The Mall Kit

When a large shopping mall fire occurs, it tends to draw media attention. This is primarily because of the heavy life and property risk involved.

Although layouts of shopping malls vary, there are several basic similarities to these structures. The first, and the most severe in terms of a fire hazard, is the common cockloft running above the linked stores. These voids provide a ready channel for fire extension. Fire spread is also enhanced by malls’ large open areas and heavy fire loads.

Water supply can be another problem. Shopping malls are most often built on the fringes of urban centers, and, therefore, hydrants, water mains, and fire stations are not as close as they would be to a downtown area.

Depending on individual building codes, malls may or may not be equipped with sprinklers and standpipes. And, even if fitted with these fire protection/suppression devices, it’s not 100% certain that they’ll be in good working condition when you need them (see “Automatic Sprinklers—Prelude to Disaster?” FIRE ENGINEERING, May 1985). That’s why in mall fires, just as in high-rise fires, fire departments bring their own hoselines and augment the building’s sprinkler and standpipe systems.

Also, if the fire is in the center of the mall, long hose stretches and corresponding friction loss can make extinguishment difficult.

I think we’re all agreed that the best way to mitigate any incident is by pre-planned strategies and hard-hitting tactics. And to execute hard-hitting tactics, you need not only a well-trained firefighting team, but adequate equipment.

An innovative combination of existing equipment and tactics adapted to special circumstances is proving successful in combatting mall fires. Designed by the Del Trail Fire Department in Boca Raton, FL, the mall kit gives the department the capability of placing the interior initial lines between the fire and the most severe exposure, lowering the possibility of having to launch an exterior attack and spreading flames and smoke through security gates and into public corridors. We are also able to flow 500 gpm within two minutes of implementing the mall kit.

MALL KIT DESIGN

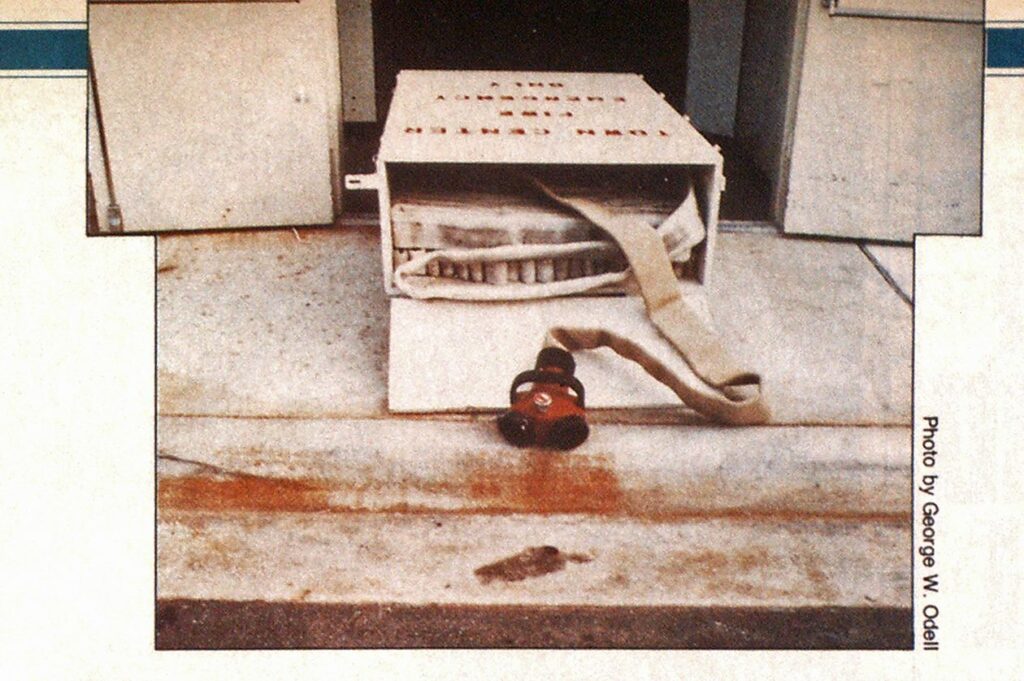

The basic elements of the kit, a hand-pulled box on wheels, are hoses, nozzles, and appliances. The lengths of hose, the number of appliances, and the type and size of nozzles will vary depending on the particular department and/or the particular mall for which the kit is intended. The mall kit discussed here was designed for the Town Center Mall in Boca Raton.

On the botton of the kit are two, accordion loaded, 100-foot lengths of 1 3/4-inch hose (four 50-foot lengths pre-connected). Each 100-foot length of hose is connected to a 1 1/2-inch side tap of a 2 1/2inch water thief; and each line is fitted with an automatic (constant pressure) nozzle.

Connected to the 21/2-inch outlet of the water thief is a 21/2-inch X 1 1/2-inch gated wye. The inlet side of the water thief is supplied by 250 feet of pre-connected 3-inch hose. This length of hose makes up the second and third layers of the mall kit. The final piece of equipment in the kit is a 21/2-inch Siamese, which supplies the 3-inch hose.

