This article documents the benefits of using smooth bore nozzles on 2½-inch handlines. My experience has indicated that many students in the fire service have learned that the 2½-inch handline is not an attack line but rather a “leader or trunk” line used to stretch a 1¾-inch hose beyond its effective reach or to supply two 1¾-inch hoselines with a gated wye. The standard operating procedure (SOP) on how to load the line appeared to be the indoctrinating point: Caution: When considering friction loss in a 2½-inch trunk line supplying two 1¾-inch lines, each flowing 185 gallons per minute (gpm) from a 15⁄16-inch smooth bore tip, 370 gpm is produced. The resultant friction loss can be as much as 30 pounds per square inch (psi)/100 feet in extended stretch operations; pump discharge pressures may be excessive.

How often do firefighters drill on deploying the 2½-inch line in an offensive, aggressive posture as they gain certification? Proficiency in deploying the 2½-inch line is a fireground necessity whether as a leader line (when it fills out a stretch of 1¾-inch hose) or an attack line. Fireground safety relies on this skill set.

Training Lacking

The problem may be that we are all a product of our training. The officer tasked with leading his engine company will draw from previous knowledge. But, has any of his curriculum mandated proficiency in 2½-inch line operations? I fear the 2½-inch line is misunderstood because of a lack of motivation to train on it and its infrequent use.

|

| (1) The coupling on both of these beds is nearly 10 inches high with no nozzle in sight. (Photos by author.) |

Looking at the hoseline and water application as a simple, routine procedure that does not necessarily have to be mastered tolerates loss of initiative and fosters unpredictable outcomes on the fireground. The large handline is a necessity for all departments. The fire service cannot afford to be apathetic toward competent deployment of this line. The most dangerous scenes await us: the high-rise fire, the commercial furniture shop, or the mill work industrial fire. The weapon we will deploy in an offensive attack on these fires is the 2½-inch handline. We must be prepared, or we will confront inadequacies in the battle.

Research Findings

The flow rates attained from 2½-inch operations led to considerations of how to combat modern fire behavior. Underwriters Laboratories (UL) and the National Institute of Standards and Technology (NIST) have teamed with the International Society of Fire Service Instructors (ISFSI) recently to present findings from the many studies conducted in research labs; Governors Island; Spartanburg, South Carolina; Milwaukee, Wisconsin; and so on. Discussion of these studies point to the benefits of applying streams from a safe vantage point in an effort to “reset the fire.” Resets create increased tenability, allowing crews to proceed with final extinguishment.

Further tests will continue to analyze how safe locations and stream applications relate to the tenability for victims with unprotected respiratory tracts. Some conclusions have been drawn from these studies. By analyzing the data while comparing them with firefighting principles and practices employed by our predecessors for many years, we derive a commonsense mission posture. How should the studies affect our fireground operations?

|

| (2) Stage the rigs with the appropriate tools for either deployment option. |

Conclusions in this article relate modern fire behavior studies to 2½-inch handline applications. Science points to the findings that today’s fires generate exorbitant amounts of energy and that most furnishings carry heavy hydrocarbon-based fuel packages. A modern couch fire produces two megawatts of energy, per recent studies. The UL studies indicate that such energy is enough to induce flashover. The information points to modern flammable materials in households that allow fires to reach preflashover conditions more rapidly. Flow path management is covered as well, but the focus here is on flow rates, not ventilation profiles.

New science does not dictate a new mission. The mission is the same; we don’t put out fires for the sake of extinguishment. The fire will go out whether we arrive or not once all available fuel is consumed. We attack fires to save lives and rescue victims. Property conservation is also a mission but has less inherent risk-laden responsibilities tied to it. When property and firefighter safety become our sole objectives, then the main priority should be cooling from the safest location. The studies directly relate to our 2½-inch operations as they pertain to how quickly we can apply large amounts of water on the rapidly induced flashover. Rate of application is key here. Fighting science with science means we fight a swiftly advancing fire with violent deployment of high-volume handlines. Large fire liberating that much energy demands more copious amounts of water applied rapidly-a basic principle all must understand.

