By Jerry Knapp and Daniel Moran

This is the final article in our series on natural gas emergencies. In the March issue, we discussed the critical, background knowledge you need to fully understand strategic and tactical considerations associated with response to natural gas emergencies. In the April issue, we covered many of the important strategic and tactical considerations necessary to safely mitigate common natural gas emergency scenarios. Here we will focus on training your officers and members to use a procedure-based approach to natural gas emergencies, innovative training methods, and training aids to fine-tune your gas response skills and procedures.

“Miracle on the Hudson” pilot Captain “Sully” Sullenberger says about Captain Dave Cronin, who successfully landed a severely crippled 747 in 1989, and his crew: “The crew acted heroically because they knew, from their deep knowledge of the systems on that plane, that they would have to improvise and modify procedures in order to deal with this unexpected emergency. They acted bravely in getting the plane safely to the ground. As I studied the accident, I filed away the fact that I might one day have to rely on my systems knowledge, not only on a checklist. There isn’t a checklist for everything.”1

So, too, do officers and firefighters need a deep knowledge of natural gas emergencies, and we hope you file away some of this knowledge so you can modify your existing procedures to ensure the safety of your customers and crews when that routine gas emergency instantly escalates.

Training

We conducted an informal review (through local and national contacts) of currently available training on natural gas emergencies for firefighters. What we found was shocking! The gap in understanding and applying gas industry best practices and procedures is huge. Equally disturbing is the lack of effective training opportunities and methods, especially of joint scenario-based training with utility personnel. In general, it appears that each fire department essentially does its own training, which often is incomplete at best, supplemented by minimal training by the utility. The net result of this gap in training is that department officers of all ranks are often left without formal, proactive procedures.

Interestingly, even the definition of “training required” (by the utility for fire departments) is up for official debate. Check your state’s “required training” definition. In New York State, the applicable rule for training is PSC Rule 255.615(c). The wording is very general and does not specify the level of training. The key parts of this very short rule state the following:

(c) “Each operator (utility) shall establish and maintain liaison with appropriate fire, police, and other public officials to

- plan how the operator and officials can engage in mutual assistance to minimize hazards to life or property; and

- offer annual training, at mutually acceptable locations, to volunteer fire departments regarding the appropriate response to gas related emergencies and to police departments regarding the recognition of gas related emergencies. For non-volunteer fire departments, annually offer to assist the training coordinator in developing training programs for gas safety related matters.”2

Key words in the above rule are “mutual assistance” and “appropriate response to gas-related emergencies.” When the fire department and gas company technicians are on the scene, it is the classic mutual-aid scene at an emergency. Any reasonable person would conclude that joint, hands-on training is necessary to ensure a coordinated response that will promote the safety of our members; civilians; and, of course, the gas company personnel.

The classic “train the way you fight” is very appropriate here at the command and company levels. Consider that your fire department members and officers and the utility company’s gas technicians and supervisors will be working together at a potentially explosive situation. Joint training is a force multiplier and will produce a much more effective, coordinated, and safer response than two teams working separately.

Appropriate response to any emergency is a team effort supported by team training. Some utilities take the “Cheap Charlie” approach and provide only minimal classroom training. Others do a much better job. One utility-sponsored training session spent valuable training time discussing how gas was produced millions of years ago as a result of dead and decaying dinosaurs. Such information would be worthless at your next gas leak.

Phased Training

We developed out of necessity a four-phased interactive training plan at the Rockland County (NY) Fire Training Center for fire officers and firefighters. This program provides proactive guidance for effectively responding to natural gas emergencies. Each of the four phases is about a two-hour block of instruction. The goal is to fill the gap between huge shortfalls in what the utility provides and what is needed to prepare officers and members for the various types of gas emergencies we have previously discussed.

Much of the training is based around gas industry best practices and response procedures we obtained by electronic Freedom of Information Act requests through the New York State Department of Public Service. Gas industry response procedures are public documents. They are not proprietary, classified, or protected for homeland security issues. We used these procedures to provide a model fire department standard operating procedure (SOP) that could be adjusted for each department’s local conditions and specific policies.

Firefighters are generally not fond of classroom training. However, when you start the class by telling them you are going to “blow something up,” it gets their undivided attention. More importantly, it provides training they will not forget.

Phase 1

The objectives are to provide tactical awareness, foster an understanding of natural gas hazards, highlight safety precautions, and discuss policy and procedures. Case histories in the forms of video and reviews of natural gas emergencies where firefighters were killed or injured are used to illustrate the unpredictability of a natural gas emergency and the need for solid response procedures. The students then gather around the explosion chamber to witness the unpredictability of natural gas leak scenarios.

Students are made aware of the safety limitations of turnout gear in explosions and in shielding firefighters from the hazards of explosively propelled glass fragments, large parts of the building, other debris, and burns. The concept of the kill box is introduced and compared to the collapse zone.

