By CHRIS GREENE, MARK COONS, AND HUGH HOAGLAND

Structural firefighting personal protective equipment (PPE) undergoes extensive testing to ensure your safety during the most extreme heat situations you will face in a structure fire. National Fire Protection Association (NFPA) 1971, Standard on Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting, mandates that several thermal impact tests be conducted to ensure one thing—you come out of that structure fire safely.

But what does safe mean? Does it mean I “feel” safe? My gear didn’t catch fire? I didn’t get burned? Quantifying safety can be a deep and never-ending rabbit hole to venture down. Ensuring that your PPE matches the thermal hazards has been the academic focus of many, and I am glad someone took the time to do this. Let’s review three of the most familiar PPE thermal performance tests and how they ensure our safety.

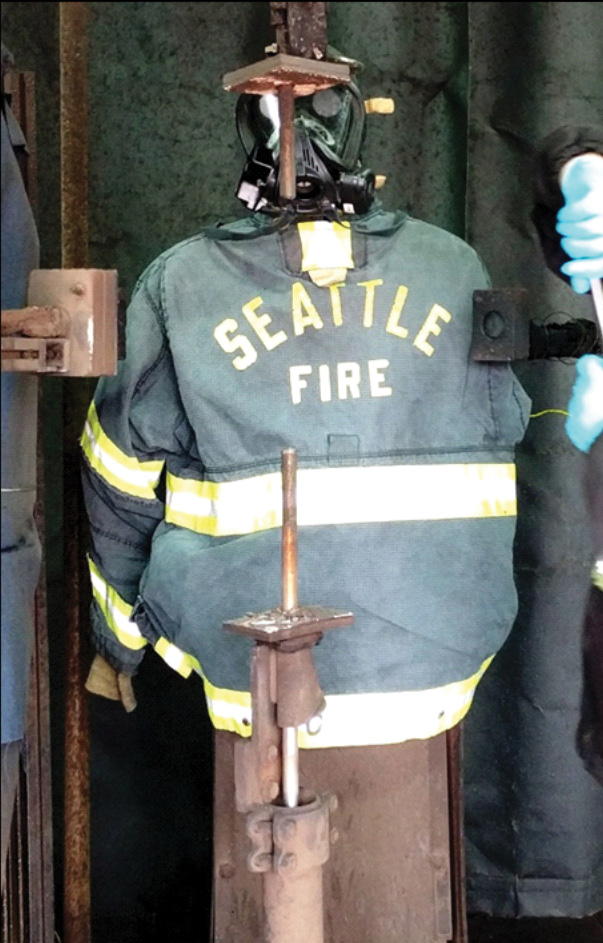

(1) This personal protective equipment is mounted for arc flash testing. It has 18 inches of 20Kv/8Ka arc. (Photos 1-5 by Chris Greene.)

Thermal Protective Performance (TPP) Test. This test serves as the benchmark for how our gear protects us during flashover conditions where temperatures can reach as high as 1,800°F. Associated with this test is a TPP rating number that NFPA 1971 mandates should not be less than 35 and (generally) not more than 50. This minimum number (35) divided in half (17.5) represents the number of seconds your gear will protect you from receiving a second-degree burn in a flashover space. This small-scale test uses both radiant and convective heat but at a specific heat flux, so if the predicted burn time is 35 seconds at one heat flux, higher heat fluxes might be better or worse, depending on the level. Suffice it to say, our gear is very protective. It is worth noting that the TPP rating applies only to the turnout gear fabric and does not speak to the total PPE ensemble, which includes undergarments that may increase your protection.

(2) Snapshot of the arc flash.

Flame Resistance Test. Also known as the Vertical Flame Test, PPE is subjected to direct flame for 12 seconds. Once the flame is removed from the flame source, it must self-extinguish within two seconds, and the remaining char length cannot exceed four inches.

Forced Oven Test. Using a convection oven, the PPE is subjected to a temperature of 500°F for five minutes. The material should not burn, melt, drip, or shrink more than 10 percent.

Boiling It Down

To ensure your safety, structural firefighting gear is designed to do two things well: resist burning and reduce the amount of thermal energy being transferred to your skin. The three most basic of the 40-plus tests performed per NFPA 1971 involve how much thermal energy the gear can absorb before a firefighter receives a second-degree burn. For flashover conditions, the results are around 17 seconds; for lower temperatures (500°F), around five minutes. If my gear ignites, it will stop burning once I get away from the direct flame.

The fire service has done much to ensure that first responders understand the hazards associated with structure fires. NFPA 1971 compliance ensures that your gear matches these hazards, which is key for your safety. However, these tests are specific to the thermal hazards consistent with structure fires and are the results that do not include the thermal hazards inherent with an electrical arc flash.

PPE Performance During Electrical Arc Flash

As the Seattle (WA) Fire Department (SFD) Vault Response Team (VRT) was being developed, the question of PPE was paramount. Specifically, how do we ensure that our PPE matches the hazards inherent with high-voltage emergencies? There are two basic hazards to consider: electrical shock concern (not addressed in this article) and the arc flash hazard, which is not as well known but results in, statistically, the greatest number of injuries associated with all electrical emergencies.

