By Leigh T. Hollins

Part 1 (November 2018) outlined the gasoline tanker trailer’s characteristics, construction, features, and components (photo 1). Also mentioned was that the initial call to a gasoline tanker incident will get your attention and increase your adrenaline flow because this is a low-frequency/high-risk incident and the visual of such an incident can be spectacular and catastrophic.

During a major gasoline tanker fire in the daylight, the ink-black, thick smoke plume may be hundreds of feet tall and visible for miles (photo 2). A nighttime event may have a visible flame plume that is well over 100 feet tall (photo 3). Both situations are sure to draw a great amount of attention from the public, the press, and your area emergency response agencies, and the emergency resources required can be quite extensive. Less catastrophic/spectacular incidents are also bound to draw an equal amount of attention and may require the same amount of resources or more. These incidents may include gasoline tankers that are not on fire but are leaking or that have been overfilled, an aboveground or belowground tank that has been overfilled, an overturned tanker, or one involved in a collision.

(1) An MC 306/406 gasoline tanker. (Photo by author.)

This article covers how to mitigate various emergency situations involving an MC 306/406 gasoline tanker, provides helpful “points to ponder,” and reviews incidents that have occurred (photo 4). Together, this information will provide emergency responders with an enhanced knowledge that will hopefully result in a safer, more efficient and professional operation and help support the mission of saving lives and property while at the same time keeping yourself and crew members safe .

(2) This I-75 and U.S. 301 tanker crash occurred in 2008. [Photo courtesy of North River (FL) Fire District.]

(3) An I-75 tanker fire that occurred in 1998. (Photo courtesy of Phil Collier.)

(4) St. Johns County tanker, gas station, fuel farm fire in 2011. [Photo courtesy of Joel Sneed, St. Johns (FL) County Fire Department.]

Throughout this article, the term “gasoline tanker” is used generically, and the tactics, strategies, and incidents are based on the MC 306/406 tanker carrying flammable/combustible liquids such as gasoline, diesel fuel, jet fuel, and alcohol/ethanol. The MC 306/406 tanker trailer may carry other regulated or nonregulated products such as kerosene, biodiesel (vegetable/animal fat oil), poisons, and nonpotable water. Many information sources say food products such as milk may be carried in an MC 306/406 tanker, although I doubt that. Liquid food products are typically carried on the MC 407 tanker trailer, which is totally different from the MC 306/406.

“Location” and “Small”

Generally, two words are very important when dealing with a gasoline tanker incident. The first word is “location”; the second word is “small.”

The location of an incident will dictate many things about the incident, whether it is a leak, spill, or fire. This list includes the life hazard to those involved, the general public, and the responders; the type and the quantity of resources required on scene; the potential environmental damage; the disruption of area transportation routes; the physical size of the incident; the potential exposures; and many more factors.

Unfortunately, we cannot control the location of such an incident. It will happen where it happens, and we must be prepared no matter where that may be. It is also possible that your agency, local municipality, county, or even region cannot provide the resources to mitigate a large-scale gasoline tanker incident and that what is going to happen is going to happen. You can mitigate only the end result of such an incident. An example would be a gasoline tanker that overturns and spills thousands of gallons of gasoline that ignites. The burning gasoline runs off into the local river and is carried downstream along the river banks, burning every dock, boat, and house for a half mile. Picture that scenario. It is doubtful that any responding agency could stop such an incident from escalating once it is in motion.

Obviously, fewer resources are needed at the incident scene when the event is small than when it is allowed to grow larger. This “strategy” is usually within an agency’s control, but not always.

Take the case in the previous paragraph, and let’s go back to the word “location.” If that incident had occurred on a bridge over the river and the burning gasoline were spilling directly into the river, chances are that, as stated, not much could have been done to stop it once it was in motion. However, if the same situation had occurred at a location 1,000 feet from the river and the burning gasoline had entered a swale/ditch along the roadway and was flowing to the river, it may have been possible to keep the incident “small” by commandeering a front-end loader or backhoe in the area and stopping the flow with a pile of dirt. Maybe this can even be done with shovels. Both of these approaches have been used many times with success (photo 5). The end result is that you have kept the physical size of the incident “small” and that allowed you to mitigate the incident with fewer resources and less damage, and in less time.

(5) An I-75 tanker crash in Sarasota, Florida, in 2014. (Photo courtesy of Ed Effron.)

