By Mark Rossi

On January 18, 2017, at 7:53 a.m., Fort Lauderdale (FL) Fire Department (FLFD) units responded to a large warehouse fire with unknown chemicals involved in the “Uptown Business District” of the city. On arrival, initial responding units were met with a well-involved 300- × 100-foot, 30,000-square-foot warehouse with heavy fire showing through the roof. The one-story building was of type II (noncombustible) construction, consisting of concrete block walls and a metal deck roof supported by lightweight, unprotected steel bar joists (parallel chord trusses). The fire building was H-shaped; a courtyard and loading docks were on three sides of the structure. Visability and access to the structure were limited, as the structure bordered a canal in an industrial park in an unincorporated part of the city that had few hydrants and access roads.

Initial Actions and Strategy

First-arriving companies found the main body of fire in the A and B sides of the structure, involving 90 percent of the south wing of the building. Access to the B side was hampered by debris in the roadway, the result of an explosion that occurred prior to the arrival of the first engine company, Engine 88, which transmitted a request for a second alarm and initatiated an offensive attack on the A/D corner through the loading dock with a 2½-inch hoseline. The crew of Rescue 53 (stationed with Engine 88) arrived and assisted with the initial attack line. An additional 2½-inch hoseline was placed in action with the arrival of a neighboring engine company—the involved building sits on the border of two cities. Within minutes, Engine 88’s officer realized conditions in the structure were deteriorating quickly and advised command that defensive tactics were in order. Battalion 8 was in command and decided to go into a defensive operation. Engine 88 withdrew from the structure and began setting up ground monitors as several of the first-alarm units began arriving. Two ladder trucks arrived and began setting up for elevated master stream operations on the A/B corner of the structure (Pompano Beach Ladder 52) and the C/D corner of the structure (FLFD Tower Ladder 2). Multiple five-inch water supply lines were laid to the engine and ladder companies operating on scene. Because the hydrants in this area are 500 feet apart, two relay operations were set up to supply the aerial apparatus.

(1) Heavy fire on arrival. (Photos by author.)

Hazardous Chemicals Found

Once the fire was under control, since we did not initially know the nature of the chemicals inside the structure, FLFD’s Hazmat Team (Engine 88) and Hazmat 17 from Broward Sheriff Office Fire/Rescue assisted in determining the chemicals involved in the fire. The incident commander assigned a Hazmat Group. When the Hazmat Group eventually met with the owner of the business, they learned that at the time of the fire the following chemicals were inside the fire structure:

- oxalic acid, 100 gallons

- sulfuric acid, 100 gallons

- phosphoric acid, 100 gallons

- acetic acid, 100 gallons

- sodium hydroxide, 100 gallons

- nitrate salts, 5,000 pounds.

Because of the extensive damage from the fire, the chemicals could not be assessed or contained. Engine 88 returned to the scene every few hours to extinguish hot spots and assess the scene for further hazards. This was done until shift change the following morning.

Water Supply Issues

About 20 minutes into this working fire, we realized that we did not have the volume of water (or residual pressure) to support the multiple aerials and ground monitors placed in service because all of the initial arriving units were on the same looped hydrant water system. In addition, there were multiple long five-inch supply lines from hydrants down the street supplying the units on scene.

Once second-alarm units began arriving, relay operations were established with a supply engine at the hydrant, a relay engine in the middle of the layout, and the attack engine on scene. Once this operation was in place, the attack engines had adequate pressure to pump their lines. Clearly, boosting pressure in supply lines by connecting engines directly to hydrants cannot “make” water, but it was the most effective means of taking advantage of a hydrant’s available water.

Units working on the scene suggested to command that they draft from a large canal bordering the south side of the property to obtain the water to supply the ground monitors and ladder trucks. Crews worked to pull an initial draft from the canal and supply the engine on the B side (Engine 35).

Once Engine 35 had its ground monitors in place and actively flowing, it was also able to supply the ladder truck positioned on the A/B corner of the structure through approximately 500 feet of five-inch supply hose. Realizing the drafting option was working well and allowing engineers to dump thousands of gallons of water on the fire, command requested a second draft from the crew of Engine 29. Both were successful operations, but it took some thinking “outside the box” to get them in operation.

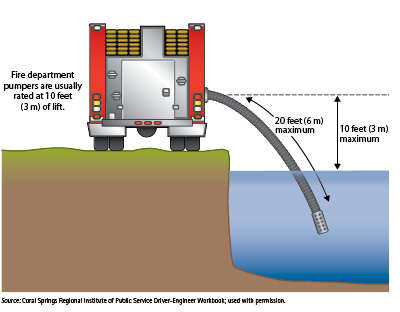

Figure 1. Pumper Lift Rating

Drafting at this fire was far from a textbook operation. Ideally, driver-engineers should spot the apparatus on solid, level ground as close to the water’s edge as possible. Correct drafting procedures typically call for two 10-foot sections of hard suction hose to be coupled together, with the strainer at least two feet below the water’s surface and one foot off the bottom at all times. Additionally, the fire service hydraulics and pump operations texts recommend lift—that is, the distance between the water’s surface and the intake of a pump should be limited to a maximum of 10 feet. Accordingly, most fire department pumpers are usually rated at 10 feet (or three meters) of lift.

