BY PAUL SPURGEON

In “Every Pump Operator’s Basic Equation,” (Fire Engineering, October 2012, 51-65), I explained how to properly achieve the discharge pressure for fire attack lines using the equation PDP = NP + FL + APP + ELEV. The article showed how each figure is developed using trial-and-error and mathematical equations to give the pump operator specific, pencil-sharp calculations designed to give an exact answer to the formula. It is of utmost importance to understand how to calculate the formulas using precise calculations. An accomplished engineer must not only understand how to calculate the formulas but also know why the formulas are used. Knowing the thought process behind what the pump operator is calculating is as important as being able to plug numbers into the formulas to obtain an answer.

RELATED FIREFIGHTER TRAINING

- Fireground Pump Operations: Mastering the Panel

- Developing a Fire Stream

- Big City Large Flow Water Delivery Management

However, we can use some shortcuts to make our job easier and perform it more quickly when we are on a fire scene where time is a factor. The crew on the hoseline really doesn’t like to take a beating in a fire while you make time-consuming calculations to supply water to the nozzle. Ideally, the engineer should be able to determine the discharge pressure before the crew can stretch the hoseline-a near impossibility if he needs to figure the entire formula. Predetermined figures determine the nozzle pressure setting: 50 pounds per square inch (psi) for smooth bore handlines; 100 psi for fog nozzles, and 80 psi for master stream smooth bore nozzles. Either the manufacturer sets the appliance friction loss or it is calculated ahead of time using pressure gauges. You can mark these figures down near the pump panel, on the appliance itself, or in both places. You can only determine the elevation on the fireground since each scene is different.

You can quickly figure hose friction loss using the rule of thumb method. Although various rules of thumb exist, they have all been developed by using precise calculations or by testing the hoselines. Friction loss will vary based on the hose’s manufacturer, its condition, and how it is made, so different friction loss formulas yield slightly different answers. To truly determine the amount of friction loss in a hose, you must place a pressure gauge on both ends of the hose and subtract the difference. Of course, you can’t do this on the fireground, so rule-of-thumb guidelines have been developed.

GPM FLOW

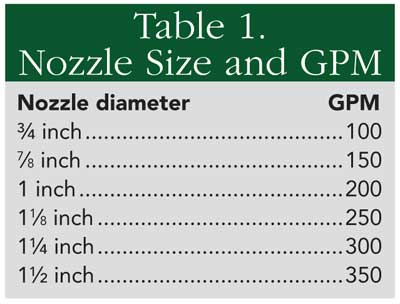

The first rule of thumb isn’t about friction loss but about determining the gallons-per-minute (gpm) flow from smooth bore nozzles. Friction loss depends on the amount of water flowing through the hose. Start by assigning a flow of 200 gpm for a one-inch nozzle. For every 1⁄8-inch increase or decrease in diameter, add or subtract, respectively, 50 gpm (Table 1).

If you calculate the gpm flow using the formula 29.72D2√P (where D is diameter in inches and P is pressure in psi), you will notice a fairly significant difference in the flow rates, which illustrates the difference between precise hydraulic calculations and rules of thumb.

CREATING A PUMP CHART

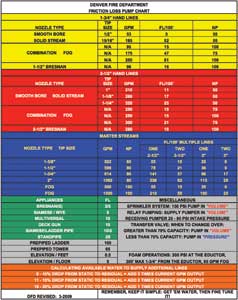

The first method for determining friction loss is to use a pump chart, as do most fire departments. The charts were developed by applying friction loss formulas or by testing the department’s hoselines with pressure gauges. Either way is acceptable. I prefer using pressure gauges, which is more accurate because they measure the friction loss in the actual hose used in the department. Measure the friction loss in all the hoselines your department uses and come up with an average. Although it’s more time consuming and certainly more labor intensive, the results are more precise.

The pump chart can be arranged in any style that works for you, but it should contain certain information. First, divide the chart into sections according to the hose sizes your department uses, and include a master stream section. Under each section, list the nozzle sizes used, their flow rates in gpm, and the friction loss associated with each hose/nozzle combination, listing both smooth bore and fog nozzles. Include a list of the appliances on your apparatus with their respective friction losses. Also include any department standard operating guidelines or procedures you feel are necessary (Figure 1).

| Figure 1. Denver (CO) Fire Department Pump Chart |

|

| Source: Denver (CO) Fire Department. |

The pump chart should list all numbers used in the pump discharge equation. The pump operator plugs the numbers in place and adds or subtracts to come up with the proper discharge pressure.

The pump chart is a very effective, accurate tool. Once the pump operator trains and becomes familiar with it, the calculations will be quick and easy.

