BY MEREDITH McQUERRY, ROGER BARKER, ALEXANDER HUMMEL, and SHAWN DEATON

Recent research at North Carolina State University (NCSU) aims to determine the direct impact of additional layers and thickness or bulk on the thermal protection and heat loss qualities of structural firefighter turnout suits. The “Revolutionary Modern Turnout Suit” project, sponsored by the United States Department of Homeland Security/Federal Emergency Management Agency through the Assistance to Firefighters Grant program, is exploring new design features and material innovations to reduce the incidence of heat stress among firefighters. Currently, more firefighters are experiencing injury and even death from exhaustion and heat stress than from burn injuries.

National Fire Protection Association (NFPA) 1971, Standard on Protective Ensembles for Structural Fire Fighting and Proximity Firefighting (2013 ed.), requires thermal protective performance (TPP) and total heat loss (THL) evaluations for new, unused turnout materials. The TPP is an evaluation of the material’s thermal protection, whereas THL is a measure of the fabric’s breathability or comfort. These two measures are inversely proportional to one another; thicker, heavier materials provide better TPP results, but lighter, thinner materials are ideal for THL.

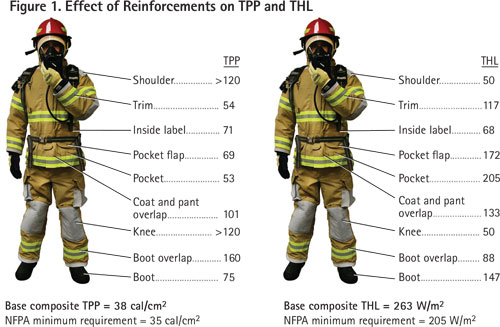

The NFPA requires a TPP rating of at least 35 calories per square centimeter (cal/cm2), whereas the minimum THL requirement is at least 205 watts per square meter (W/m2). The limitation with these two measures as specified in NFPA 1971-2013 is that they evaluate the three-layer base composite only, which includes only the outer shell, the moisture barrier, and thermal liner layers. When the fabric is produced as a three-dimensional garment and worn with a full turnout ensemble [boots, gloves, thermal hood, helmet, self-contained breathing apparatus (SCBA), and so on], the clothing system’s level of thermal protection and heat-loss capabilities changes drastically. Added reinforcements at the knee, the shoulder, the pockets, the trim, and elsewhere are not factored into current TPP and THL evaluations.

Impact of Additional Layers

As part of our research in the Textile Protection and Comfort Center (TPACC) at NCSU, we evaluated the impact of these additional reinforcements in terms of TPP and THL. We selected as a benchmark a standard (the control) turnout suit typical of what departments would purchase on the market today. We made TPP and THL measurements on the base composite and on the garment overlaps (coat and pant, boot and pant) and on the additional reinforcements (pocket, pocket flap, knee and shoulder padding, trim, NFPA label).

Figure 1 demonstrates that most of the turnout suits had much higher TPP ratings than required and, as a result, much lower THL values that do not meet the minimum NFPA requirement. The base composite, used as a control, had a TPP rating of 38 cal/cm2 and a THL of 263 W/m2, which is greater than the minimum requirements. By adding a single layer of outer shell material to represent a pocket, the TPP was increased to 53 cal/cm2 and the THL was reduced to the minimum requirement (205 W/m2). The pocket composite was the only reinforcement evaluated that would pass the minimum THL requirement. The reflective trim increased the TPP to more than 50 cal/cm2 but reduced the THL by 146 W/m2. Among portions with the lowest THL were the NFPA label (identifying the garment’s size, specifications, and so forth), which covers a significant area of the garment and which reduced the THL to 68 W/m2, and the knee and shoulder reinforcements, which further reduced the THL to 50 W/m2. The area with the highest level of thermal protection (160 cal/cm2) in the turnout ensemble is where the boot and pant overlap. This overlap covers a significant amount of the lower leg and reduces the THL to 88 W/m2.

Base Composite Percentages

Although these results demonstrate the impact of standard reinforcements found in many turnout suits on the market today, some departments add even more material to provide additional levels of thermal protection. We analyzed the base composite area on four different turnout suits. The base composite percentage was found by determining the number of reinforcements added to the three-layer base composite. Suit 1 included only the reinforcements required by NFPA 1971, Suit 2 was typical of what a number of departments purchase, and Suits 3 and 4 are unique suits from two American fire departments.

Overall, a typical turnout suit, identical to the one evaluated above, had a base composite (outer shell, moisture barrier, and thermal liner) percentage of just 50 percent. Suits from other areas of the country had as little as a 33-percent base composite area, meaning almost 70 percent of their turnout suit consisted of additional reinforcements, not including the coverage the SCBA provided.

Most of the additional layers and reinforcements were in the front of the coat (Figure 2). The additional layers ranged from one to more than 11 extra layers. The front coat of Suit 1 had a base composite percentage of 52.5 percent; Suit 2, 45.9 percent. Suits 3 and 4, however, were bulked up for even greater protection, with base composite percentages in the front of the turnout coat of just 35.2 percent (Suit 3) and 22.5 percent (Suit 4). These two suits also had the highest number of additional layers throughout the suit.

Findings

Overall, these results illustrate the limitations of fabric level TPP and THL measurements for structural firefighter turnouts. This research found that structural turnout suits provide a level of thermal protection that greatly exceeds the minimum 35 cal/cm2 indicated by fabric level TPP testing. Also, because of increased layering effects, the TPP can exceed 150 cal/cm2 in some locations within the turnout ensemble. Such a drastic increase in TPP leads to a significantly detrimental decrease in heat loss to as low as 50 W/m2 in some areas.

Thus far into the study, the research conclusions demonstrate the imbalance between the garment’s protection and its comfort and the limitations of using fabric level methods for measuring the TPP and the THL. These data illustrate the unintended negative consequences of overspecification and the impact of additional layers on thermal protection. To achieve a more successful balance between thermal protection and comfort, the need for each additional reinforcement and layer should be evaluated to help provide meaningful improvement to the THL in the garment.

MEREDITH McQUERRY is a Ph.D. candidate and graduate research assistant under the direction of Dr. Roger Barker in the Textile Protection and Comfort Center (TPACC) at North Carolina State University. She has research experience in fabric durability, wear life, and clothing comfort physiology applied to structural firefighter turnouts.

DR. ROGER L. BARKER is the Burlington Chair in Textile Technology with the TPACC.

DR. ALEXANDER HUMMEL is a research assistant professor with the TPACC.

SHAWN DEATON is the special projects director with the TPACC.

Thermal Performance and Limitations of Bunker Gear

Demystifying Turnout Gear Terminology

MAINTAINING TURNOUT GEAR

Total Heat Loss

Fire Engineering Archives