Closing this PPE information gap was daunting. NFPA 1971 does not address hazards associated with the thermal energy from an arc flash. Arc flash incidents generally resolve in less than one second, but the thermal energy can be in excess of 10,000°F. NFPA 70E, Standard for Electrical Safety in the Workplace, provides language that addresses PPE for workers who may—in the course of their duties—encounter an arc flash event. The duties of our VRT would put us in this very situation.

The testing requirements are spelled out in American Society for Testing and Materials (ASTM) 1959, Standard Test Method for Determining the Arc Rating of Materials for Clothing, for fabrics, and ASTM F2178, Standard Test Method for Determining the Arc Rating and Standard Specification for Eye or Face Protective Products, for head protection. We thought, “Great, we’ll just contact the SFD’s PPE provider and get the information.” The SFD PPE provider responded by saying it didn’t test gear for electrical arc flash hazards and neither did anyone else in the fire service PPE industry. “It’s just not a hazard we expect a firefighter will encounter.” This is when we realized what we were up against.

Arc flash hazards are a primary concern for the SFD’s VRT, and matching its PPE to this hazard is a basic expectation for team members, as required by Occupational Safety and Health Administration (OSHA) CFR 1910.269 or NFPA 70E, Annex H, which states: “Arc Flash thermal energy is different than structure fire thermal energy. It is shorter in duration but often much hotter than even the worst you will face in a structure fire. Fortunately, the fabric systems used in our gear have been partially evaluated in the development of arc rated flash suits used by workers in just these situations. The advantage with arc flash energy is that most can be reliably calculated making the hazard more predictable. Learning how to read an arc flash label is the next step to understanding these hazards and the PPE requirements.”

The electrical industry identifies and categorizes PPE with regard to thermal energy absorption ability. Electrical PPE falls into one of four categories, and each category has a range of thermal protectiveness. The lower the number or category, the less protection. Each category reflects a specific amount of energy expressed in calories per centimeter squared, or cal/cm2. It is necessary to have structural firefighting gear properly tested by an accredited agency to get this information. This is what we were missing.

(3) The damage to the outer shell of the PPE.

Testing in Canada

In December 2017, we (Mark Coons and Chris Greene) traveled to Toronto, Ontario, Canada, to have our PPE arc tested. Coons, a 20-year SFD veteran, was anxious to look closer at how our gear would perform. He provides a unique perspective on how line firefighters can better understand arc flash hazards and their PPE. Coons said, “SFD’s VRT was beginning to take shape, but there were still a lot of unanswered questions. In fact, most of us didn’t think the program would get beyond the awareness level. I agreed to go to Toronto to the only arc flash testing facility in North America to witness first-hand how our structural firefighting gear would stand up to intense, electrical energy in the form of an arc flash.

(4) There was no damage to the inner barrier.

“Leading up to the trip, I was asking myself, ‘Why would I want to go and watch them test our gear for something that I’m never going to see in the field?’ The answer really didn’t become clear to me until Captain Greene and I were back in Seattle with the Toronto trip well in the rearview mirror.” The data we captured provided concrete evidence of just how much energy we may face given the VRT’s new expectations. Additionally, it gave us confidence in our gear and training in addressing high-voltage emergencies. Before this trip, we had no idea of how our gear would perform, but now we understand precisely what to expect. The guessing was over.

(5) There was no damage to the Class B shirt mounted under the PPE.

Post-Testing

Fast forward six months; our group of firefighters at Station 25 began to realize that the SFD, along with Seattle City Light (SCL), was legitimizing the need for a group of electrical fire emergency experts within the SFD. Buy-in happened after listening to a couple of SCL officials excitedly describe the value to them and their customers (big businesses) when our group mitigates fires in downtown network electric vaults and manholes.

Eight months after our trip to Toronto, the city and the union agreed on our deployment model; we are now recognized as the subject matter experts for all emergencies that involve high-voltage electricity. The SFD—through the VRT—has introduced new standard operating guidelines, policies, dispatch-type codes, and training modules geared toward better addressing electrical emergencies. The VRT is expected to understand these hazards, offer assistance to the incident commander, and assume an offensive posture when it can be done safely. The detailed training gives us confidence in this new expectation of our team. Understanding how our PPE will perform was fundamental in getting our members to commit to this endeavor. The value of witnessing our gear being tested brings the SFD a new level of confidence and security knowing that, if we were subjected to a typical arc, our gear would more than protect us.

PPE is important; what we wear around the station and under our turnouts makes a difference. Extra protection such as fire resistant-rated T-shirts and thermal barrier uniforms provide an extra layer of confidence we are not willing to do without. The SFD is now evaluating how to keep our team even safer though use of specialized PPE, day uniforms, and undergarments.

Working with the Experts

Arc flash testing and certification must be performed in a facility certified to perform this process. Kinectrics Laboratory, one of the world’s leading research and engineering firms providing engineering, research, and testing for the nuclear power industry and electric utilities, is also the first lab to provide accredited arc flash testing. At its facility in Toronto, studies found that the energy needed to safely create an electrical arc and provide performance data was the same data recognized by the NFPA, ASTM, and OSHA.