Nuances to Consider

We need to consider a few nuances pertaining to operating larger handlines. The fire, not a crew’s ability to effectively deploy 2½-inch handlines, dictates the flow requirements of the scene. Documentation in regard to fire flow formulas used over the years is listed in the references. National Fire Protection Association standards, critical fire flow rate formulas from the National Fire Academy (NFA), and studies out of Iowa State University by Royer and Nelson provide a foundation for decision making. A reality is that in today’s structures where there is first-floor involvement and three rooms are nearing flashover conditions-porch, living room, and kitchen-2½-inch fire flows are needed. The fire will have a grip on the whole first floor and will extend to the attic through balloon-frame construction by the time a handline is operational. A crew will struggle to achieve a knockdown with low-volume handlines, a consequence realized at several fires where companies chased fire into the attic extension hours after arrival. NFA fire flow requirements for an 800-square-foot print similar to the fire I just described call for approximately 266 gpm to reach a 30-second knockdown-the gold standard for extinguishment in the fire service.

|

| (3) Break off the wye, and disregard the bundle. |

Staging the Rig

The fire service needs to take note of some interesting challenges in deploying the 2½-inch attack line. Deterrents from effective attack include the 100-psi nozzle, extreme height in accessing 2½-inch hosebeds, staging hose loads with no nozzles readily available, and creating difficult deployments with cumbersome apartment bundles attached to hose loads for extended stretches. “Readily” means just that. A line is not an attack package if it’s not situated for rapid deployment. Expecting members to find a nozzle in a separate compartment adds to reflex time. A fire requiring 2½-inch flows may double in size by the time we are assembled for attack without the proper attack package staged. Several options exist. A restructuring of an entire attack bed configuration departmentwide could be an expensive undertaking.

- Option 1. Departments sometimes choose to stage adapters on the end of the 2½-inch line for supplying 1¾-inch handlines in long-stretch scenarios. The adapters can be as simple as a reducer (a 2½-inch female down to a 1½-inch male), a gated wye (one 2½-inch female to two 1½-inch males), or a gated shutoff previous to the wye. The idea here is to facilitate the use of the 2½-inch line in either the supply or attack capacity. You would need to attach the wye to the shutoff. Accomplishing this necessitates a female 1½-inch connection point. Prior to implementing any changes to your attack packages, test your flows to ensure that any of the appliances doesn’t create unexpected results. The changes mentioned are options, especially if your bed and engine design doesn’t allow for reconfiguration.

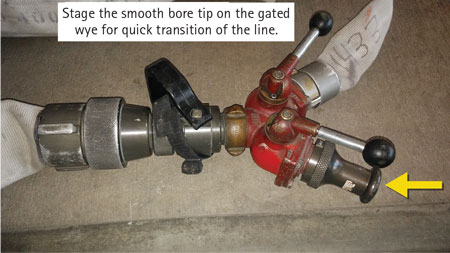

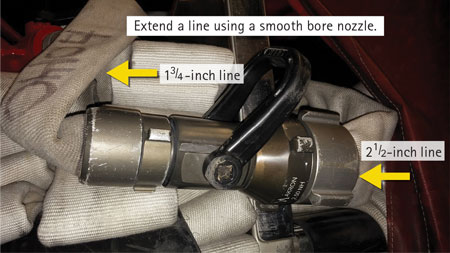

I am not advocating the use of gated wyes on the end of leader lines; I am presenting options when span of control is limited. Keep the current load and adapters, but add a smooth bore tip to the unused discharge of the gated wye. If you use the shutoff before the gated wye option, you will be able to stretch the 2½-inch line with options. Such an option is less costly and will speed your deployment times. The crew looking to deploy the 2½-inch line for increased flows will need to drop the 1¾-inch bundle and add the tip. Photos 2-4 give a visual representation of the procedure:

- Option 2. Split the bed of 600 feet into a 200-foot preconnected “blitz line” and a 400-foot static leader line attached to a bundle. The expense incurred here would be for purchasing additional nozzles; the return would be a currency of seconds when it matters.

- Option 3. When performing company evolutions, we have found that preconnecting the 2½-inch is an attractive option for rapid deployment. Our region is enthralled with preconnected lines; continual practice with this line makes deployment more familiar. A negative to this option is staging too much large line in the fireground perimeter, where much action will be sure to occur. Having a preconnected line dedicated for a large-volume water application saved us one minute in getting water on the seat of the fire. The time was saved by staging a nozzle option as well as preconnecting to the discharge. One minute buys much in the way of property conservation because of rapid fire spread and an increase in life safety factors. Saving one minute of extinguishment time improves future firefighter tenability in a structure and increases safety during overhaul efforts.

