heating spontaneously. It has been suggested that 212° F is the highest temperature to which wood can be continually exposed without risk of ignition.” Furthermore, “Under certain conditions, charcoal reacts with air at a sufficient rate to cause the charcoal to heat spontaneously and ignite.”

There seems to have been little experimental work to verify just how high a temperature may be safe for extremely long periods of wood exposure. In one test, a 2-foot-thick stack of wood fiberboards ignited in 96 hours at 228° F. (Normal wood ignition temperature ranges from 380 to 500 degrees.) Other data shows that in 30 percent humidity, temperature of less than 150 degrees reduces wood’s normal moisture content to less than 5 percent.

Increasing problem

The formation of pyrophoric carbon through slow oxidation of wood has become of growing importance to the fire service recently because of the increasing number of unsafe, do-it-yourself space heating installations, such as wood stoves. Carbonization of adjacent structural parts takes place fairly quickly at high temperatures, however. When you see a stovepipe or chimney flue added to a residence, the potential danger is obvious.

Where there is no such high temperature heat source, however, the problem may go unsuspected indefinitely. That’s the situation which confronted the Milwaukee Fire Department last Jan. 15. At 7:51 a.m., a telephone caller reported fire in the basement of a 100 X 200-foot, two-story, brick and timber commercial building on the city’s south side. Extensive remodelling over many years had resulted in a maze of false ceilings and partitions in that basement. A bowling alley with service bar had been constructed in one end by excavating what had been the building’s rear yard and then capping the excavation with a concrete deck.

For over an hour, fire fighters from three engine and two ladder companies, aided by several more units specialcalled to the scene, tore into ceilings and walls in a vain search for the seat of the smoky blaze. Despite their efforts to cut off vertical extension through nonfirestopped walls and service openings to a janitor’s closet in the upstairs apartments, the fire built up heat and pressure throughout an undivided cockloft. That eventually blew down upstairs ceilings to involve the entire second floor. The fire then vented itself through the roof.

Master streams used

Three additional alarms were sounded. Master streams on all sides of the building brought the flames under control shortly before noon. The fire was declared out after more than 11 hours work by 115 men from 13 engine and six ladder companies, using more than 40 hose lines up through 5-inch. Reduced to a roofless shell upstairs and flooded downstairs, the building was considered a $300,000 total loss.

Here’s what the fire department’s investigation team, called in before 9 a.m., then discovered: The building had been erected in 1921-1922. Originally, it had used a steam heating system supplied from a central boiler room. Properly wrapped piping was used throughout. Some years ago, this system was converted to hot water heat. Numerous renovations in the basement, where a disco had been put in as well as the bowling alley, generated a need for more heat in various rooms.

So three of the old steam radiators, now tapped into the hot water system, were clamped directly against the underside of 2 X 12 floor joists above the basement ceiling. In some areas, there were actually three such ceilings separated by furring strips—a lower dry-wall ceiling, one above it of acoustical tile, then a third of metal lath over which no plaster had been applied. Opening all these caused fire fighters a great deal of difficulty.

Radiators enclosed

To channel some warmed air from these radiators horizontally into other rooms, makeshift ducting had been built around each radiator, concealing it from view, and leading off through openings cut in partitions. What heat did not work its way through those ducts spread between the joists to warm the first floor from beneath and the upper air in the basement space.

Tenants claimed the building had been unusually warm. The heating system was being worked hard, especially during some below-zero periods in December, and humidity in the basement was undoubtedly quite low as is common in the region during the winter. No log of actual heating system temperatures existed, but typical water temperature entering radiators of a hot water space heating system is 180°F.

It was apparent to investigators that prolonged exposure of joist surfaces to direct contact with the heated radiators caused the formation of pyrophoric carbon which resulted in spontaneous ignition of the joists. The unseen flames then spread horizontally to wall openings leading upstairs, bypassing the first and second floors entirely to turn the cockloft into a time bomb.

“It’s the first time I’ve seen anything quite like that in 28 years on the job,” said Fire Lt. Noble Heller, head of the investigation unit. “It was a good building—well maintained. Nobody inspecting it would have known what was inside those ducts or been able to see what was happening. After a long period of time, the damage was done.”