Jerry Knapp

The following scenario will demonstrate how important it is to include gas industry best practices (strategies and tactics) into your standard operating procedures (SOPs) and department training plan.

Scenario

Your company is dispatched to an odor of natural gas in front of 3 Main Street at 1023 hours. Leaving the kitchen table, the engine crew grumbles about another annoying gas leak call. When you arrive on scene, there is nothing unusual, but the homeowner meets you and says she had been smelling gas near the curb in the suburban residential neighborhood for the past three hours.

Your probie dismounts the engine with you and reports that the four-gas air monitor is warmed up and ready. You and your crew search, looking for the source and trying to pinpoint the leak for approximately 20 minutes before the utility’s gas technician arrives. You have evacuated the home nearest the odor site and are conferring with the gas technician about the next steps. Suddenly, the house across the street violently explodes. Instantly, this call becomes a life-or-death situation for all on scene. The blast threw you across the street.

The first thing you see as you regain your senses is your driver dragging the probie out from under the rubble of the fully destroyed home. The probie is limp and unconscious; you pray he is not dead. The street and surrounding yards are filled with debris that once constituted the house: small parts, big parts, joists, rafters, and large sections of roof and walls. You notice that the charred front door and frame made it across the street and are lying against your engine, which has a broken windshield and shrapnel damage. You were in the kill box without a plan B.

You thought you had identified the hazard. What you did not know was that the frost layer in the ground prevented the natural gas leaking from the underground gas main from escaping harmlessly into the air. Some of the gas did escape through cracks in the pavement and caused the odor the caller smelled. The remainder of the gas followed the path of least resistance and migrated into the nearby home until it reached the flammable range. When the thermostat called for heat, the boiler came on and all hell broke loose.

Discussion. In this scenario, the first-due company officer was trying to figure out the strategy and tactics for this type of natural gas emergency. Consider your department’s gas emergency response procedures. Does your SOP contain only some basic facts about gas and some do’s and don’ts? If this is the case, your SOP leaves it up to the first-due officer to develop the critical steps (procedure) to mitigate this emergency. In fact, if your SOP does not contain steps or appropriate procedure-based guidance for you to follow, it is not a procedure at all. “Procedure” describes a specific way to accomplish a task, a series of steps followed in a definite order. Many fire department SOPs on gas emergencies I have researched/reviewed are weak: They do not include a series of steps or are not based on an established protocol for accomplishing a task. And, they certainly don’t reflect best practices of the gas industry. Some of these SOPs are simply a collection of facts and leave the strategy development to the company officer on the first-due rig. It is assumed that a fire officer “just knows” the hazards of natural gas, migration patterns/routes, evacuation priorities, how to interpret meter readings, how to use subsurface structures, and the steps to take to mitigate the hazard. Imagine if we allowed our paramedics to treat injured victims this way!

Contrast this lack of procedures with the policy and procedures of the gas utility company. Its gas technicians spend weeks training and practicing procedures for responding to gas emergencies. They use gas industry best practices and procedures to ensure their actions provide the best possible outcomes.

(1) Debris covers a wide area of the kill box. (Photos by author.)

Utility Procedures

If the utility in your area is cooperative, it will share procedures with you and may even allow fire department members to train with its gas technicians, the people you will work with at gas emergencies. In addition to this joint training, a common radio frequency will enhance your effectiveness on a joint response with the gas technician. This common radio frequency is a force multiplier: Its cost is low, and it increases safety and efficiency. Keep in mind also that you will have two subject matter experts on the scene, the gas technician and the fire officer. The fire officer is the life safety expert and may be the responder who is held accountable.

If your utility is not cooperative, gas company response procedures are considered public documents and can be easily obtained through the Freedom of Information Act. It takes some effort, but read, digest, understand the procedures, and modify your SOPs and training to mimic them to improve your response procedures. Your state utility regulating agency is there to help you and protect the public; partner with it to the fullest to maximize your safety. Often, its only perspective on fire department-utility interaction/training/cooperation is what the utility tells it and may not reflect reality.

The additional information provided in the utility’s procedures and best practices provides you with background information that is important for your safety, such as how a frost layer traps gas underground. As at a fire, an effective size-up and an understanding of the dynamics of the hazard will determine if the response succeeds or fails. This information and other facts will be strategically and tactically important to you on the scene.

(2) A simulated reduced-scale multifamily home on Leak Street.