Points to Ponder

With all that said, here are some points to ponder that can assist you with your decision making during an incident involving a gasoline tanker.

- The specific gravity of these petroleum products is below 1; therefore, these products will float on water.

- These products have a vapor density well above 1; therefore, the vapors will sink.

- These products have a low ignition temperature (about 400°F), depending on the grade and blend.

- The operation temperature of a catalytic converter on a typical vehicle is more than 400°F, providing an ignition source for petroleum vapors.

- Petroleum products such as ethanol and E-85 (85 percent ethanol) gasoline for “flex fuel” vehicles are polar solvents and mix well with water; therefore, normal firefighting foam will not work well when used as a blanket on unignited spilled fuel or as a firefighting agent. Polar solvents necessitate special foam agents and mix ratios.

- Most areas of the country have one fuel terminal, either a coastal port or a pipeline terminal, from where all of the fuel delivered to that area originates. Therefore, a good rule of thumb is that any tanker traveling away from the terminal location will be loaded and any tanker traveling toward the terminal location will be empty. However, never use that rule as a definite conclusion but rather as a guideline until confirmed. For example, the port of Tampa, Florida, supplies more than 50 percent of the fuel to Florida gas stations. The county I live in is south of Tampa. A tanker headed south on I-75 is very likely to be full.

- Depending on the tanker transport company and region of the country, most tankers that leave the loading terminal are full. Most tankers deliver to one location and then return to the terminal to reload or to their company yard. Some tankers leave the terminal to deliver a “split load,” meaning they will off-load the fuel at two or more locations. The local companies in the Tampa area drop at one location well over 90 percent of the time. This tells me that a tanker will most likely be completely empty or completely full. Check with your local tanker fleet companies to learn of their operation.

- Tankers are usually multicompartment (four or five compartments are most common) and often carry a “mixed load,” such as three compartments of gasoline and one compartment of diesel.

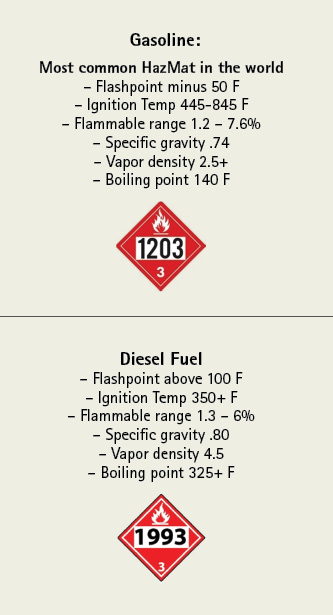

- U.S. Department of Transportation (DOT) placarding requires that a tanker carrying various regulated products (mixed load) be placarded with whatever product was, or is, in a compartment that has the lowest flash point. For example, a tanker with 6,000 gallons of diesel fuel onboard and an empty compartment that contained gasoline will be marked with the placard for gasoline because the flash point of gasoline is less than that of diesel (Figure 1).

- Storm water drains/systems typically lead to either a retention area/pond, a creek/stream/river, or the bay/ocean. Many areas now have stormwater retention areas under parking lots. Some areas have stormwater pipes that lead to a water treatment facility. Know where the spilled tanker products will be traveling to in your area. They may be on fire or traveling toward an ignition source—location, location!

- Because a gasoline tanker is a nonpressure tank, is constructed of aluminum, and has many openings, there is no chance of a boiling-liquid, expanding-vapor explosion (BLEVE).

- How do you know if a fire involving a tanker or at a gas station is a flammable-vapor or a flammable-liquid fire? By the smoke! Vapor fires lack smoke; liquid fires will emit massive amounts of black smoke.

Figure 1. U.S. DOT Placarding for Gasoline, a Flammable Liquid, and Diesel, a Combustible Liquid

Strategies and Tactics

This section of the article reviews emergency situations involving gasoline tankers and offers additional points to ponder as well as strategies and tactics that will enhance your knowledge for safely and successfully mitigating these dangerous incidents.

The U.S. DOT Emergency Response Guidebook offers some great advice under the topics “Resist Rushing In” and “Approach Incident from Upwind and Uphill or Upstream.” You should heed this advice. As first responders, we are trained to act in the case of an emergency. With many hazardous materials incidents, other important steps may need to be taken before any actions are initiated.

