By Dave Dalrymple

Although it’s not a glamorous or a high-profile subject, vehicle stabilization is critical at an extrication scene and needs to be considered at all motor vehicle collisions (MVCs). Unwanted vehicle movement is a hazard at an MVC and needs to be addressed like any other scene hazard. Although most vehicles end upright and need only a straightforward process to manage them, a vehicle in an unusual position is a situation that poses an increased hazard for rescuers and first responders. There is also the problem of vehicle construction issues: already suffering from crash damage, many vehicles today lose their structural integrity as firefighters perform tool evolutions and remove vehicle components. This weakening of the vehicle’s structure can assist us, but it is vital to “capture” the vehicle and “secure” it on a solid foundation. Many of the tool evolutions we perform need this foundation from which to work. How can you displace a dash today if your vehicle is not sitting on a solid platform?

Vehicles

The today’s vehicles are constructed affect all of our extrication efforts: patient care, tool operations, and stabilization. The prevalent construction methodology is unibody construction. Basically, the vehicle’s framework is the occupant floor plan; sub-frames are constructed off the front and rear of the vehicle. The rest of the vehicle structure, including the glass, rounds out the structural integrity. As vehicle components are damaged and displaced in a crash, the vehicle’s structural integrity is compromised. The tool evolutions we perform to disentangle a patient may also weaken a vehicle’s structure. As we weaken the vehicle, the vehicle can twist, bend, and contort, even if it is sitting on its wheels. This movement can trap doors previously opened; add tension to glass so that it “explodes” with magnified force when we break it; and even trap an occupant’s feet or legs more by folding the footwell/firewall area. Placing the vehicle on a “platform” and securing it minimizes the hazard, manages it better, and improves our tool evolutions.

Ride height, the distance between the underside of the vehicle and the ground, is another aspect to consider in today’s vehicles. In the past, most of our stabilization was handled by step chocks (if the vehicle is upright). Step chocks are purpose-made cribbing blocks built into a stair step fashion. Two of the most popular vehicle types today are sport utility vehicles (SUV) and minivans. These vehicles tend to have a higher ground clearance (and higher center of gravity). Many times, step chocks alone will not have enough height to properly capture and secure a vehicle. Usually, rescuers have to build a small box crib under the step chock for it to work well.

On the opposite end, many cars today are much lower to the ground. In fact, some vehicles are low enough that many times when we insert a step chock under the vehicle, we get only a few “steps” in and under the vehicle, leaving most of the step chock sticking outside the vehicle and becoming a trip hazard for us. Couple this with the fact that vehicles readily absorb energy when struck in a crash. This energy absorption principle can affect the vehicle by basically absorbing a certain amount of crash energy (or “crush”), including the drivetrain and even tires. The result is that the vehicle ends up sitting on the ground. How do we put a step chock under that? You might say, “Why bother? It’s sitting on the ground!” However, rescuers need to manage the vehicle and control ourselves to ensure it is mitigated properly. Consider also the modern feature of “run-flat” tires or tires with air-monitoring/supplementation. How well can you deflate a “run flat” tire today?

Tools and Methodology

Cribbing, wedges, and step chocks make up our primary stabilization cache. Firefighters use cribbing of various sizes day in and day out at a wide variety of incidents. Wedges fill up gaps and voids. We discussed step chocks a bit already in this article. All these components may be made of plastic as well as wood.

Let’s also look at some of the new and revisited concepts and tools for stabilization. Step chocks evolved from extrication challenges back in the 1980s to assist with rapid stabilization of a vehicle on its wheels. Today, it’s the same, although the process has some additional options to help us. One is the “Rapid Stair” chock from ResQTech. This chock appears similar to a step chock; however, it has a unique process to provide quick stabilization. It is a two-piece plastic device composed of a large chock with an incline plane instead of a stair. The other part is a “traveling block” that has a mirrored incline plane to the large chock topped off with a large flat platform. Each of the incline planes have “teeth” that lock together when pressed. The “rapid stair” is placed much like a step chock; however, the “traveling block” is placed near the base of the large stair. When the “rapid stair” is placed under the vehicle, the “traveling block” is slid upward on the large stair, wedging the traveling block between the large stair and the underside of the vehicle. This step maximizes contact between the vehicle underbody and the ground. This device makes for rapid setup, stabilization, and securing of the vehicle.

Another type of chock is a “quick chock,” which is comprised of two pieces. The first piece is a platform of three or four 4×4 cribs that are 18 inches long. They are screwed and glued together with a top plate of ½-plywood screwed on top of the platform. The second piece is a 6×6 or 4×6 wedge approximately 18 inches long. The quick chock is also placed under the vehicle like step chocks, with the platform being the base and the wedge driven between the platform and the vehicle underbody. This allows for rapid setup and a flexible approach, since depending on ride height and vehicle damage, you can add or subtract components to fill in space to stabilize.

Another idea that deserves a revisit is the lock block-style of cribbing. This crib is made of plastic and manufactured by a variety of companies. These cribs basically look like square or rectangular children’s building blocks of various heights that “nest” or lock together. They provide for a large contact base and can be built and slid under the vehicle to create a “column” of cribbing of variable heights. Also, there are wedges that are made to “mesh” with these blocks.