Conditions at the drafting site, however, were less than ideal, which forced the engine companies to violate some of the basic guidelines of drafting. First, there was a metal guardrail that prevented the driver-engineer of Engine 35 from spotting the apparatus closer than 25 feet from the canal. This necessitated the coupling of three 10-foot sections of hard suction hose. Even with the additional section, the strainer was submerged just below the surface of the water. With the suction hose on the ground, it was nearly impossible to pull a draft. To obtain some manageable lift, crews ended up maneuvering three ground ladders under the hard suction (photo 2). At first, all on scene were skeptical about this working. After several minutes of priming the pump and troubleshooting, we were able to successfully pull a draft from the canal.

Immediately following the success of this drafting operation, command assigned crews to assist Engine 29 to do the same. Its drafting operation was much more ideal—the apparatus was placed closer to the water’s edge, allowing for a better lift and positioning of the hard suction hose.

Preplanning Water Resources

In Fort Lauderdale, most hydrants are within 300 to 500 feet of each other and supply enough pressure and gallons per minute (gpm) to successfully extinguish most of our fires, including the large commercial ones. As a result, it is rare for engine companies to have to perform drafting operations. Water supply is a primary consideration of the engine company officer’s size-up. It is best to identify hydrant locations, water main sizes, and locations of dead-end mains and drafting sites during prefire planning and document them for quick reference in a binder or an apparatus mobile computer.

Water Supply Tactics

Obtaining a secure water supply starts and ends with discipline. Department standard operating procedures (SOPs) should clearly delineate responsibility for securing a water supply. For example, if SOPs permit the first-arriving engine company to respond directly to a fire scene and begin attacking a fire with water from its booster tank, then it must be the responsibility of subsequently arriving engine companies to establish an adequate and sustained water source. This assignment is just as crucial and important as putting the fire out successfully.

(2) Engine 35 works to obtain a draft through 30 feet of hard suction hose and three ground ladders to achieve the desired lift.

Without water, fire doubles in size every 30 seconds. Although not as glorious as actually putting out the fire, securing a water supply saves lives and property, which is in every firefighter’s job description. When water supply is neglected, it can result in greater property loss and increased dangers to firefighters.

Adequate water supply during fire attack operations has a critical impact on controlling the fire. A good water supply results in favorable outcomes. Delayed or limited water supply leads to delayed fire control, increased risk to firefighters and victims, and greater fire loss. Engine companies must train to proficiently perform water supply evolutions, such as forward (hydrant-to-fire) and reverse (fire-to-hydrant) hoselays. Additionally, they must train in operations that are performed infrequently, such as drafting from static water sources, relay pumping for long hoselays, and tandem pumping to achieve the high pressures necessary to supply fire department connections at extremely tall high-rise buildings.

Water supply begins with dispatch information. Where is the call? What type of structure? Is this a commercial or residential structure? Is the building in question single story or multiple stories? How is the access to the scene? What hazards will you encounter? Resources are a critical consideration of water supply, especially for departments that permit the first-arriving engine company to respond directly to the scene and begin an initial attack with tank water. Don’t rely on the second-due engine to lay a supply line if it is responding from several miles away.

The water issues the FLFD faced in this fire were not those we face on our “bread-and-butter” commercial fires. Typically, we have enough hydrants in our city to supply the needed volume. Because the fire was in an unincorporated part of the city, the need for additional pumps was not recognized. Typically, when you anticipate a high demand for water, notify the water department as soon as you recognize the problem. The water utilities can put additional pumps in line to increase pressure in the water system.

Ultimately, every engine company is responsible for its water supply. If the delay of the second-due engine’s arrival is excessive, then the first-arriving engine should seriously consider establishing its own sustained water supply. Although most of the time the officer makes the ultimate decision on whether to perform a straight/forward lay vs. a reverse lay, input from an experienced driver-engineer will make this decision easier for the officer. Some departments require the first-due engine to lay its own supply line.

In the FLFD, the first-arriving engine is permitted to perform a fast attack on a fire with tank water. It is the responsibility of the second-due engine to lay a supply hoseline to the first-due engine for a residential fire and the third-due engine on a high-rise fire. Many of our experienced driver-engineers secure their own water once the initial line is put in place on residential fires.

I like to reverse lay a supply line from the fire scene to a hydrant if my company is tasked with water supply. This leaves room for the first-arriving truck company, which should be directly in front of most structures, and moves our engine out of the way for other incoming units. Additionally, pumping supply hoselines from an engine connected directly to a hydrant takes maximum advantage of its available water. Remember that a fire hydrant is designed to flow its maximum capacity from every outlet. Gated valves connected on unused outlets will allow later connection of additional suction hoselines to pump intakes without interrupting the flow of water. Think about which decision you might make well before your arrival on scene regardless of the incident.