Failing to address the feasibility of line deployment will encourage companies to struggle in these large-line attacks. The job of fire service leaders is to stage the rigs for success. Companies need equipment staged for ease of use. When there are too many moving parts in the equation, firefighters will fall back on the habit of using 1¾-inch preconnected line, which could produce undesired consequences. Retired Oakland (CA) Fire Department Captain Dennis LeGear (an authority on hose construction and attack line selection) stated it best: “We must not get bogged down in a system that requires perfect execution; this will lead to failure on the battleground. Where pump operators, officers, and hoseline members are operating in a task-saturated and time-compressed environment, efficient simplicity is the key to effective attack package deployment.”

|

| (4) Remove the tip from the wye and place it on the gated ball valve for 2½-inch flows. |

We have a staffing shortage in our service, yet our core responsibility remains: aggressively advance on the leading edge of every attack. Our duty summons us to explore alternatives that enhance our operational capacities. A large portion of engines in the fire service carry automatic nozzles as the only option for 2½-inch line deployment. Many of these nozzles are rated for 95- to 300-gpm flows. Where will your flow land during the attack? Do you know?

Automatic nozzles requiring 100 psi on a 2½-inch line will halt any initiative a fire company has in use for fire suppression other than sitting on the line in the yard. The pressure these nozzles require make for a rigid water main, unforgiving in flow and movement even to the fittest of firefighters. Handling this nozzle reaction becomes a task of futility. Providing an attack package requiring less pressure and rigidity in the line makes for practical deployment and confronts fireground realities of corners, friction points, and changes of direction. Simply stated: Failing to stage your 2½-inch lines for successful deployment restricts their effectiveness. These limits produce tactical mindsets that tend to use 2½-inch lines as defensive lines for static use only or leader lines for extending 1¾-inch lines.

Fireground Flow Addendum

Not only gpm, but also droplet size, are important considerations when discussing the flow. Fog nozzles have been promoted for the tiny droplets of water that absorb steam, but only convective heat flux is addressed. Fog nozzles can extinguish a contents fire in the rollover stage, but a fire necessitating increased flows is most likely more than just a contents fire. These fires need standoff distance, penetration through heated layers, and low amounts of air entrainment. A fire attacking the structure needs large droplets and penetrating streams that are not prone to evaporation in superheated environments. The solid column of water will not evaporate readily on its way through superheated convective currents and will deliver more gpm at the target, creating rapid knockdown. William Clark describes flashover as a convective and radiant heat flux event, as does NIST in its literature. Fog nozzles may address convective heat waves, but they struggle to reach the seat of the fire because the smaller drops of the broken stream vaporize and are swept away by the thermal column. Convective heat carrying away our stream’s efficacy limits its ability to reach contents unveiling unrelenting radiant heat. Interior structural firefighting needs to employ a nozzle that addresses both of these needs. Fire attack weaponry must address both fireground realities.

|

| (5) Note the preconnect option for a blitz line. |

Nozzle reaction could be at the head of this debate since it affects the nozzleman, who is most responsible to end the event and is also the most vulnerable member in the fight. For years, I felt the need to place a piece of webbing around a 2½-inch line to competently flow it as a single company resource. The time it took to tie the webbing around the line and the difficulties added to line movement made me apprehensive when using it. Placing a low-pressure nozzle on the end of the line resolved this problem.

Here are the nozzle reaction (NR) formulas:

Fog NR:

.0505 Q√NP

NR Q = Gallons per Minute

Solid Bore NR:

1.57 D2 NP

NR D (Diameter of tip) = NP

The NR for a 11⁄8-inch smooth bore tip flowing 266 gpm at 50 psi tip pressure is approximately 99 pounds reaction force.

The NR for a fog nozzle flowing 250 gpm with 100-psi tip pressure is approximately 126 pounds of reaction force.

The issue with the line that once gave me fits and tepidness as a young firefighter because the fog nozzle required excessive pressure for operations has been resolved. The line is now handled and moved with pride largely because of the smooth bore nozzle. Fatigue, apprehension in deployment, and resources needed for handling are all reduced. Two companies are not needed to move this line unless more than four sections must be advanced. This efficiency creates a ripple effect in a large fire event. Requiring fewer companies on the handline makes additional firefighters available to work on other lifesaving assignments. Efficiency in scene management leads to rapid scene stabilization. How many firefighters are needed to handle a 2½-inch line? My research of various sources indicates three firefighters should be able to handle 100 pounds of reaction force. The number goes up only when considering the 100-psi nozzle.

Smooth Bore vs. Automatic Nozzles

Gpm and psi have a stance in the world of stream effectiveness. The baffle/spring feature is ideal for master streams where limited water supplies hamper effective solid streams. The feature is not so ideal for the interior firefighter at the fuel-flame interface. Notes taken in drills indicate an automatic nozzle does a superb job of hiding insufficient flows. The drills examined the effect kinks have on hoselines and gpm flowed. A good looking stream was produced with a 1¾-inch line with an automatic nozzle at 50 gpm.