Life safety first – the mission of the fire department at natural gas emergencies – sets the tone for the remainder of the class, which emphasizes that firefighters should anticipate the worst-case scenario at a natural gas incident until the facts prove that it is safe to downgrade the incident.The types of leaks and the need for fire department leaders to establish policies and procedures for members to follow at these emergencies are also discussed.

The gap between fire department SOPs and gas industry best practices is explained, as is how to obtain your gas company’s response procedures through the Freedom of Information Act. Class discussion centers around questions such as the following: Are you using gas industry best practices? If all you get is some weak lecture by the gas company, is this awareness level training enough for you to operate at the technician or command level at real emergencies? How much air-monitoring training have you had? Does your department have joint training with gas company responders and management or good procedure-based SOPs that go beyond a list of do’s and don’ts?

Phase 2

This section of the training covers the following:

Air-monitoring procedures, understanding your department’s four-gas monitor, and interpreting the data the monitor gives are the focus. Many fire departments have air-monitoring instruments, but we found that many members need to strengthen their skills in using the devices and understanding and interpreting the readings. Included is a short lecture on flammable range for natural gas, use of the meter for air-monitoring, and the limitations of the instrument. Action levels are introduced and defined as follows: a meter reading that by department policy requires a mandatory action, usually evacuation of civilians and firefighters.

Explosion chamber. Students are given the opportunity to have their meter, which they bring to class, go into alarm mode in the explosion chamber. When a small amount of gas is introduced to the meter, the trainee calls out his meter readings. Discussions on low and high alarms, lower explosive level (LEL) readings, the decrease in oxygen reading, and the reason the carbon monoxide sensor is in alarm follow. The training is interactive. After some research and trial and error, we built our own explosion chamber. We built it with parts found in the basement. We have partnered with our local Board of Cooperative Educational Services to build a more professional looking version.

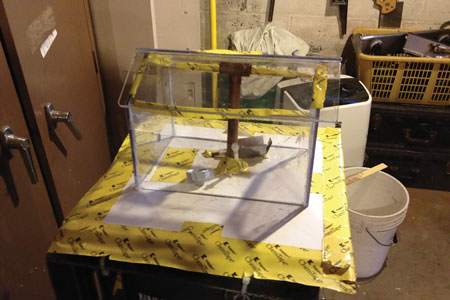

The home-made explosion chamber is constructed out of a milk crate turned upside down, a thin piece of plywood, and a plexiglass cylinder. A piezoelectric barbecue igniter provides the spark for propane gas from a small torch cylinder piped into the house with ½-inch copper pipe (photo 1). This device was borne to prove the concept and has served well ever since.

|

| (1) The prototype explosion chamber with a gas meter attached through tubing. (Photos by Jerry Knapp.) |

The explosion chamber provides the following demonstrations:

- Unpredictability of natural gas emergencies. The instructor introduces a small amount of gas into the chamber (without a meter inside). However, the chamber does not always ignite when the trainee pushes the igniter. When the gas does ignite and the fire ball drives the foil top above the trainees’ heads, it enforces the message of unpredictability.

- Effect of varying amounts of gas within the flammable range. The evolution is repeated several times – once with just enough gas to get it to ignite, producing a weak launching of the foil plate. Then an amount of gas in the middle of the explosive range is used, producing a more powerful ignition and a high flight for the plate. Since we have seen increasing intensity by using larger amounts of gas for each succeeding evolution, invariably a trainee will encourage us to use “a lot of gas.” We can predict that the mixture will be too rich; it again produces a weak ignition. We may know the facts, but when the trainees see it and have time to consider it and tie it to the unpredictability of a natural gas emergency, it makes important and critical points. This evolution also reinforces the need to monitor the level of gas with instruments.

- One of the trainees’ meters is placed in the chamber, and a small amount of propane is released, sending the meter into alarm. This is often the first time many students have seen their meter alarm. We discuss low and high alarms (10 percent and 20 percent LEL, respectively) and link them to the action levels that should be in their SOPs. Although there is not a nationally prescribed number, we recommend immediate evacuation of both civilians and firefighters at 10 percent of the LEL. This is not to say your action level cannot be lower: 10 percent of the LEL or 0.5 percent of gas in air) should require mandatory and immediate evacuation. The point is, senior leaders must have an established action level in their SOP, and subordinates must know the proper reaction. Trainees get to see, feel, and hear their meter in different alarm modes. It is important to note that the meter should not be saturated with gas. Small amounts of gas with a short duration exposure are enough to trigger the alarms for demonstration purposes.

