By Joe Knitter

Although there are many types of restaurants across our country, fast-food restaurants are probably the most common and most visible. In 2014, McDonald’s, Burger King, and the stores of the Yum Food Brand (KFC, Taco Bell, and Pizza Hut), accounted for more than 39,900 locations throughout the United States. All things considered, it can be surmised that fast-food restaurants can probably be found in nearly every fire department’s first-due or mutual-aid response area. Their presence and daily operations cause very little concern for the fire service, but what happens when they are on fire does. Most of them, with the exception of those in malls and other shared locations, are free-standing buildings constructed of the latest in lightweight, engineered lumber technology and techniques.

Causes of Fires

As would be expected, cooking is the most prominent cause of fires that occur in fast-food restaurants. However, it is not always the simple act of cooking that causes the fire; it can often be more specifically related to the materials or equipment used in preparing the food. Some firefighters automatically assume that the cause of a fire in a fast-food establishment is associated with the kitchen hood ventilation system.

RELATED FIREFIGHTER TRAINING

Lessons Learned from a Taco Bell Restaurant Fire

What Would You Do? Fast Food Restaurant Fire

December Simulation: Fast Food Restaurant Fire

Carbon Dioxide: A Hidden Danger for Firefighters

This was the case in Boston on August 29, 2007, when two of the department’s firefighters perished while making an initial attack on a fire in a Mandarin-Cantonese restaurant in the West Roxbury area of the city. The restaurant was not the free-standing, lightweight design structures typical of these occupancies. Investigators found that the fire, which had eventually come to involve the entire concealed area above the drop ceiling, originally started in the kitchen hood ventilation system. Reports indicated that this restaurant had been cited numerous times for housekeeping issues related to the hood system, such as placing aluminum foil over a food preparation table to catch smoldering grease drippings as they fell from the ceiling. The establishment had corrected all prior code violations and maintenance requirements cited by the fire inspectors, but both the code enforcement and maintenance services failed to notice and cite that the exhaust system materials and installation were noncompliant.

Equipment failure must be considered when dealing with fires in fast-food restaurants. Most of the equipment used in food preparation, especially the deep fat fryer-type appliance, operates with temperatures in the 200-390°F range being provided by 208V, 240V or 480V three-phase electrical service or similar natural gas-fed appliances working with burners producing in excess of 90,000 British thermal units. Most (if not all) deep fryer-type appliances are equipped with mechanical or electronic temperature controls designed to continuously sense and adjust the temperature of the oil to prevent overheating conditions, but, like anything, these mechanical devices are subject to failure (photo 1). A simple malfunction in one of the temperature controllers could mean the eventual autoignition of the cooking media (vegetable oils), which have a wide range of flashpoints ranging from around 201°F to more than 540°F, as reported by safety data sheets (SDS).

Also, consider arson. The fire that took the lives of Lewis Mayo III and Kimberly Smith of the Houston (TX) Fire Department on Valentine’s Day, 2000, was an early morning fire started by teenagers to cover up a planned burglary. The fire spread unimpededly into the concealed attic space and finally vented through the roof. The first impression of the arriving Houston Fire Department personnel was that they had a fire involving a ventilation flue; it was reported that flames were seen coming from the roof and shooting five to eight feet into the air and about five feet in diameter. Unfortunately, the fire had gained a hold of the attic space, and Firefighters Mayo and Smith were inside the building when the roof suddenly and catastrophically collapsed, trapping them.

Lightweight Construction

Engineered lumber products are by no means new to the construction industry; there are reports that plywood was used in Russia prior to the 20th century. Plywood is often referred to as the original engineered wood product because it was one of the first to be made by bonding together cut or refashioned pieces of wood to form a larger composite unit stronger and stiffer than the individual parts. The first U.S. patent for plywood was issued on December 26, 1865, to John K. Mayo of New York City. It did not gain in popularity in the American market, however, until it was “re-introduced” in 1905 in Portland, Oregon, as the area was preparing to host the World’s Fair as part of the 100th anniversary celebration of the Lewis and Clark Expedition. By 1907, the Portland Manufacturing Company was making 420 panels a day.

In the late 1970s and early 1980s, the principles behind the design of plywood gave rise to what today is known as oriented strand board (OSB). Instead of solid sheets of veneer, OSB is made of small wood strands glued together in cross-laminated layers. Cross-laminating layers of wood veneer is said to improve the inherent structural advantages of wood by distributing along-the-grain strength in both directions. Although structurally sound under ideal and laboratory test conditions, the performance of engineered lumber products when subjected to high-heat conditions or direct-flame impingement remains questionable.

According to the Fire Facts Guide produced by the Weyerhauser Corporation, “One-dimensional charring tests of structural composite lumber products, including laminated veneer lumber, parallel strand lumber, and laminated strand lumber confirmed that charring of these products in the standard fire-endurance test may be considered comparable with solid wood.” The obvious question that begs to be asked is . . . when was the last time you fought a one-dimensional fire or responded to a report by the proverbial Mrs. Smith that her neighbor’s house was being charred? If they may be considered comparable, I guess that also means that they may not be considered comparable as well.