As with any incident, life hazard is the priority—the life hazards faced by those directly involved, the general public, and the responders. Another high priority is to identify the product involved in the spill, leak, or fire. When dealing with a gasoline tanker, this will most likely involve obtaining the answers to three questions: (1) Is there product onboard? (2) What is the product? (3) How much product is there (photo 6)?

(6) An overturned tanker on U.S. Hwy 2, in Williams County, North Dakota, in 2018. [Photo courtesy of Williams County (ND) Emergency Management.]

How might we find the answers to these questions? Well, if there is an active leak/spill or a fire involving product from the tanker, the question “Is there product onboard?” is answered. As for the other two questions, let’s consider the following points:

- The first choice is, ask the operator/driver. However, the operator may not be on scene or may be unable to answer questions because of injury or death (as was the case in the incident in photo 6).

- View the placard. (You know from the points to ponder above that this information may be subject to the U.S. DOT placarding criteria.)

- Obtain the bill of lading from the cab of the truck if possible. A bill of lading is a legal document between a shipper and the carrier that details the type, quantity, and destination of the product being shipped. However, this document will confirm only what was loaded onto the tanker.

- Call the company that owns the tanker. Most tanker transport companies have a “dispatch” center that should know the answer to all three questions. When an operator delivers fuel, typically an electronic log is updated and sent to dispatch. In most areas, dispatch will also track their tankers with onboard GPS sensors.

- Use a thermal imaging device to view the liquid level in the tanker compartments.

When a gasoline tanker that is full or substantially full overturns, the tanker cannot be “righted” until it is offloaded. This is mainly because of the weak aluminum construction of the tanker, which may further rupture under the load, which when fully loaded is about 8,500 gallons/60,000 pounds on a single MC 406 tanker trailer. Double-tanker trailers, found mainly on the roads of the western United States, carry even larger loads. When such an incident happens (photo 7), the tanker trailer needs to be stabilized and grounded/bonded. An empty tanker needs to be brought in, and either a private recovery company or the local hazmat team will need to drill a large hole (three- to four-inch) in each compartment that contains product and pump the product out of the overturned tanker. This is a high-hazard operation that requires special training, tools, and equipment.

(7) A tanker rollover on I-75 in Bradenton, Florida, in 2007. (Photo courtesy of Troy Toman.)

The Black Dots

Many responders have seen the black dots but do not know what their significance is (photo 8). Any compartment longer than four feet will have a baffle to control the movement of liquid inside a tank. The black dots in photo 8 mean this tanker has holes in the baffles at the 3 and 6 o’clock positions. This allows liquid to flow to both sides of the baffle when the tanker is on its side. Therefore, such a compartment will need to be drilled only once. Without the 3 and 9 o’clock holes, such a compartment would need to be drilled and pumped on each side of the baffle to remove all the product.

(8). Note the black dots at the 3 and 9 o’clock positions. (Photo by author.)

A fairly common emergency situation involving a gasoline tanker will involve some type of fire under the tanker trailer. The common causes include a smaller vehicle underriding the tanker, vapors released from an underground tank being filled, an overfill of an underground or aboveground tank, a brake fire that ignites the tires, a tire blowout that causes a tire fire, or other situations that may cause a fire under the tanker. Several points will help you understand such emergencies and how to handle some of them. In all cases, at the top of the priority list is to get to the front left of the tanker and activate the emergency valve, which closes all the belly valves on the trailer (photo 9).

- If a smaller vehicle underrides a tanker, the belly valve at the bottom of each compartment is designed to shear off, leaving the valve in place (photos 10 and 11). Know that although the compartment belly valves may stay in place, the damaged piping may contain product.

- The assembly that opens and closes the belly valve, be it cable operated or air operated (photos 10 and 11), will have a heat-sensitive component that will melt at approximately 250°F and close all the belly valves during a fire situation under the tanker.

During an incident in north Florida (photo 12), a brake fire extended to the rear axle tires of this tanker. When such an incident occurs, the emergency valve should be activated and the fire aggressively attacked with class B fire extinguishers (preferred) or a hoseline. Photo 12 shows what will be the result if the compartment is empty. When the fire breaches the aluminum wall (1,100°F-1,200°F), the vapors will flash and quickly burn. Note the baffle with holes at the 3 and 9 o’clock positions. If the compartment above the fire contains product, the product will not allow the fire to breach the aluminum below the liquid level. The aluminum above the liquid (the vapor space) may burn through and allow the vapor on top of the product to burn.