Training

A successful five-phase fire department gas emergency training program is taught at the Rockland County Fire Training Center in Pomona, New York. The first four phases include critical background information, technical tasks such as monitoring air, interpreting readings, procedures, and tactical application of procedures. They were covered in previous articles.1 The fifth and most important phase, the full-scale, hands-on capstone portion, is described below.

(3) The right side of Leak Street houses 2, 4, and 6. Note the hydrant, light pole, and simulated but realistic sanitary sewer. .

Phase 5: Tactical Application: Leak Street

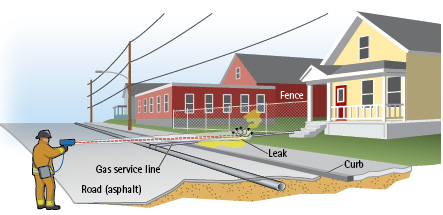

We cannot expect our officers and members to execute in the street what they have not practiced in training. Phase 5 is conducted on a training aid called “Leak Street.” Located on a previously unused road at our training center, Leak Street provides a realistic venue for scenario-based response to gas emergencies. It represents a suburban residential neighborhood. Six prefabricated sheds represent homes. The paved street contains curbs, sidewalks, hydrants, street lights, and storm drains. There are simulated sanitary manholes (just the upper ring and cover) where trainees monitor the air for gas migration into sub-surface structures and nearby buildings. All sheds mimic houses in a residential neighborhood and have a real gas meter on the side or in the rear. Leak Street is the result of my research driven by post-traumatic growth after my captain and I were nearly killed when a house exploded at an underground gas emergency. Leak Street provides a practice site for the following critical tasks for a safe and effective response:

• Practicing procedures for specific types of leaks.

• Life safety—civilians and firefighters are always the priority.

• Incident command and command post operations.

• Safe parking of apparatus.

• Identifying and staying out of the kill box.

• Air-monitoring meter use and interpretation of data.

• Action levels for meter readings and mandatory actions such as evacuation.

• Shutting off the gas meter under live fire conditions.

• Protecting exposures with a handline.

• Improvised explosive building (locked containing gas) procedures.

• Monitoring of subsurface structures to help track migrating gas.

(4) Firefighters prepare to use a fog stream to control the fire and shut off the valve to extinguish the fire.

Leak Street provides multiple and variable gas emergency scenarios common to our supported fire departments. Local departments can use and test their existing procedures as in-service training or use the model procedures supplied during the didactic, tabletop, hands-on, and discussion parts of the training.

Components of Leak Street

Left side: Building #1 is a multifamily home with three meters and contains a real (though not supplied with gas) boiler, hot water heater, hot-air furnace, stove, and clothes dryer hooked up with various types of gas piping, which includes black threaded pipe, corrugated stainless-steel tubing, and some creative piping that we discovered at actual alarms. These props serve two purposes: to familiarize firefighters with legal and illegal installation of gas piping, valves, and appliances and to provide a venue to train firefighters whose SOPs direct them to find the leak at the source. Although there is no real gas in any of the buildings, firefighters can go through the steps described in their SOPs. The three meters on this simulated multifamily home force fire officers to analyze the threat presented so they can determine which meters to shut off at multifamily buildings.

The next building, on the same side of the street, is #3. This home has a meter on the far side and a car in the meter vicinity. The meter is piped with compressed air from an air cart that has two one-hour air bottles. The leaking air provides the hissing sound of a leak. This simulated source of “gas” was selected for safety and cost effectiveness. There is no need for an on-site air compressor or electric service. The air bottles are filled off the same compressor used for self-contained breathing apparatus.

The third house, on the left side end of Leak Street, simulates a locked building containing gas or an occupied home that may need to be evacuated in support of other scenarios.

Right side: It contains three homes. #2 has a gas meter and is a venue for monitoring air and evacuation if the scenario requires it.

#4, the middle red building, has another common scenario our departments face: third-party damage to the gas service line or gas main by a contractor or homeowner. Air, piped by compressed air from an air cart, flows through the meter and into an exposed pipe that was damaged by the homeowner when he dug a hole to plant a tree in his yard. This scenario is based on an actual response where a plastic main was in the yard of a residence, instead of in the street, where we expected to find it. We learned that gas mains and valves can be located anywhere in a neighborhood (front/back yards) and may be only 18 inches deep. If landscaping is modified after the original installation, gas mains may be surprisingly close to the surface and susceptible to damage. Another training lesson incorporated here is that if third-party damage has occurred to piping outside, firefighters need to check the inside piping for damage and leaking gas.