A similar publication from the Georgia-Pacific Company titled, Important Fire Safety Information Regarding Fire Rated Building Assemblies and Components of Fire Rated Assemblies, contains statements that remove any question as to the reliability of fire testing: “Because actual fires vary both from lab conditions and from fire to fire based on a wide variety of factors . . . fire tests are not representative of actual fire conditions” and “Fire tests do not assess individual materials or products for their fire-resistance characteristics” and, finally, “In the event of an actual fire, you should immediately take any and all action necessary for your safety and the safety of others without regard for any fire rating of any product or assembly.” Really? Someone not in the fire service has finally realized and admitted that products being tested in laboratories are not going to perform in the exact same way as when under real fire conditions.

The wide variety of engineered lumber products in use in today’s building construction is extensive; there are too many to cover in this article. Engineered sheet products like plywood and OSB; floor and roof structures made of truss-assemblies and engineered I-joists; and extended overhang and parapet assemblies constructed wholly of trusses rely primarily on their proper design, construction, and field installation (photo 3).

As veteran Miami-Dade (FL) Fire Captain Bill Gustin recently stated at a conference I attended, “While we no longer have vertical balloon construction, we certainly have horizontal balloon construction.” What he is referring to is the extensive lengths that engineered I-beams and trusses are able to run without fire stopping or barriers. I have witnessed installations that ranged from 30 feet to 40 feet (photo 4).

An area most often ignored is fasteners that hold the structures together. Designed and tested to hold the structural components together under ideal laboratory conditions, the question that arises is how they will perform and hold up under high-heat and direct flame-impingement conditions. Gusset or truss plates are known to fail as they accumulate the heat from the fire, which causes pyrolysis around the “teeth” of the fastener and the eventual disconnect from the wood they are holding together. Once the fastener releases from the truss, gravity takes over, and the truss is subject to failure and collapse. Like a house of cards, once the trusses begin to fail, they continue to do so until there is a catastrophic collapse because the support structure was designed as a system, and the system depends on all of its components to maintain its structural integrity.

Operational Expectations/Tactical Approaches

Statistics reveal that fires in these buildings occur rather uniformly throughout the day with a slight uptick in the 9-11a.m. and 7-8 p.m. hours, which can be attributed to the increase of customers being served during the breakfast/lunch and dinner hours. However, the ever-increasing popularity of 24-hour accessibility to fast-food leaves the American fire service with the duty of ensuring the safety of any employees or customers still inside the restaurant for fires that occur outside of these peak-time hours. Knowing your response area and the hours of service of the location to which you are responding is extremely important when performing your prearrival size-up and eventually making fireground decisions.

Most of the operational expectations and tactical approaches are common sense and applicable to most any structure fire response. However, there are industry-specific considerations we should be familiar with, especially when dealing with ventilation systems, presence of pressurized and refrigerant gases, lightweight construction, and other unique hazards. Following are some of the operational expectations for which you should be prepared at fires involving these occupancies:

1. Expect the unexpected. First-arriving units in the Houston fire referred to above assumed the fire was involving the ventilation flue based on the visual observation of fire showing “through the roof” on arrival. Rapid changes in the fire proved otherwise.

2. Expect four types of fires:

a. Kitchen (occupied areas)

b. Exhaust hood/ductwork (occupied concealed areas)

c. Cockloft/attic (concealed areas)

d. Grease residue burning on the roof. Fire/building codes require a noncombustible collection container on the roof to collect the runoff from ventilator fans. More often than not, combustible containers are substituted.

3. Expect to access the kitchen through a rear door; entering here may avoid a long, difficult stretch around counters, tables, and other obstacles.

4. Expect to check for fire in concealed spaces immediately upon entering. First-arriving firefighters in the Boston incident mentioned earlier observed fire in the ceiling above the exhaust hood with light smoke conditions in the kitchen. Reports from the companies on the roof indicated the roof felt spongy, and the driver of the responding ladder truck noted heavy gray smoke pushing from the cupola on the building.

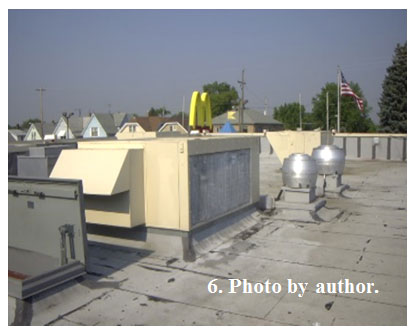

5. Expect early collapse accelerated by lightweight roof construction and heavy air-handling and ventilation units on the roof.

6. Expect large gas supply lines. Early control of the utilities is paramount in making sure fire spread is limited. Most ventilation hood extinguishing systems are designed to shut down the electrical or gas supply when activated, but fires involving the concealed spaces can compromise the overall supply to the building.