Do not attempt to discharge more water than your pump is receiving from its water supply. To prevent cavitation, maintain at least a 20-psi residual pressure reading on the pump’s master intake gauge. Knowledge of your apparatus attack lines and master streams is the key to knowing how much your apparatus is flowing in gpm. A basic understanding of hydraulics, experience, and knowledge of modern fire dynamics is necessary to determine how much water is needed to absorb sufficient heat energy from a fire to achieve rapid extinguishment. Without resorting to complex formulas, think “big fire, big water.” Know the capabilities and limitations of your handlines.

The fire load and compartmentation of residential buildings often limit the volume of fire to within the suppression capabilities of 1¾-inch hose. Fires in commercial buildings call for larger attack lines such as 2½-inch hose flowing at least 250 gpm or master streams flowing at least 400 gpm. Once you have an idea of how much water you need, you can determine how to secure an adequate water supply and devise tactics to effectively apply streams to the fire.

(3) Engine 29 sets up a successful draft operation within minutes.

Lessons Learned from Our Drafting Operation

Know your pump’s capabilities. Although drafting operations are not the mainstay of the FLFD, if we do not have an idea of our pumper’s capabilities and what we can do to increase flow, we may waste a lot of time and energy moving less water than we can without minimum resources. We must be constantly thinking outside the box when it comes to many fireground tasks, especially water supply for large fires.

Know what drafting is, when you need it, and how to draft. Drafting is one of the most neglected training topics in a firehouse because it is not too popular. Most driver-engineers want to know how to get a prime and move water from a draft, but they aren’t interested in understanding drafting, how to maximize flow, or gaining gpm from a drafting operation.

In the FLFD, I would guess half of the driver-engineers know this skill well enough to make it work when it is needed. The rest probably don’t even think about it because of our supply of hydrants in the city. Sooner or later, almost all firefighters will face the need to pull water from something other than a standard “wet” hydrant. Even if most or all of your district is equipped with standard hydrants, the potential always exists for the water supply system to malfunction or to fail to provide a supply that matches the required fire flow for the given incident. In these cases, drafting may provide the only alternative to getting the water you need for the firefight.

Troubleshooting the drafting operation. One of the major challenges we had with our drafting operation was getting close enough to the drafting site on the canal bank. Remember that mobile centrifugal fire pumps are designed to draft at 10 feet of lift maximum. Although these pumps may be able to produce a flow greater than this, you may also achieve a flow that’s less than the pump’s rated capacity. We had to use ground ladders to troubleshoot the lift and get the flow we wanted.

That said, draft can be pulled at greater than 10 horizontal feet from the source if the total vertical lift is approximately 10 feet or less. If enough hard suction (or piping for a dry hydrant arrangement) is available, you can position pumping apparatus 60 feet or more away from the water source, but all the hose connections must be extremely tight to avoid air leaks that can limit or prevent a successful draft; hand-tightening the connections is usually not enough to avoid this. To properly tighten connections, apparatus that need to draft should carry a rubber mallet, which we use to make our connections.

Water supply is one of the most fundamental and basic operations on the fireground, and its importance cannot be underestimated. A good water supply operation demands diligent training, constant preplanning, use of available resources, and a working knowledge of hydraulics.

It’s the job of every engine company to anticipate long-term fireground water-supply needs as they arrive on scene. Failing to recognize a working incident can cause an engine company to miss an opportunity to secure a water supply that may be key to controlling an incident. This can be even more critical when operating at an extended scene at a large commercial structure, high-profile types of calls, and residential fires with limited access where only a single pumper can enter.

Remember: Be proactive, not reactive. Expect the unexpected when it comes to securing a water supply. Following these guidelines will ensure your crew’s safety, and the result will be an operation that continuously delivers an adequate amount of water to the fireground in a safe and effective manner.

Bibliography

International Association of Fire Chiefs. Fire apparatus driver/operator. Place of publication not identified: Jones & Bartlett Learning, 2015. Print.

Jacobus, Greg. “Drafting Tools & Techniques.” Fire Rescue Magazine. 1 Mar. 2012. Web. 10 Mar. 2017.

Spurgeon, Paul. “Drafting.” Fire Service Hydraulics & Pump Operations: Instructor Curriculum. Place of Publication Not Identified: Pennwell, 2013. 93-94. Print.

Mark Rossi is a captain with the Fort Lauderdale (FL) Fire Department, where he has served for the past 12 years. He is assigned to Battalion 2 in the downtown district. He was previously assigned to the Training and Special Operations Division and, prior to that, Engine Co. 46, where he spent almost eight years honing his craft as a driver-engineer. He is a fire instructor III and live fire training instructor for the Coral Springs Regional Institute of Public Safety, where he teaches driver/aerial engineering classes, live fire, survival, and engine company operations. He is also a lead instructor for the First Due Engineer H.O.T. class for the Fort Lauderdale Fire Expo. He has a bachelor’s degree in finance and a master’s degree in business from the University of Florida.