The rear wall of the mall kit can be lowered like a tailgate so that the hose can be played out. The kit is packed via the top lid, which is kept locked to prevent unauthorized tampering, as it is stored in the maintenance area of the mall.

The fundamental building block in the operation of this mall kit is pre-planning. The layout of the mall and its square footage; the location of public and service corridors, utility shutoffs, and sprinkler/standpipe systems; hazardous materials (note the location of any drug stores; see “The Local Pharmacy Fire,” FIRE ENGINEERING, September 1984); construction features; available fire department equipment and manpower, all play a part in the setup of the mall kit and the tactics employed by the responding units. Once the mall kit for the Town

Center Mall was completed, our department began intensive training. All training, which includes both wet and dry drills, is conducted before and/or after business hours. Wet drills are done in the mail’s parking lot, with the mall kit and then water called for in a realistic simulation.

The dry drills are done inside the mall with a particular store designated as the alarm location. These dry drills are broken down into job components, with everyone trying all assignments. Our department uses stop-action training, where each job component is explained, related to the total evolution, demonstrated, practiced, and understood. Any participant may stop the operation at any point with a question.

Continued on page 46

Continued from page 44

MALL LAYOUT/CONSTRUCTION

The Town Center Mall is in the shape of a bent arm, with anchor stores at the hand, outside the elbow, and at the shoulder. These three stores total 400,000 square feet. There are 123 tenant stores with public and service corridors. They add 375,000 square feet to the structure for a total of ¾-million square feet of target hazard. The individual tenant stores are typically from 25-100 feet wide and 100-125 feet deep. The rear of each store consists of stock storage, offices, electrical service, employee rest area, and an emergency exit. The fronts of most of the stores are separated from the public corridors by open mesh, rolldown security gates.

There are eight combination sprinkler/standpipe systems, each separate with local Siamese connections distributed around the perimeter of the building. There are 17 hydrants on a looped 10inch main around the inner perimeter road, flow tested at over 2,000 gpm. The ceilings of the stores have a 1-hour rating. Above the ceiling, a common cockloft is divided only where service corridors pass between stores. The roof is parallel cord, roll-bar truss supported Q-decking, with two inches of rigid urethane foam (see Training Notebook, FIRE ENGINEERING, October 1985), tar paper, topped with 1/2-inch of tar and gravel. The public corridors have no ceiling, their roofs are supported with space-frame construction.

MALL KIT/TACTICS TRAINING

In the Town Center Mall, an automatic alarm monitors each sprinkler zone. Our standard operating procedure calls for the rescue truck to drop off two firefighters with a radio at the mall kit storage location before proceeding to the rear of the alarm location.

The two firefighters position the kit outside the mall at a service corridor or public entrance near the alarm location. The first-arriving pumper goes directly to this mall kit location, noting the nearest hydrant.

Continued on page 49

We calculated and then flow tested the mall kit for 500 gpm and 700 gpm (first two lines, and then all four lines). The calculations indicated 500 gpm required 283 psi, and 750 gpm required 368 psi. These pressures violate our department’s guideline of never exceeding 200 psi. However, we ran a field test to determine the feasibility of using these pressures, and the chief, assistant chief, training officer, and chief engineer (head mechanic) observed the test and determined that there was no abuse to the equipment and approved the evolution.

The actual test results were: 750 gpm flowing at an engine pressure of 360 psi, 1,700 rpm, with the pump in pressure, and residual hydrant pressure of 75 psi, for a net pump pressure of 285 psi. Pressure at the nozzles was 100 psi.

Continued from page 46

The truck officer and chauffeur enter the mall with air packs, forcible entry tools, and a portable radio to size-up and search for the fire location. The engine chauffeur prepares to reverse lay parallel 3-inch lines from the mall kit’s Siamese to the nearest hydrant. The two firefighters drop the tailgate of the mall kit and hook up two 3inch hoses from the pumper to the Siamese, then stand fast awaiting orders from the truck officer.

If the mall kit is called for, the engine chauffeur lays the double (parallel) 3-inch lines to the nearest hydrant, hooks up a 6-inch soft suction to the hydrant’s steamer connection, and charges the pump. He then breaks the lines and hooks them up to the pump discharges and awaits the order to start water.

The two firefighters with the mall kit pull it into the mall, playing out the 250 feet of 3-inch hose as they report to the truck officer’s location. At the front of the fire store, they pull out the rest of the 3-inch hose, the water thief, and

the two 100-foot lengths of 1¾inch attack lines. At this point, the mall kit is ready for water, and the officer radios for the lines to be charged. Both lines are assigned to the fire store; 500 gpm should be enough for a quick knockdown.

The second arriving engine is assigned to carry in two 11/2-inch, 150-foot handlines, hook them up to the gated wye, and check adjacent stores for fire spread.

The management of the mall realized the value of having such a kit in their complex, and agreed to purchase the necessary equipment for the fire department. The cost came to about $3,000.

The mall management even presented the mall kit concept to fire departments in Kentucky, Tennessee, and Texas, where similar construction is under way.

While a mall is being constructed, the cost of the kit may be absorbed by the building management as an unscheduled finishing expense. Existing malls implementing the kit may be able to apply for reduced insurance rates because of enhanced fire protection equipment.