7. Expect a violent reaction if you apply water directly to burning cooking oil or grease. As we’ve been taught since our youth, oil and water don’t mix!

8. Expect to carefully check for extension and examine the entire run of exhaust ductwork, especially where it may penetrate a combustible wall, ceiling, or roof.

9. Expect to take a line to the roof to control extension onto roofing materials. However, training and discipline should emphasize that the application of water should be on the roof, not through the roof to the interior.

10. Expect to notify and interact with your local health department or commissioner/sanitarian as a way to provide good customer service to the restaurant and get it reopened for business.

In addition to the expectations listed above, here are some Tactical Tidbits I can offer from personal experience:

Don’t commit apparatus or attack lines until it has been determined exactly where the fire is and the best way to enter. Fires involving the concealed space can jeopardize the integrity of the roof, causing the heavy HVAC equipment to compromise the roof and cause it to collapse. First-arriving companies must conduct a thorough 360°-plus size-up–360° around the entire building, plus what is above your heads and below your feet. Some of these buildings have basements. If you encounter a fire that involves the concealed space, it is imperative that you make a careful evaluation of the overhead dead load before committing to a means of ingress.

Locate the kitchen exhaust fan power supply, and shut it down, once again ensuring that the energy source is shut down as well. Fires venting from the ductwork can impact the refrigerant lines of air-conditioning systems, jeopardizing the integrity of the lines, which could result in the production of hydroflouric and hydrochloric acids along with smaller amounts of chlorine and phosgene gases.

Locate the fixed suppression systems; after careful consideration of the fire’s location and the impact of the extinguishing system will have, discharge to extinguish any remaining fire on the cook tops or in the hot oil fryers. As mentioned earlier, be careful that no water spray contacts these appliances.

On determining the location of the fire, advance the initial attack line into the interior of the building either as a primary attack line or as a backup line to a dry chemical extinguisher used to extinguish the duct fire. The extinguishers or the attack line can be operated into the kitchen ductwork through clean-out openings or access holes in the ductwork to limit extension.

Keep in mind the residual damage and cleanup that will be needed after using a dry chemical extinguisher. The entire food preparation area may have to be sanitized and food products will have to be discarded because of the risk of contamination.

If using water as the extinguishing agent, remember NOT to allow it to be discharged down into the ductwork, especially considering the weight of water and the impact it can have if it accumulates in the ductwork.

You must carefully salvage and overhaul, including making a thorough check for extension to search for any hidden fire. If you can’t see it, open it up.

You can’t salvage ruined stock. Don’t sacrifice firefighters’ lives for stock or property that is already lost. Food products damaged by smoke or heat will be discarded.

Fires suspected of being in the void spaces above ceiling tiles require quick action. From the protection of a doorway, lift a ceiling tile with a pike pole and scan the entire area with a TIC to detect and assess the level of any fire involvement. Many commercial ceiling tile assemblies have insulating properties and can mask heat signatures from TICs. Often, the steel grid work will be the first item to show heat buildup in the concealed space. Use your tools and technology to thoroughly assess the fire’s location and extent.

Create a safer work environment by forcing all of the doors open, in essence “softening” the building for emergency egress, if necessary. Try to avoid taking the glass out of doors and windows unless absolutely necessary for ventilation. Once you take out the glass on the door, you lose the ability to control the flow path.

Opponents of interior fire attack will say, “If there’s no threat to human life, stay out.” I am in no way advocating that an interior attack can’t be initiated on these buildings. However, I will say that it must be on your terms and conditions and not those of the media, the property owners, or the public. Remember, there is no property worth the life of a firefighter. If all occupants are out of the building and the risk to human life has been removed, a cautious, interior attack, supported by a continuous size-up can be initiated. Free-standing, lightweight constructed buildings occupied as fast-food restaurants are everywhere, and more are being built every day. The good fireground commanders focus on understanding how they are built, how fires start in them, how they come apart when attacked by high-heat conditions or direct flame impingement, and what operational expectations and tactical approaches are appropriate.

Remember, it is easier to justify to a property owner why you went defensive than to explain to a grieving family why you didn’t.

BIO

Joseph Knitter, a 34-plus-year veteran of the fire service is the fire chief for the South Milwaukee (WI) Fire Department, where he has served the past 30 years. He has an associate degree in fire science and a bachelor’s degree in fire service management. He is a graduate of the Executive Fire Officer Program through the U.S. Fire Administration-National Fire Academy. In addition, he is a Wisconsin-certified Fire Officer II, Fire Instructor I, and Fire Inspector, and is certified by the National Board on Fire Service Professional Qualifications as an Incident Safety Officer. He is a member of the FireRescue magazine and FDIC educational advisory boards. He teaches fire certification classes for Milwaukee Area Technical College and incident management for the State of Wisconsin, Division of Emergency Management, and lectures on various topics throughout the area.