In situations where initial supply operations provided limited fireground flows, automatic nozzles still produced a stream of reach. The theory is based more on pressure than gpm and critical flow rate. The additional benefit of the automatic nozzle is that spring calibration allowed the baffle to retract to the additional flow acquired later in the incident. The spring baffle mechanism allows for increasing the flow without having to shut down the line and adjust diameter size, as is the case with stacked smooth bore tips in this evolution. The possible restriction of flow on an automatic nozzle in an aggressive offensive interior stance may coax our firefighters to enter immediately dangerous to life or health (IDLH) atmospheres with minimum flow. Smooth bore nozzles communicate a poor quality stream in terms of gpm flow and reach more readily prior to fire attack. While staging for an interior attack, this is a positive feature in that it gives the nozzleman an opportunity to remedy the problem before entering an IDLH atmosphere.

Reach of stream is subjective when comparing these nozzles. When flowing at optimal tip pressures side by side, an automatic fog nozzle can throw droplets farther because of the pressure it’s pumped at and because small ineffective droplets reach an insignificantly greater distance. The smooth bore nozzle will produce effective water applied at a greater distance. Fog nozzles have much rain down from nozzle to target since the droplets are not packed tightly enough to hold them together at length. The smooth bore nozzle aptly produces a penetrating effective stream.

|

| (6) Extend and reduce line size using the gated ball valve. |

Having had extensive experience operating automatic nozzles on 1¾-inch handlines, I came to realize their variable flow rate. When pumped at the manufacturer’s recommendation of 100 psi at the tip, they routinely underperformed in flow. One automatic on my front line engine provided only 180 gpm on a 2½-inch line at optimal pressure, vastly underperforming in the flow largest fire events require. If preference calls for a 180-gpm stream, putting the right nozzle on a 1¾-inch line will produce these results with less labor needed to maneuver the line. While testing different brands of automatic nozzles, I became more concerned.

We conducted two separate tests with optimal tip pressures of 100 psi to the same nozzle. One test provided a flow rate of approximately 300 gpm. The ensuing test conducted within five minutes of the first test garnered approximately 360 gpm from the same automatic nozzle. The variance is common with the automatic nozzle, which is a variable gallonage nozzle. In fact, the automatic nozzle flowing 180 gpm was supplied with an additional 20 psi, at which point we experienced its top flow capacity-300 gpm. A nozzleman would experience a jump in nozzle reaction from 90 pounds reaction force (acquired from a 180-gpm flow) to 150 pounds reaction force (acquired from a 300-gpm flow). I would argue variable gallonage nozzles are dangerous for this reason. Fog nozzle enthusiasts can speak of stream efficacy, but a jump in reaction force by 60 pounds is indefensible. A variable gallonage nozzle has the ripple effect of variable reaction force. The two variables should be controlled, and the firefighter tasked with frontal attack on the seat of the fire should be aware of them.

The unpredictability in flow issue is compounded when master stream devices are used. Vincent Dunn stated flowing 300 gpm and above necessitates considering using mechanical assistance, such as monitor devices, when applying streams. Our goal should be to flow as much as possible given certain limitations such as what the hoselines can flow, what is maneuverable in fire compartments, and the range of nozzle reaction a single crew of firefighters can handle.

A plan that enables companies to protect themselves with an attack package they can manage independently stages them for success. Flows on large handlines require a “sweet spot,” which resides in the 266-300 gpm range provided by a 50-psi nozzle. Tactical options exist for 2½-inch line attacks in residential fires. Smooth bores are functional in ranges of 40 to 60 psi. Underpumping the 11⁄8-inch tip at 40-psi nozzle pressure produces a stream that is still effective for a single-family dwelling fire. Line maneuverability is increased dramatically, and the line still flows more than 230 gpm. For residential attack, plenty of reach is still attained at this pressure, and there are sufficient gpm and vast improvements in maneuverability. To be fair, I’m unaware of any routine maintenance performed on the automatic nozzles tested beyond daily rig checks and company-conducted flow tests. I would be interested to hear how many departments deploying automatics have their springs calibrated per manufacturer recommendations. The measuring devices we used were not calibrated absolutes, but they did provide ballpark figures that were validated later in separate flow testing with sophisticated equipment.