(9). The emergency valve, which closes all the belly valves on the trailer. (Photo by author.)

During an incident like the one depicted in photo 12, an initial strategy may be to “save” the tractor truck (exposure) attached to the tanker trailer by lowering the legs/landing gear of the trailer, releasing the “king pin,” and letting the operator drive the tractor truck away. If it is certain that the tanker trailer is empty, this is a good move. However, if the rest of the trailer, specifically the front compartment (usually the largest compartment on the trailer), has product onboard, the result may be that the landing gear, because it is not designed to support a loaded tanker trailer, may puncture the compartment above, spilling the contents catastrophically. Beware!

(10) Note the shear point of this cable-operated belly valve housing (arrow). (Photo by author.)

(11) Note the shear point of this air-operated belly valve housing (arrow). (Photo by author.)

A Catastrophic Scenario

Below is a discussion of a catastrophic event that is much too common around the country: A fully loaded tanker trailer crashes and burns, endangering the lives of those directly involved, the motoring public, the residents in the area, and the first responders (photos 13-15).

(12) Baldwin, Florida, tanker fire, 2018. (Photo courtesy of John Cooper.)

Considerations. Location is the key. As mentioned previously, we have no control over that. Note: Most areas of the country do not have enough foam concentrate to extinguish a burning fully loaded tanker and to maintain the active foam blanket needed for several hours while recovery workers pump off the hot fuel.

Strategy. Keep it small. That may be easier said than done, but having the “keep it small” mindset will help tremendously if you are able to accomplish that objective.

To burn or not to burn? Again, location will dictate that. If runoff is controlled and there are no exposures or the exposures have already been lost or severely damaged, like the overpass in this incident (photo 15), let it burn. Do not become impatient several hours into the incident and extinguish the fuel. Let it burn all the way down. The product in the compartments will burn down, and the aluminum shell will melt at the liquid level as it burns down. Burn time will be approximately one hour per foot of fuel.

Are there cases when you should extinguish such a fire? Sure. Again, the location will dictate that. In cases where conditions are less than catastrophic, the incident commander will make the decision of whether to extinguish or let the tanker burn.

(13) Fully loaded tanker crash and fire on I-75/U.S. 301 in Ellenton, Florida, in 2008. Resist the urge to apply water to such incidents, as it will probably have a negative effect on the incident. [Photo courtesy of North River (FL) Fire District.]

In 1982, there was a major gasoline tanker fire in downtown Tampa in front of the multistory occupied federal courthouse. Because of this location, the fire, rightfully so, was extinguished. If your action plan calls for an airport crash truck to extinguish a tanker trailer fire, be advised that this may be a difficult resource to obtain unless it is preplanned. A commercial airport will typically need to shut down if the crash fire rescue equipment and crew leave the property, and that probably is not going to be authorized for your tanker fire.

(14) Tanker crash and fire on I-75/U.S. 301 in Ellenton, Florida, in 2008. During this fire, the spilled fuel was allowed to completely burn itself out. [Photos 14 and 15 courtesy of North River (FL) Fire District.] (15) Tanker crash and fire on I-75/U.S. 301 in Ellenton, Florida, in 2008. Note the massive amount of concrete spalling. This overpass is a total loss and the months it took to replace it caused a major transportation crisis in the region. However, no amount of resources could have saved this bridge.

When such situations occur, the operation to remove the product from the now open, burned-away compartments is extremely difficult and hazardous. That is the main reason major tanker trailer fire incidents in an open location without exposures should be allowed to burn. Also, be aware that if such an incident is allowed to burn itself out, the public and the press will want to know why. Know your strategy and tactics, be confident in your knowledge and experience, and be prepared to provide valid reasons, and you will be successful in your decision making and the mitigation of these tanker trailer-related incidents.

LEIGH T. HOLLINS retired as a battalion chief with Cedar Hammock (FL) Fire Rescue after serving 30 years with the department. He joined the fire service with the Nottingham Fire Company in Hamilton Square, New Jersey, in 1976. Hollins is an editorial advisory board member for Fire Engineering and FDIC International and has been a lead instructor for Hands-On Training at FDIC since 1996.