All these adjuncts work well with the changes in the vehicle dynamics involved when these vehicles are crashed and interact with the tool operations we perform. They all provide for a more rapid and complete stabilization of vehicles upright on their wheels.

Also what about those vehicle tires? Think of the extremes we see out on the street today: ultra high-performance tires that have almost no side wall to the newest “run flat” tires to the large sidewalls of SUV and pickup tires, not including any aftermarket modifications. When we crib the vehicle, we capture the vehicle and its suspension, spreading that point of contact over a large area of the ground. However, depending on the vehicle’s tires, we can still generate movement by “flexing” the tires’ sidewalls. Some of these sidewalls can be fairly large, and this movement can rock the vehicle off its platform we have created with our stabilization evolutions. This unwanted movement can be caused by accessing the vehicle or even tool evolutions. Remember, we need to minimize this unwanted movement to care for our patients. So how do you deflate these tires? There are many options; however, rescuers should strive for a controlled release of air from the tire (stabbing the tire side wall is not advised.) Unscrewing the valve core from the stem, pulling or cutting valve stems, or using a purpose-made tire deflation tool are good choices.

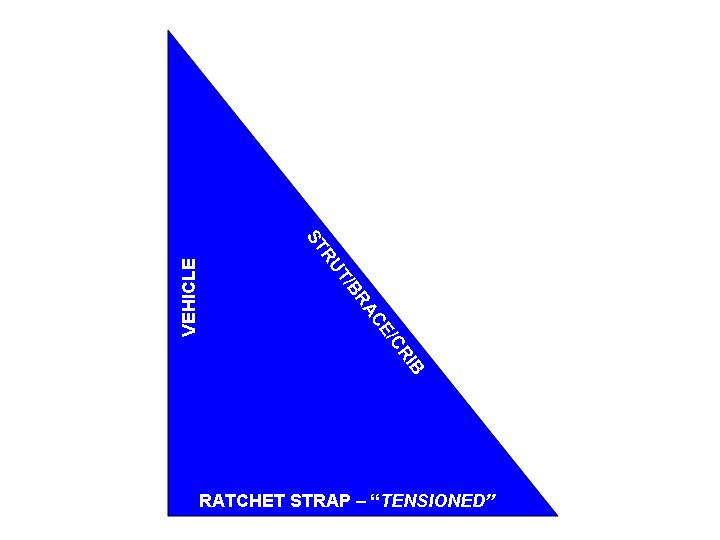

In the past, besides cribbing we relied on adjunct tools such as high-lift jacks, come-alongs, and even lifting bags to assist in our stabilization efforts. Although these items still give us options today, the trend today is to use a technique called “tension-buttress cribbing.” This approach resolves and mitigates stabilization of vehicles on their sides, overturned, or in an unusual situation. The concept involves placing one or more right triangles against the vehicle–a strut or brace with a ratchet strap to the vehicle and then tensioning the strap. This action basically extends the base of contact with the vehicle and the ground.

There are many variations of this stabilization principle, from a simple homemade long crib with a ratchet strap; a section of cribbing with a manufactured base and strap combination and crown or cap; or a manufactured strut, base and strap combination. All use the principle of tension-buttress cribbing, which allows us to “capture” a vehicle and hold it in place effectively and rapidly.

This concept is very simple and straightforward to learn and apply in a variety of situations. The devices themselves also lend well to being stored on a variety of apparatus, and some have extensive accessories to enhance application options. Depending on vehicle orientation, this principle can be applied to stabilize the vehicle in less than two minutes. Depending on the device used, they also can provide a source of controlled lift while stabilizing.

**

Some of these items, “widgets,” and ideas mentioned chop away at that all-important scene time, making our extrications more rapid. They also increase safety by making the vehicle rock solid. We need to save time so that we can improve our patient’s outcome. We also want to try and ensure a safe working environment for rescue personnel. Always recheck your cribbing and stabilization after every major action done on the vehicle (i.e., roof removal, side evolution, for example.)

Although these tools and techniques aren’t necessarily cool or glamorous, vehicle stabilization is critical when we have patients in the vehicle and need to perform space-making tool evolutions.

DAVID DALRYMPLE is a career EMS provider for the RWJUH Emergency Medical Services in New Brunswick, New Jersey, and a volunteer firefighter/EMT/rescue technician for Clinton (NJ) EMS/Rescue. He has been actively involved with emergency services for 27 years. He is the education chair of the Transportation Emergency Rescue Committee-US (TERC), is a certified international level extrication assessor, and serves on the Expert Technical Advisory Board of the IETRI as their road traffic accident advisor. Certified as a NJ fire service instructor, he has been teaching transportation rescue topics for more than 16 years. He is the executive educator for Roadway Rescue LLC, an educational team for transportation rescue training. He is an ICET (Netherlands) certified registered International SAVER instructor. He writes on “Extrication Tactics“ for Fire Engineering and contributed to Fire Engineering‘s Handbook for Firefighter I and II (2009). He received the 2007 Harvey Grant award for excellence in rescue education. He is featured in “Training Minutes“ on vehicle extrication on fireengineering.com.