Operational Benefits and Considerations

The fire service is seeing a rejuvenation of smooth bores on the high-rise bundle. Deploying this line with superiority and confidence in a low-frequency event that carries so much risk is vital. By implementing smooth bores commonly on 2½-inch residential ensembles, we will increase our firefighters’ experience and competence with the line, leading to favorable results in a high-rise event. An additional benefit is that you can use the smooth bore nozzle with the 2½-inch line as a break-and-go option. The tip for gated ball valves is a 1½-inch fitting, making it a great line to gain exterior knockdown and to add 1¾-inch line for rapid mopup (photo 6).

Automatic nozzles can weigh up to eight and a half pounds. I have worked with smooth bore nozzles with a 11⁄8-inch tip that were as little as three pounds. Whipping around a nozzle that weighs nearly nine pounds for fire attack will fatigue a firefighter much more rapidly than its three-pound counterpart. Finally, smooth bores are less expensive than automatic nozzles and require virtually no maintenance and calibration, and they are easier to inspect in the field.

|

| (7) Another view of the bundle staged for optional deployment. |

I would argue again that the speed at which we deploy the 2½-inch handline should equal or surpass that for the 1¾-inch line.

Operational windows become condensed in every facet of fire combat. Fully developed fires extend exponentially more quickly than growth-stage fires. These fires destroy more property and greatly impact life safety. Commercial structure fires also require large handlines. Struggling to deploy 2½-inch handlines is a disservice to our commercial client base. A professional engine company should be comfortable and confident in deploying all of its options; fire service leaders need to ensure that we reach this level. We should view the 2½-inch line as a fire attack option. Our equipment is often staged for means other than large attack line deployments. Success depends on maintaining and staging our equipment for mission readiness.

Note: Special thanks to the Hose Deployment and Research Team of the St Paul (MN) Fire Department for the inspirational concepts mentioned throughout the article: Captain Joe Blank and Firefighters Jon Hall, Mic Korba, and Andy Bieze.

Reference resources

Babrauskas, Burkowski, Reneke, Peacock, et al. (1999) “Defining Flashover for Fire Hazard Calculations,” Fire Safety Journal; 32: 331-345. Elsevier.

Fornell, D. (1991). Fire Stream Management Handbook. Saddle Brook, NJ: Fire Engineering/Pennwell Books and Videos.

Dunn, V. (1999). Command and Control of Fires and Emergencies. Saddle Brook, NJ: Fire Engineering/Pennwell Books and Videos.

Bridge, E. and Vestal, J. (2010). “A Quantitative Approach to Selecting Nozzle Flow Rate and Stream, Part 1,” Fire Engineering, Oct. 2010.

Bridge, E. Vestal, J. (2011). “A Quantitative Approach to Selecting Nozzle Flow Rate and Stream, Part 2,” Fire Engineering, Jan. 2011.

Clark, W. (1990). Firefighting Principles and Practices. 2nd Ed. Saddle Brook, NJ: Fire Engineering/Pennwell Books and Videos.

Kerber, S. (2015). “Analysis of Changing Residential Fire Dynamics and Its Implications on Firefighter Operational Timeframes.” Accessed 4/7/15 at: http://newscience.ul.com/wp-content/uploads/2014/04/Analysis_of_Changing_Residential_Fire_Dynamics_and_Its_Implications_on_Firefighter_Operational_Timeframes.pdf.

LeGear, Dennis. “Nozzle Dreams.” Feb. 7, 2013) https://countyfiretactics.com/2013/02/07/the-nozzle-nozzle-dreams/.

LeGear, Dennis. “Hose Dreams.” Nov. 24, 2013). Accessed at https://countyfiretactics.com/2013/11/24/hose-dreams-by-dennis-legear/.

LeGear, D. “Hose Dreams, Part 3.” Fire Nuggets, March-April 2015. Accessed at www.firebytrade.com.

Brush, B. (2015) “Gaining Relative Superiority: The 2½-inch Attack Line.” Accessed at http://firebytrade.com/.

JEFF ROTHMEIER has been a member of the St. Paul (MN) Fire Department (SPFD) for 11 years and is captain of Rescue Squad 3. He is a member and shift coordinator of the Minnesota Aviation Rescue Team. He is lead instructor at Minnesota’s 1st State Fire Academy hosted by Central Lakes College and assistant instructor with the SPFD Training Division and Century College. He has an associate degree in fire science technology and a bachelor’s degree in fire and emergency response management.

The 2 1/2 Inch Handline

Firefighter Training: Training Days: Hoselines

ENGINE COMPANY STANDPIPE OPERATIONS: TACTICAL USE OF 21⁄2-INCH HANDLINES, PART 1

Fire Engineering Archives