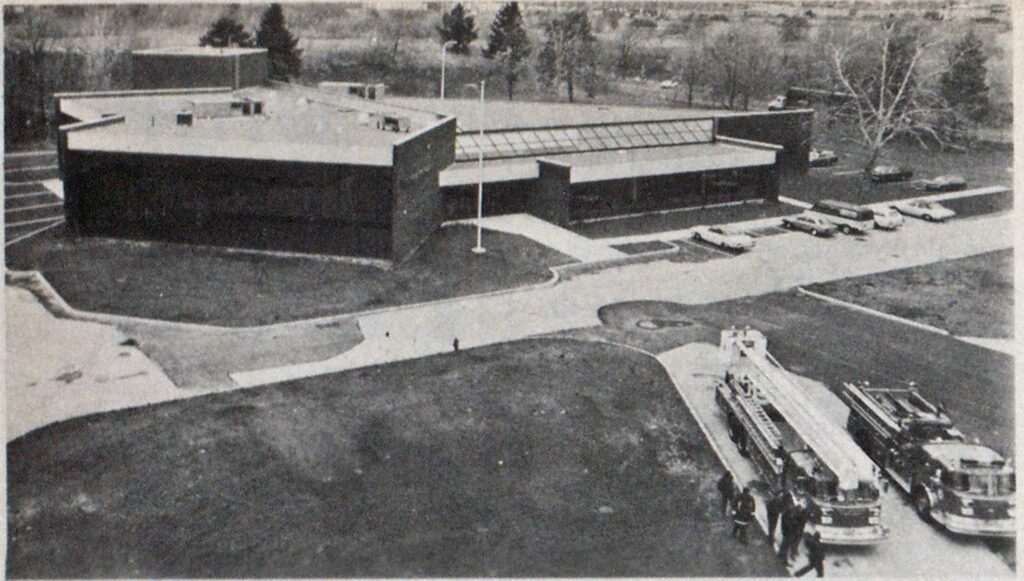

Philadelphia Fire Department Opens New Training Facility

A new fire academy has been constructed for the Philadelphia Fire Department. It’s being called a regional training center by Fire Commissioner Joseph Rizzo, “with the hope that volunteer units in the three-county area surrounding Philadelphia will make use of its accommodations.” Industrial units received a similar invitation.

Finding an acceptable site for a fire training facility is difficult. It had to have room for units to operate. It had to l>e located in an area where smoke and water would not annoy neighbors. Yet it had to be accessible to all areas of Philadelphia, which stretches 35 miles from northeast to southwest.

An ideal location was found on some property already owned by the city water department located next to the police academy along the Delaware River. The site on the river edge afforded the opportunity for training with marine units as well as providing an ideal draft ing spot. Further, it was just off 1-95 and easy to get to.

The budget for the new academy was set at $2.3 million. The first phase was the construction of a driver training course, which was completed before the rest of the academy.

Training tower

The training tower is a concrete and block building five stories in height with an average of 2280 square feet per floor. The tower was built to encompass any fire situation that may arise.

A portion of the first floor features a taxpayer-type storefront with windows. Throughout the building are various kinds of windows which a fire fighter might encounter, from double hung to types found in a high-rise office building or a housing project. Portions of an interior wall are covered with dry wall construction. A section of the building is designed to simulate shipboard construction having hatchway doors with locking dogs. There is an opening, first floor to roof, which can simulate a laundry chute or an incinerator. A section of the roof has wood panels that can be chopped out or cut away with power saws and then easily replaced. The building is completely equipped with standpipes and sprinklers, although the sprinkler system is dry unless charged, due to winter weather conditions.

SCBA maze

The first floor also contains a smoke maze for SCBA training. It features lighted panic safety switches so that if a fire fighter becomes disoriented, the smoke is quickly exhausted to the exterior and a rescue team can be sent in.

There are both drains and scuppers on all floors to evacuate water when hose streams are used. A complete fire escape goes up one side of the building. One side has overhead garage doors and the other has a safety net under the high portion of the building used for ladder and rope training. There is room to maneuver equipment around the building on all sides.

A drafting pit is provided for pump training and pump testing. The water baffles down from the high side of the pit so that no turbulence is created while drafting. Included with the pit is a new device for testing gallonage, eliminating the use of a Pitot tube.

There are three pits, each 20 X 40 feet, for flammable liquid fires. These are fed from three 4000-gallon underground tanks, two holding diesel oil and one for unleaded gasoline. No slop oil is used. Three pumps located under the control tower feed the banks, and controls are located within the house, which is a 12 X 12-foot elevated aluminum structure.

