Pump House Provides Quick Supply Of Water From Ice-Covered Lake

features

A heated “quick water dump” pump house with both submersible 700-gpm pump and drafting facilities has solved the problem of getting water from Lake Winnebago in Wisconsin when thick ice covers the lake.

The primary water supply for the Town of Calumet Volunteer Fire Department, a rural department on the southeast shore of Lake Winnebago, has always been the lake. Although Winnebago provides an unlimited water supply, the lake has some intrinsic problems.

To get water from Winnebago, a portable pump, two lengths of hard suction: a length of 2 ½-inch hose, a floating dock, a nozzle, and a portable generator and lights for night fires had to be dispatched to the lake.

Winter provided a major problem. The ice on the lake at times becomes 30 inches thick. A good man with a sharp ice chisel can puncture a hole in 10 important minutes.

Other problems were congestion around the portable pump site, too many men needed for the drafting operation, too much equipment, complicated setup, no radio contact with the rest of the department (except by word of mouth), a portable that would not start, running out of fuel, noise and the danger of men falling in the lake.

This past year, we started our “quick water dump” pump house project by burying an 18-inch culvert conduit 6 feet below the normal water level and extending it 24 feet into the shore. Since there is a boat channel at our location, we did not have to extend the conduit any distance into the water to obtain an adequate water supply. A precast cement manhole, to be used as a reservoir, was placed at the end of the conduit up to ground level.

Pump house built

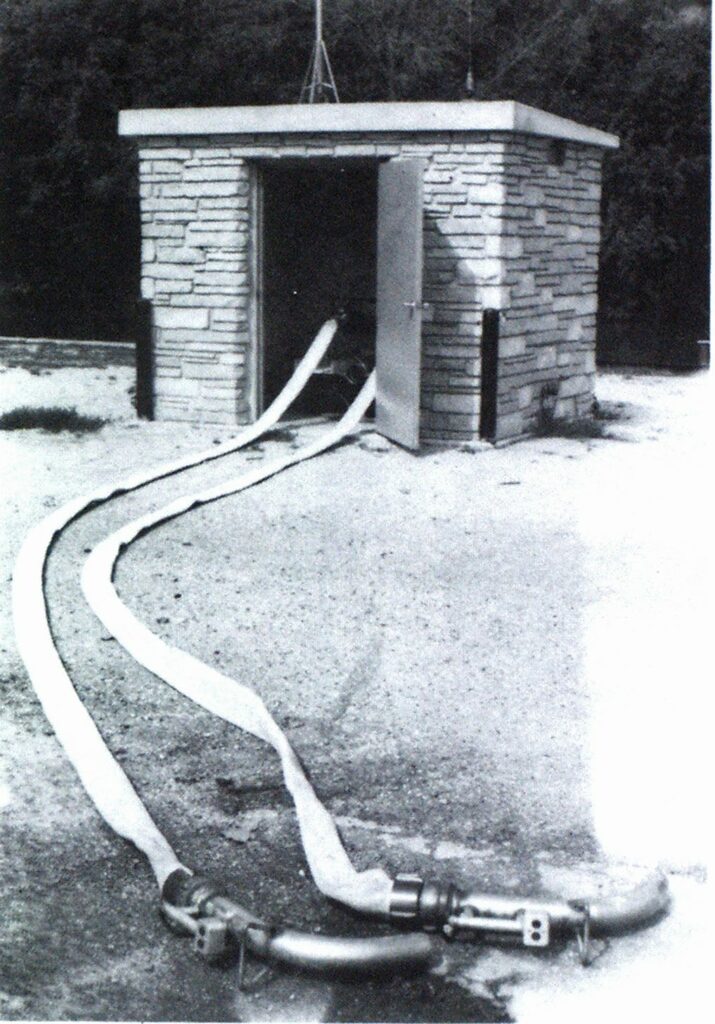

An 8 X 10 X 9-foot cement block building, well insulated, was built over the manhole. The building has a concrete flat roof and floor. Lannon stone veneer was used to make the building complementary to the park surroundings. An exterior steel fire door was installed to make the build as vandalproof as possible. A manhole-size opening is in the roof directly over the manhole for the installation of pumping equipment, standpipes and maintenance.