This process was shepherded by Hugh Hoagland of ArcWear, an international consultant for arc flash, flash fire, and textile testing for the electrical industry. Hoagland and Kinectrics work on the ASTM and the International Electrotechnical Committee (IED) standards for arc flash, which tends to feed the International Organization for Standardization standards. Formerly an organic chemist, Hoagland spent four years at LG&E Energy researching and consulting for utilities all over the United States. For the past 24 years, he has performed more than 200,000 arc flash tests at Kinectrics High Current Lab and at the Kema High Power Lab, researching arc flash behavior and doing accredited arc flash testing of PPE from fabrics to fall protection. Hoagland has done many tests on self-contained breathing apparatus devices at nuclear sites to ensure structural firefighting gear would be protective, showing that it would not contribute to injury in arc flashes up to 40 cal/cm2.

How Does Our Gear Fail?

Generally, your gear will fail in one of two ways: (1) It will separate, split, and crack, or (2) it will simply fail to insulate you from the heat source. In the end, both allow thermal energy to transfer to your skin. Your PPE is made up of knit and woven materials. Each responds differently to thermal impact, but once that energy is transferred to your skin beyond two calories per cm2, you will receive a second-degree burn.

After two days of testing and data analysis, our gear was placed into Category 4—Hazard Risk Category with a specific arc flash rating of 62cal/cm2. For our VRT and the electrical industry, this is an extremely good number from a PPE standpoint. More importantly, we finally have a certified rating for our PPE as provided by Kinectrics Laboratory and ArcWear. However, this is recognized only for PPE that has been through this vetting and certification process. If your PPE provider does not provide an arc rating for the gear, you cannot assume its protection based on similar gear. The certification process is mandatory. So, the next time your PPE contract is being reviewed, ask each vendor if it can provide an arc rating for its PPE.

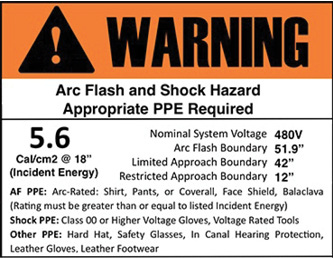

Arc Flash Labels

Arc flash labels provide warnings for when an arc flash hazard may be present. These labels provide the information needed to ensure your PPE matches the hazard. Following are the seven key pieces of information provided by an arc flash label:

Warning/Danger header. A Warning header is generally orange and often indicates either voltages less than 600V or an arc flash incident energy hazard of less than 40cal/cm2. A Danger header may indicate voltages above 600V and potentially too dangerous to enter the space without first deenergizing the hazard. Some companies also use Danger for energy greater than 40 cal/cm2.

Arc flash boundary. This is the minimum distance a person must maintain to avoid a second-degree burn if not wearing proper PPE that matches the arc flash incident energy. A second-degree burn will occur typically when bare skin is subjected to 1.2 cal/cm2 heat. The point at which a worker must don arc-rated PPE is if equipment is exposed or being interacted with in certain ways.

(6) A typical arc flash label. (Photo courtesy of www.arcflashtraining.net.)

Incident energy. The amount of thermal energy produced from an arc flash, expressed in cal/cm2, within the arc flash boundary.

PPE requirement. This identifies an arc flash category of PPE as well as some specifics on PPE requirements—i.e., long-sleeve shirts, insulated gloves, and so on.

Shock hazard. The voltage of the hazard.

Limited approach boundary. The minimum distance that an untrained person must maintain from the electrical shock hazard.

Restricted approach boundary. The point at which a trained person must don proper arc flash and shock hazard PPE with regard to the electrical shock hazard.

Keeping your crew safe when you have a fire that involves an electrical space necessitates that you understand some of the key indicators. Power loss in the area/building coupled with smoke, fire, or an unknown odor from a basement are signs that you may have an electrical fire. During building inspections, look for arc flash labels and understand what they mean for the safety of you and your crew. A locked door with a sign reading “HIGH VOLTAGE” should never mean “GET THE IRONS.”

The process of understanding how the fire service industry’s gear performs under arc flash conditions has begun. Working directly with experts will ensure that we stay on the proper course.

Authors’ note: Thanks to LION for donating much of the PPE for the testing performed by ArcWear and Kinectrics. Their assistance has been invaluable.

CHRIS GREENE is a 25-year fire service veteran and a captain with the Seattle (WA) Fire Department (SFD), assigned to Engine Company 25, which is part of the Vault Response Team (VRT) stationed in the Capitol Hill neighborhood. He created the VRT within the SFD while working closely with Seattle City Light personnel to identify hazard gaps in fire department equipment and procedures for all emergencies involving high-voltage electricity.

MARK COONS is a 21-year firefighter/emergency medical technician for the Seattle (WA) Fire Department assigned to Ladder Company 10 in the Capitol Hill neighborhood. He is also a member of the VRT.

HUGH HOAGLAND is a senior consultant at ArcWear, an arc flash and textile testing company, and senior managing partner at e-Hazard, an electrical safety training company.