Environmental requirements

The pits are equipped with a smoke suppression system to satisfy the environmental requirements of the air pollution commission. Any spillage from the oil pits is collected in a sewer system that returns the oil and gasoline to a grease separator system consisting of four tanks, from which it is eventually picked up.

Constructed near the river end of the complex is an outdoor classroom which consists merely of a concrete platform with a roof. It is open on all four sides. It provides a place to take a class out of the hot sun rather than march them back to the building for a discussion.

Located throughout the complex are numerous live fire hydrants along with several dummy high-pressure hydrants placed on an 8-inch underground line. To use the high-pressure hydrants, they are charged by a pumper operating from a low-pressure hydrant as its water source, or by a marine unit. In this manner, training on the use of the Philadelphia high-pressure water system can be conducted.

Refresher training

Two engines and a ladder company are sent to the academy on two consecutive working days of each week for refresher training, in which they are expected to perform certain maneuvers or evolutions. Deficiencies in any area are noted, and specialized corrective training programs are implemented.

Simultaneously, two more engines and a ladder attend the defensive driver training program. While these units are at the academy, their stations are covered by other personnel using “series 100” pumpers and ladders, which are second line pieces maintained fully equipped.

During periods of recruit training lasting seven weeks, with three additional weeks for EMT training, a class size of 60 can be accommodated.

Construction details

The administration building contains 21,875 square feet on the main floor and 5000 square feet on the mezzanine. It is steel frame on continuous concrete spread footings, slab on grade. Walls are brick, with interior Walls of a special ground-faced concrete aggregate block. Portions of walls in the lunchroom and another area are of aluminum curtain with glass inserts.

The roof is an insulated 5-ply built-up roof with asphalt covering. Floors are of concrete. However; the classrooms are covered with vinyl Corlon tile, the offices are carpeted and the halls have quarry tile.

Heating is supplied by oil-fired boilers with baseboard radiation. A unique feature of the heating and air-conditioning system is that they are controlled by a company that provides remote service from King of Prussia, some 25 miles from the building. There they constantly monitor and control every operational device in the academy electronically. The building is programmed according to a schedule supplied by the director. He can call and delete energy used from unused rooms. This is part of Rizzo’s department-wide plan to conserve energy.

Smart sensors

There are two air-conditioning units on the roof, and temperatures within the rooms are controlled by sensors. The entire administration building is air conditioned except for the garage/apparatus room.

The first-floor entrance area contains a simulated watch desk. On the right side of the building is the main auditorium (capacity 300) and four classrooms. Within the main auditorium is a stereo-cassette tape deck that can play a tape into the main auditorium or classrooms. It can tape a program only from the main auditorium.

During refresher courses, classrooms contain such items as a cutaway pump, pump simulator, chlorine capping devices, water drills, etc., for use by the instructors.

One classroom is designed for emergency medical training. It is anticipated that all future trainees who go through the academy will take three weeks additional EMT training under a captain and an emergency medical service officer.

A dining area, locker and shower areas for both men and women trainees, equipment storage room, apparatus room and a garage are provided. Within the garage area there is a simulated fire escape, and its height permits the raising of a 35-foot ladder, so that in extremes of weather this area can be used for training.

On the second or mezzanine floor there are offices for the director of training, administrative training officer, safety officer, a driver training officer and lieutenants assigned to the academy. There is also a conference room, staff kitchen, mechanical room and a reception area.

Detectors, of course

The building is fully protected by a fire and burglar alarm system connected to the fire communication center. I he building is zoned into eight areas with a fire alarm box (pull station) located at every exit. All window openings are covered by smoke detectors, and heat detectors are located throughout all eight zones. A light on each detector signifies which unit sounded the alarm, and a box alarm is immediately transmitted. Engine 46 and responding battalion chiefs have keys to the building.

The industrial fire prevention division of the department has conducted training courses for industrial companies having their own fire brigades. Companies are encouraged to send one or two men at a time. In this way, a diversified group is formed. Classes are limited to 40, with a ratio of one instructor to 10 people for classes. Thus far, Philadelphia Electric Company, Smith/Kline, Allied Chemical, Rohm and Haas, the major oil refineries and others have taken advantage of this opportunity for the training of their personnel.

Formal dedication of the academy was on May 8. Looking ahead, it is planned for various activities to be conducted at the academy during the 1982 conference of the International Association of Fire Chiefs to be held in Philadelphia.

On the drawing board for a second phase of construction are a pier and docking facilities for marine units.