A 220-volt, 200-amp, single-phase, electrical service was installed and the wires were buried from the line pole to the pump house to avoid any overhead obstructions.

Two 2 ½-inch standpipes were installed in the manhole reservoir and run through two opposite outside walls. These two standpipes provide drafting access to the water supply and they are capped when not being used.

One 4 ½-inch standpipe, accessible through the building doorway, was installed for drafting by larger pumpers.

A 12-inch well casing, with holes bored in it, was pressed 5 feet below the bottom of the reservoir to house a 700-gpm submersible pump. A 5-inch outlet standpipe is connected to it. The top of this standpipe was fitted with a tee and a pair of 3-inch, 90-degree gate valves.

Operation of valves

Two 30-foot lengths of preconnected 3-inch hose are in hose troughs in an accordion load. Each 3-inch line has a gooseneck tank-fill nozzle at the end. The valves are operated by individual, 9-inch stroke, hydraulic rams. The hydraulic pressure is produced by individual hydraulic pumps powered by 12-VDC electric motors. The hydraulic rams can easily be disconnected from the valves by removing U-shaped pins in case of a malfunction. Operators control the valves with two push buttons, “closed” and “open,” mounted on each tank-fill nozzle. The three wires for operation of the electric motors are strung inside each 3-inch line from the motor at the valves to the fill nozzles. This was done to avoid the possibility of entanglement of external wires. Limit switches were installed on the valves to provide the lock to lock, blind control needed for our type operation.

A 12-volt electrical system was chosen over a 120 or 240-volt system to prevent the chance of electrical shock to our people. The submersible pump runs continuously during pump house operation.

A 140-ampere-hour battery was installed to provide the 12-VDC supply. A unique charger was installed to keep a trickle charge (1.5 amps) always on the battery and a fast charge (up to 400 amps) during pump house operation.

A 12-volt radio was installed in the pump house to maintain the communications link to our trucks and firehouse even during a commercial power failure. A mercury vapor lamp with a switch was installed for night operation.

A milk house heater keeps the pump house temperature above freezing during the winter. The radio, mercury vapor, and interior lights are turned on with a door opening, activated switch. Many small amperage circuit breakers and a magnetic motor starter protect the equipment.

The building is landscaped to provide a 300-degree paved access. Two roads from different directions, allow an orderly in and out traffic flow.

One man can do what it used to take three to six men to do—and in less time. A 350-gallon tank can be filled in 30 seconds. A 1500-gallon tanker takes two minutes.

Our hydraulically operated gate valves with nozzle control could be used by a department with a cistern or hydrant supply for tankers. The 12-volt electric over hydraulic pumps, 9-inch rams, and hydraulic hose are from Merc Cruiser’s power trim package for boats, obtained as service parts. If threephase power had been available, the cost of the pump and starter would have been considerably less.

Advantages of pump house

In summary, we have eliminated our water supply problems with a permanent, low-cost “quick water dump” pump house. Manpower needs have been reduced by 75 percent, providing a least three more men at the fire scene or wherever needed.

The pump house frees our portable pump and light plant for setting up a second water supply closer to the fire if needed and no longer is there a period of time with no water supply. We have a pump that has 200 percent more capacity than any portable pump used in the traditional method, and it starts delivering at the turn of a switch and the pushing of a button.

The Town of Calumet Volunteer Fire Department has 55 members and covers about 50 square miles with one 750-gpm pumper, a 500-gallon minipumper and two tankers with capacities of over 1500 gallons. The department has mutual aid agreements with four surrounding fire departments and has organized local farmers and businessmen to haul 11 portable, 350-gallon tanks with their pickup trucks.