- Readings above 100 percent of the LEL. There are several meter-specific and confusing displays when a gas concentration above 100 percent of the LEL is detected. Some of them include the following: OFF for off scale; OS for off scale; 999 for “I can’t read that high”; and, our favorite, “***,” which tells the user nothing unless he has read the directions for his meter. Only a few of the firefighters we trained knew their meter’s message when the reading was at or over 100 percent LEL. Another fact we drive home is that some meters stop sensing when they hit 100 percent LEL and must be purged and restarted to resume sensing.

- Cross sensitivity of sensors. Electro-chemical carbon monoxide (CO) sensors are cross sensitive to propane and methane. With the meter in the chamber and a small amount of gas introduced, the meter will read increased CO levels and often alarm for this substance as well. A discussion on cross-sensitivity, calibration gas, and correction factors follows.

- Oxygen levels. As flammable gas is introduced into the chamber, the meter will show falling (displaced) oxygen levels. This is the time we remind the students to read oxygen levels before LEL readings. Reduced oxygen can produce falsely reduced LEL readings, for obvious reasons.

Phase 3

With the background information fresh in their minds, the students move on to examining model procedures for each type of gas leak. Using a computer-generated overhead view of a simple residential street with five homes on each side, students and instructor “walk” through recommended practices for various leak scenarios.

|

| (2) A plexiglass house model with the roof not secured. The roof rises a few inches when the gas ignites. |

Trainees are advised of the gas technician’s responsibilities when he arrives on scene and a discussion of how to create a team effort between the fire department and the gas technician. During the segment, students often relate to the class their experiences of not being able to find the gas technician, situations when the gas technician was less than effective or cooperative, and other real-life situations the trainees thought were hazardous. Invariably, trainees mention that the gas company representative cannot always find and shut off valves to mitigate highly dangerous situations or after buildings have exploded.

Trainees are given a handout that provides a model SOP for them to follow in the subsequent hands-on exercises. It is stressed that the trainees’ department leaders may have to revise or develop an SOP covering natural gas emergencies. Trainers cannot and should not set policy for a fire department. However, this new-found knowledge will enable officers to set policy and procedures and to determine what their members will and will not do in a natural gas emergency.

Phase 4

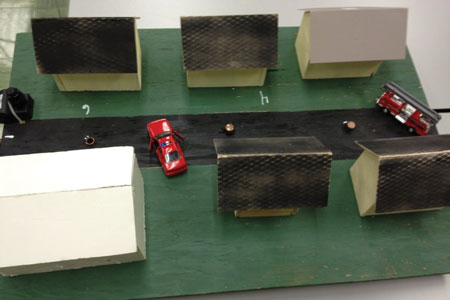

After the trainees have familiarized themselves with the suggested procedures handed out and reviewed in class, they are ready for practicing or walking through the procedures on a model town (photo 3), a residential street, Main Street, with houses 2, 4, and 6 on one side and houses 1, 3, and 5 on the other. Each house has a gas source and is vented at the rear to allow students to put in their meter and get a reading. Copper pipe with end caps in the street simulate sanitary sewer manholes and provide a gas reading when the students pull off the cap and place their meter near the open pipe.

|

| (3) A model town with one house removed to show the gas piping. |

An incident commander (IC), safety officer, meter crew, engine crew, and truck crew are selected from the group, ensuring maximum participation and a focus on the training. The model is piped to simulate three separate leak scenarios: (1) an odor in the street and gas in one home, (2) gas in two homes, and (3) gas in the sewer manholes and gas in the homes at each end of Main Street. Individual leak scenarios can be combined to add intensity and create more scenarios.

After the scenario is presented, the IC arrives on scene and places his small-scale vehicle and chooses a command post location in accordance with the SOP (photo 4). All students had been given a copy of the SOP for the scenario. The purpose here is not to stump the IC but rather to get all the trainees to follow along using the procedure. Often, we don’t allow the IC to direct the operation. He must ask the other trainees to provide recommendations. This helps ensure continued interaction from each of the trainees. There is a short discussion about preferred command post locations, why you should not drive through the scene, and other relevant considerations.

|

| (4) The IC and a ladder truck arrive on scene. Note the simulated manholes where trainees can take gas readings with their meters. |

The safety officer is given a long piece of mason twine and is asked to estimate the size of the kill box based on the information given. He places the twine around the appropriate homes. A short discussion follows.

It is also important to discuss the small scale of the model. Obviously, if houses in the trainees’ first-due areas are far apart, evacuating the nearby houses may not be necessary and designation of the kill box may be only around the house involved. The model town is used to give the trainees a mental picture to file away for use during real emergencies.

The truck and engine captains now follow the SOP and size up the scene, estimate the hazard, and determine what they know and what they don’t know at this point. They direct their meter crew to the appropriate locations [houses, sub-surface structures (SSS)]. Usually, gas leaking from the small holes in the model homes provides a reading and there is a discussion about action levels, evacuation, life safety first, and other related topics.