THE HAND METHOD

One of the most widely used rules of thumb for determining friction loss is the hand method. This method works for flows from 100 to 500 gpm. It is used primarily for 2½-inch hose but has been adapted to figure friction loss in 1¾-inch hose as well. Once the pump operator practices and becomes familiar with this, it becomes very quick and easy to use. We will begin with the 2½-inch hose (Figure 2).

| Figure 2. The Hand Method (2½-Inch Hose) |

|

Starting with the thumb on the left hand, assign a gpm to the base of each finger. The thumb is 100, the index finger is 200, and so on. Between each finger are the half-hundred gpm (e.g., 150, 250).

Move back to the thumb and assign odd numbers to the tips of each finger, starting with 3 (e.g., the thumb is 3, the index is 5). In between the fingertips are the even numbers.

With the numbers in place, do the math.

- Divide the number at the base of the finger by 100 (e.g., 100 = 1, 150 = 1.5, 200 = 2).

- Multiply that number by the number at the tip to find the friction loss in 100 feet of hose. For example, in a hoseline using a 200-gpm fog nozzle, 200 is at the base of the index finger. Simply divide 200 by 100 to get 2, then multiply 2 by 5, the number at the tip of the index finger. The friction loss in 100 feet of 2½-inch hose flowing 200 gpm is 10 psi.

If 450 gpm is flowing, multiply 4.5 by 10 to come up with a friction loss of 45 psi per 100 feet.

Example 1. Determine the friction loss in 600 feet of 2½-inch hose equipped with a 250-gpm fog nozzle.

- Find 250 on your hand (between index and middle fingers).

- Divide 250 by 100: 250 ÷ 100 = 2.5.

- Multiply 2.5 by 6 (number at tip between index and middle fingers): 2.5 × 6 = 15, or 15-psi friction loss per 100 feet of hose.

- Multiply 15 by 6 (the number of 100-foot hose lengths): 15 × 6 = 90.

- 90 psi total friction loss.

The same method can be used for 1¾-inch hose with some slight modifications (Figure 3). This method is good only for flow rates between 100 and 200 gpm. For higher flow rates, use a larger hose size. In Figure 3, the middle of each finger is labeled with the gpm, and the tip of each finger is labeled 1 through 5, starting with the thumb. Find the nozzle gpm flow and multiply the number at the tip of the finger by 12.

Figure 3. The Hand Method (1¾-Inch Hose)

Example 2. Find the friction loss per 100 feet of 1¾-inch hose equipped with a nozzle flowing 150 gpm. Find the middle finger (150), look at the number at the tip (3), and multiply by 12 to find the friction loss of 36 psi.

Example 3. Find the friction loss in 200 feet of 1¾-inch hose with a 175-gpm fog nozzle.

- Find the finger indicating 175 gpm (fourth finger).

- Multiply the number at the fourth fingertip (4) by 12: 4 × 12 = 48 psi per 100 feet of hose.

- Multiply 48 by the number of hose lengths: 48 × 2 = 96.

- 96 psi total friction loss.

The hand method is pretty simple to use once you get used to it. The key is to practice and train to get proficient with it, as with anything in the fire service.

THE DROP 10 METHOD

The last rule of thumb technique is the one I find is the easiest. It works only for 2½-inch hose. It is called the “Drop 10” method and doesn’t require you to remember any sets of numbers. All you need is to know the gpm flow from the nozzle. This works with smooth bore and fog nozzles.

Take the gpm number and drop the last digit. Subtract 10 from the resulting number, which provides the friction loss for 100 feet of 2½-inch hose.

Example 4. Find the friction loss for a 2½-inch hose with a one-inch smooth bore tip flowing 210 gpm.

- Take 210 and drop the zero = 21.

- Subtract 10 = 11.

- Friction loss = 11 psi per 100 feet of 2½-inch hose.

Example 5. Find the total friction loss in 300 feet of 2½-inch hose equipped with a 185-gpm fog nozzle.

- Drop 5 from 185 gpm = 18.

- Subtract 10 = 8.

- Friction loss = 8 psi per 100 feet of hose.

- Total friction loss = 8 × 3 = 24 psi.

That’s it. It’s that simple. All you need to know is the flow rate of the nozzle being used. The only limiting factor is that it is only good for 2½-inch hose.

••• The rule of thumb methods shown here are useful tools when you are standing at the pump panel and need to get water to the nozzle crew in a hurry. They are quick and relatively accurate. The numbers come close to what is calculated using the Underwriters’ or the coefficient formula. However, the only way to know how much friction loss is in the hose you are using is to test the hose to determine the friction loss exactly. Whatever method you choose, practice it until it becomes second nature to you.

PAUL SPURGEON is a 20-year veteran of the Denver (CO) Fire Department. Promoted to engineer in 1998, he was assigned to Engine 7 in northwest Denver. Spurgeon received an associate degree in fire science and technology from Red Rocks Community College and is the author of Fire Service Hydraulics and Pump Operations (Fire Engineering, 2012).

Enter 154 at fireeng.hotims.com

Originally ran in Volume 166, Issue 2.