The last house contains large doors on the far side to allow easy movement of our live fire prop, a simulated gas meter powered by propane used to allow firefighters to use a fog stream as protection while turning off a burning meter at the valve. Live fire helps make the training real. The prop can be placed near the sheds so that a handline is needed to protect the exposure, another realistic scenario touch.

Each of the houses can function as a supporting prop for individual scenarios and provide flexibility to scenarios that necessitate different command decision-making, air-monitoring, and evacuation considerations.

In addition to providing a training venue for the six most common gas emergencies, Leak Street can be used for training for two scenarios that necessitate special attention: the outside odor of gas and the improvised explosive building or locked building. As previously noted, an underground leak can turn deadly in an instant, and responding firefighters need to use gas industry best practices to limit the danger to civilians and firefighters. We all tend to get complacent after we have been to numerous outside gas odor complaints when nothing bad happens. If you don’t have a procedure based on best practices, finding and determining the limits of an underground migrating gas leak are like chasing the invisible man who is playing hide and seek with you.

Leak Street allows a nearly full-scale opportunity for departments to practice procedures that are systematic, working (air-monitoring and evacuation) from the leak site (most dangerous) outward to identify gas migration and migration pathways (storm, sanitary, pipe chases, and through the ground). Trainees can enter buildings near and remote from the leak and check (air-monitor) storm and sanitary systems for possible migration routes into buildings through subsurface structures.

Meter readings are supplied by the Bullex 4 gas training system. This system also has remote transmitters that send readings to the trainee unit during the scenarios. These transmitters are placed in Leak Street homes and in the fake sanitary sewers; trainees approach and get actual elevated levels on the meters.

Locked Building

Locked buildings that contain gas or potentially explosive concentrations of gas are also a significant hazard to firefighters. Some utilities ask fire departments to force open the door to gain entry for gas technicians. This is an extremely dangerous option and should be considered carefully, especially if there is no confirmation of a life hazard inside. This is one of the scenarios available on the Leak Street training prop. Firefighters want to immediately fix any hazard, as we do at working fires. Leak Street teaches firefighters to practice air-monitoring from the outside; relay that information to the incident commander; back away and get out of the kill box; have the utility shut down gas and electric service; and let the building vent naturally. This option is in many gas company procedures. Most gas company procedures recommend this option when any level of gas is detected from the outside of a locked building.

(5) An instructor shadowing the trainee can send simulated gas readings to the trainee based on the scenario.

There is no safe way to force entry into a building that contains flammable gas. Taking a window may be the best option since it causes no sparks and can be done with risk to only one firefighter. If the building explodes while taking the window, there is no plan B. Our turnouts are not rated for explosions. If things go bad, it will be the grace of God or luck that will determine if you survive. It is a very high-risk operation and should be undertaken only when necessary. Urban fire departments do this routinely on apartments when there is a high risk to nearby occupants. In a suburban or rural setting, patience may be the best strategy.

Funding

A number of funding sources are available to build, maintain, and operate your own version of Leak Street. The Pipeline and Hazardous Materials Administration has an excellent grant program and is very supportive. Another source is your state utility-regulating agency. Local utilities are fined for safety violations and other procedural errors. These fines are often turned into “negotiated settlements” and can be a source of funding to support training for first responders. That is how Rockland County’s Leak Street was funded.

In the case of the East Harlem, New York, gas blast that killed eight people in 2014, Reuters reported that Con Edison reached a state record settlement of $153.3 million in 2017. According to Reuters, “It followed a June 2015 report in which the National Transportation Safety Board said the explosion was likely caused by a faulty connection between two Con Edison gas pipes, as well as a hole in a nearby sewer line that New York City had known about for at least eight years.” Part of this settlement will go for increased training and education.2

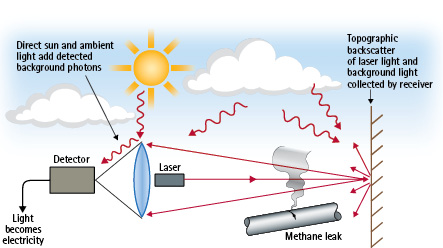

Figure 1. Remote Methane Leak Detector

A laser is projected onto a target, wall, grass, or other surface. Some of the beam is scattered by the gas it passes through. Returned light is focused on a detector that converts the signal to the methane readings that are displayed. (Illustrations used with permission of Heath Consultants Inc.)