At this point, there are usually questions and an open discussion about what the utility technician is doing, what the hazard is, how big the kill box is, evacuations, and so on. Following the SOP and walking through the scenario have given them a simulation of what they would be doing in a real-world response. The discussions are interesting; most bring out several important learning points.

One of the favorite discussions is about stretching the classic precautionary handline. The instructor adds some fuel to that discussion by asking the following questions: Will a handline prevent an explosion? Will it protect your members if the building explodes? The point here is that this situation is not something we can control with a handline or a master stream. We must properly size up the hazards and limit the threat to firefighters (take manageable risks) while also being prepared to mitigate the situation if it goes bad.

Battalion Chief (Ret.) Frank Montagna, Fire Department of New York, stresses in his lectures: “I am a strong proponent of the precautionary line. It won’t stop an explosion, but that is not its purpose. Its purpose is to be ready for use after an ignition or explosion, not to extinguish the gas fire, but to protect surrounding exposures and to extinguish any nongas-fed resulting fires. Yes, you can sit on your butt and wait to stretch the line after it occurs; but it is better to position the pumper at a safe water source and stretch a precautionary line, even position a large-caliber stream to a safe but accessible position, so it is able to be rapidly repositioned if needed.”

|

| (5) A version of the model town in the hallway of the training center. |

Repetition here is the key and what phase 4 is all about. Trainees have been introduced to a model procedure, have practiced it on a model residential street, and now will practice it on a larger scale.

Since an underground leak is one of the most dangerous natural gas emergencies presented in this phase, trainees are given opportunities to practice on this scenario. The class further enforces the importance of detecting underground gas leaks. While waiting for our full-scale training aid to be built, we use simulated SSS made from recycled container tops on which a large-scale photo of a sewer manhole is adhered with two-sided tape. The hallway represents a road surface, and chairs on each side of the “street” are marked with house numbers. This simple mockup is combined with a state-of-the-art four-gas simulator.

We use a mockup of a four-gas meter that receives positive readings from an instructor transmitter and a remote transmitter. Used in combination with the simulated residential street, trainees can walk through their SOPs in a different venue. This repetitive practice reinforces a procedure-based response methodology. Here the tactic of monitoring SSS and removing manhole covers to provide a path of least resistance for trapped underground gas is reviewed and practiced. More importantly, trainees can remove the cover, reinforcing the training point. A lively discussion usually occurs at this point; many questions are answered. Trainees develop confidence in this procedure-based response methodology. An additional benefit of this evolution is that it builds the expertise of interpreting readings from the meter to determine the size of the kill box, the extent of the migration of gas, and evacuation needs.

Since the instructor can send simulated readings to the training meter in the students’ hands, critical concepts such as action levels, underground plume migration, and appropriate evacuation orders can be practiced. Again, this is in an informal setting; trainees are out of their seats in an interactive training session.

Our full-scale training venue is being built and will replace this hallway version. It will provide initial and in-service training for fire, police, and emergency medical services.

Natural gas emergencies often do not get the respect they deserve. We become complacent because we have been to so many leaks that were detected by people smelling the gas odorant at very low, nondangerous/flammable levels; consequently, gas leaks become another routine, annoying run. To do the best job possible for the people we are sworn to protect, fire service leaders and members must have a deep understanding of natural gas emergency response policy and procedures.

Endnotes

1. Sully, The Untold Story Behind the Miracle on the Hudson, page 188. Originally published as Highest Duty, Harper Collins, 2009.

2. New York State Department of Public Safety Web site: PSC Rule 255.615(c).

JERRY KNAPP is a 40-year firefighter/EMT with the West Haverstraw (NY) Fire Department and a training officer with the Rockland County Fire Training Center in Pomona, New York. He is chief of the hazmat team and a technical panel member for the Underwriters Laboratories research on interior and exterior fire attack at residential fires. He is the author of the Fire Attack chapter in Fire Engineering’s Handbook for Firefighter I and II and has written numerous articles for Fire Engineering.

DANIEL MORAN is a 45-year fire service veteran; a Rockland County (NY) deputy fire coordinator for hazardous materials; a member of the Rockland County Hazardous Materials Team; an instructor at the Rockland County Fire Training Center; and a former chief of the Suffern (NY) Fire Department. He has more than 40 years in the chemical-pharmaceutical industry as a research chemist. He has a bachelor’s degree in chemistry from Lebanon Valley College in Annville, Pennsylvania, and a master’s degree in chemistry from Fairleigh Dickinson University in Teaneck, New Jersey. He is an adjunct faculty member in the fire technology program of Rockland Community College (SUNY) in Suffern.

Improving Response Procedures to Natural Gas Emergencies

Natural Gas Emergency Strategy and Tactics

Natural Gas: Safe, Reliable, and Potentially Deadly

More Fire Engineering Issue Articles

Fire Engineering Archives