The Georgia Pipeline Emergency Response Initiative

The value of FDIC International for networking and collaboration cannot be overstated. After my gas emergencies classroom presentation at FDIC International 2017, a representative from the Georgia State Fire Academy briefed me on the very successful Georgia Pipeline Emergency Response Initiative (GPERI) statewide program. According to the fact sheet, GPERI is a “public‐private partnership among emergency responders and Georgia pipeline operators to improve pipeline safety in the State of Georgia.” Its mission is to “advance the ability of Georgia emergency responders to manage pipeline emergencies through improved training, cooperation, and communication with pipeline operators.”

Figure 2. Conditions Needed for Detecting a Gas Leak

Three conditions are needed to detect a gas leak: A sufficient plume, the beam must pass through the plume, and there must be a background to reflect the beam.

Bearing in mind the weakness often found in our training and SOPs, the focus of GPERI is important. It focused initially on fire departments because they are typically the lead responders for fires, rescues, explosions, and hazardous materials emergencies. GPERI plans to develop training modules for other critical responders (law enforcement, emergency management, for example) commensurate with their role in pipeline emergencies.3

Currently, the GPERI program is managed by the Georgia Association of Fire Chiefs, expands on existing hazardous materials training, and provides the following training:

• Command Officers Strategies: A four‐hour training program for chief officers that emphasizes strategic awareness, planning, and unified command, using the National Incident Management System.

• Company Officer Tactics: Intended for officers and their crews, this eight‐hour module focuses on scene safety, initial incident command, incident assessment, notifications, and other tactical considerations.

• Dispatcher Awareness Training: A four‐hour course designed for 911 call takers and dispatchers to improve information gathering and notification skills specific to pipeline emergencies.

• Pipeline Emergencies: A comprehensive 16‐hour class for trainers and firefighters with a need to have a more in‐depth understanding of the pipeline emergencies curriculum.

Technology

New technology, such as thermal imaging cameras, has made our job safer and increased our fireground effectiveness. A very promising technology for gas emergencies is a remote methane leak detector (RMLD) (Figures 1-2). As the name implies, this man-portable device can detect natural gas leaks remotely using a focused laser and does not necessitate that you be in the hazard area. It can operate through glass and thus detect gas levels inside locked buildings.

For the fire service, this tool can act like a bloodhound and provide some important direction for the incident commander during size-up of a gas emergency. This technology has been used in the gas industry for the past 12 years and has proven successful for instantly identifying the location of escaping natural gas. Its use by first-in fire department members will greatly speed up size-up so that mitigating actions can be executed, saving civilian and firefighter lives. According to the manufacturer, Heath Consultants, the instrument measures 0-99,999 parts per million (ppm) of methane (lower explosive level = 50,000 ppm); can read 5 ppm at 50 feet; and has self-testing and calibration integrated into the case.

Responding to natural gas emergencies necessitates an authentic procedure, a series of steps, similar to the protocol paramedics use for medical emergencies. Our gas emergency response procedures and SOPs must be based on and aligned with gas industry best practices and with new technologies. To ensure success, efficiency, and safety on the emergency scene, we must provide realistic training opportunities for officers and firefighters.

Endnotes

1. See the series by Jerry Knapp and Daniel Moran: “Improving Response Procedures to Natural Gas Emergencies,” “Natural Gas Emergency Strategy and Tactics,” and “Training for Natural Gas Emergencies,” Fire Engineering, March, April, and May, 2017, respectively.

Jerry Knapp is a 40-year veteran firefighter/EMT with the West Haverstraw (NY) Fire Department and a training officer at the Rockland County Fire Training Center in Pomona, New York. He has a degree in fire protection and is the chief of the Rockland County Hazmat Team and a battalion chief and a member of the Rockland County Hazmat Task Force. He is the author of the Fire Attack chapter in Fire Engineering’s Handbook for Firefighter I and II and of numerous articles for Fire Engineering. He is on the technical panel for the latest UL study on fire attack at house fires and recently retired from the U.S. Military Academy, West Point, as the plans officer, Directorate of Emergency Services.

RELATED

Natural Gas Emergency Strategy and Tactics

Training for Natural Gas Emergencies

Improving Response Procedures to Natural Gas Emergencies